How to Control the Cutting Force of Tungsten Carbide Die?

In the field of die manufacturing, tungsten carbide die is the preferred material for many enterprises due to its high hardness, high strength, and excellent wear resistance. However, the high […]

In the field of die manufacturing, tungsten carbide die is the preferred material for many enterprises due to its high hardness, high strength, and excellent wear resistance. However, the high hardness characteristic of tungsten carbide is like a double – edged sword. It generates relatively large cutting forces during the cutting process, which undoubtedly adds numerous difficulties to the machining operation. The effective control of cutting forces is of great significance for ensuring machining quality, extending the service life of cutting tools, and reducing production costs. Next, this article will deeply analyze how to precisely control the cutting force of tungsten carbide die.

Generation and Impact of Cutting Force

Cutting force is the force generated by the interaction between the cutting tool and the workpiece during the cutting process. In the machining process of tungsten carbide die, the magnitude of the cutting force directly affects the wear rate of the cutting tool, the machining accuracy of the workpiece, and the surface quality. Once the cutting force is too large, the cutting tool will wear rapidly and may even experience chipping, which will greatly affect the machining efficiency and increase the machining cost. At the same time, an excessively large cutting force may also cause workpiece deformation, resulting in a significant reduction in machining accuracy and making it difficult for the manufactured die to meet high – standard quality requirements.

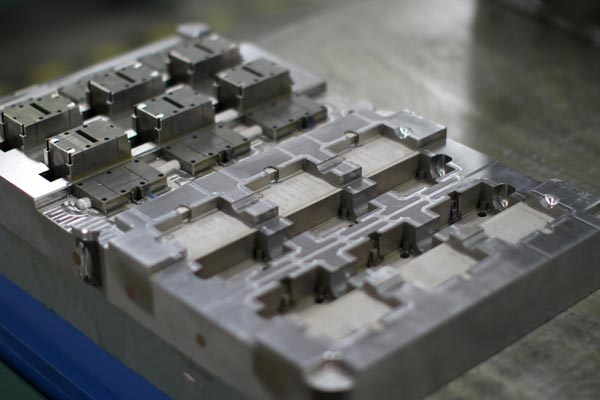

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Methods for Controlling Cutting Force

Select Appropriate Cutting Tool Materials

The selection of cutting tool materials is a key step in controlling the cutting force. Given the high hardness characteristic of tungsten carbide, we should choose cutting tool materials with high hardness, high wear resistance, and high thermal stability. For example, cemented carbide cutting tools, ceramic cutting tools, and superhard material cutting tools are all good choices for machining tungsten carbide. These cutting tool materials act like a solid shield, effectively resisting the high – hardness impact of tungsten carbide, reducing wear during the cutting process, and thus lowering the cutting force to provide a stable guarantee for machining.

Optimize the Geometric Parameters of the Cutting Tool

The geometric parameters of the cutting tool, such as the rake angle, relief angle, and inclination angle, have a significant impact on the cutting force. By carefully optimizing these parameters, we can cleverly reduce the resistance during the cutting process and thus lower the cutting force. Taking the appropriate increase of the rake angle of the cutting tool as an example, this measure can reduce the friction between the chip and the rake face, just like laying a lubricated track between the cutting tool and the chip, making the cutting process smoother and thus reducing the cutting force. At the same time, a reasonable setting of the inclination angle also helps to reduce the cutting force and improve the stability of the machining process, making the machining operation more stable and reliable.

Reasonably Adjust the Cutting Parameters

Cutting parameters, including cutting speed, feed rate, and depth of cut, are key factors affecting the cutting force. When machining tungsten carbide die, we need to adjust these cutting parameters reasonably according to the actual situation. Generally speaking, reducing the feed rate and depth of cut can effectively reduce the cutting force, but excessively low feed rate and depth of cut may lead to a significant reduction in machining efficiency. Therefore, we need to determine the optimal combination of cutting parameters through repeated experiments while ensuring machining efficiency, achieving a perfect balance between the cutting force and machining efficiency.

Make Good Use of Cutting Fluid

Cutting fluid plays multiple roles in the machining process, including cooling, lubrication, and cleaning. In the machining process of tungsten carbide die, using an appropriate cutting fluid is like injecting a clear spring into the machining process. It can effectively reduce the temperature of the cutting area, reduce the friction between the cutting tool and the workpiece, and thus reduce the cutting force. At the same time, the cutting fluid can also help remove chips and keep the machining area clean, avoiding interference with the machining caused by chip accumulation and further improving the machining quality, making the manufactured die more perfect.

Adopt Advanced Machining Processes

With the rapid development of science and technology, more and more advanced machining processes have emerged like bamboo shoots after a rain and have been widely applied in the field of die manufacturing. For example, high – speed cutting technology reduces the cutting force by increasing the cutting speed while significantly improving the machining efficiency, making the machining process more efficient and fast. In addition, new machining processes such as ultrasonic vibration cutting and laser – assisted cutting also show strong advantages. They can effectively reduce the cutting force and improve the machining quality, bringing breakthroughs to the machining of tungsten carbide die.

Practical Application and Case Analysis

Take a certain die manufacturing enterprise as an example. This enterprise faced problems such as excessive cutting force and unstable machining quality during the machining of tungsten carbide die. To solve these problems, the enterprise comprehensively applied the above – mentioned multiple methods. First, they carefully selected high – performance cemented carbide cutting tools to provide a solid hardware foundation for machining. At the same time, they optimized the geometric parameters of the cutting tools to make the cutting tools more handy during the cutting process. In addition, according to the characteristics of tungsten carbide, they reasonably adjusted the cutting parameters and used special cutting fluids to further reduce the cutting force and machining temperature. Finally, the enterprise also boldly introduced high – speed cutting technology, greatly improving the machining efficiency and machining quality. Through the implementation of these measures, the enterprise successfully controlled the cutting force within a reasonable range, not only reducing the wear rate of the cutting tools and extending their service life but also significantly improving the machining accuracy and surface quality of the tungsten carbide die, making its products more competitive in the market.

Conclusion and Prospect

The control of cutting force is undoubtedly a key link in the machining process of tungsten carbide die. By carefully selecting appropriate cutting tool materials, optimizing the geometric parameters of cutting tools, reasonably adjusting cutting parameters, making good use of cutting fluids, and actively adopting advanced machining processes, we can effectively control the cutting force, improve machining quality and efficiency, and create greater value for die manufacturing enterprises. With the continuous progress of science and technology and the continuous emergence of new machining processes, we have full reason to believe that in the future die manufacturing industry, the control of cutting force will be more precise and efficient. This will inject strong impetus into promoting the development of the entire die manufacturing industry and make it焕发 (should be “radiate”) new vitality in the fierce market competition.

In addition, for die manufacturing enterprises, continuous technological innovation and R & D investment are indispensable. Only by constantly exploring and practicing new machining methods and technologies can they remain invincible in the ever – changing market. At the same time, enterprises should also attach great importance to talent cultivation and team building and build a high – quality and professional technical team to provide solid talent support for the sustainable development of the enterprise.

In conclusion, controlling the cutting force of tungsten carbide die is a systematic project that requires comprehensive consideration of multiple factors. By comprehensively applying various methods and technical means, we can effectively control the cutting force, improve machining quality and efficiency, and contribute our own strength to the vigorous development of the die manufacturing industry.

Related Posts

- Exploring the Causes and Prevention Measures of Deformation in Tungsten Carbide Dies

- Application and Special Requirements of Tungsten Carbide Die in the Electronics Industry

- Analysis of Common Faults and Countermeasures of Tungsten Carbide Die

- How to Comprehensively Ensure the Stability of Tungsten Carbide Dies under High Loads