Secrets to Prolonging the Service Life of Tungsten Carbide Dies

In the grand arena of industrial production, tungsten carbide dies are like valiant warriors. With their high strength, high hardness, and excellent wear resistance, they play an irreplaceable and crucial […]

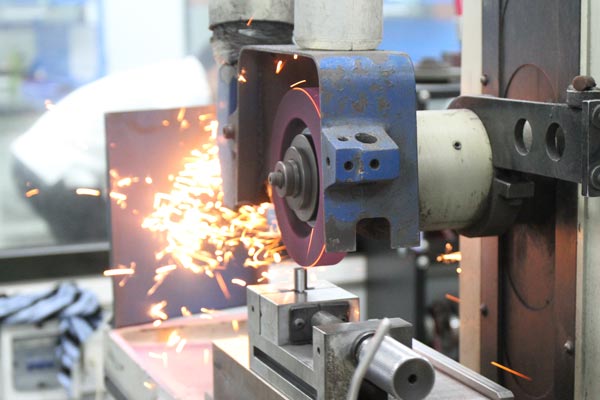

In the grand arena of industrial production, tungsten carbide dies are like valiant warriors. With their high strength, high hardness, and excellent wear resistance, they play an irreplaceable and crucial role in numerous production processes. However, even though these warriors are of exceptional quality, they are still prone to damage risks during long – term use. Once a die is damaged, it will not only affect production progress but also cause unnecessary economic losses. To help tungsten carbide dies continue to “fight” in the industrial battlefield and extend their service life, this article will comprehensively analyze how to avoid damage to tungsten carbide dies during use and present a series of practical tips and suggestions.

1. In – Depth Analysis of Damage Causes

Before exploring ways to avoid damage, we need to uncover the mystery behind the damage of tungsten carbide dies and understand their common causes. These causes are like hidden “traps” that can easily “injure” the dies if we are not careful.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Overloading: Using the die beyond its load – bearing capacity, such as applying improper impact force or pressure, is like forcing a person to carry an excessively heavy burden, making them unable to bear it. For example, when an inappropriate and powerful impact force or excessive pressure is applied during use, the internal structure of the die will be severely damaged, leading to breakage.

- Improper Operation: Incorrect installation, disassembly, or adjustment of the die is similar to randomly placing building blocks when building a delicate block castle, which will eventually make the castle unstable. If operators lack professional knowledge and experience and fail to ensure a precise match between the die and the equipment during installation, or operate improperly during disassembly and adjustment, it can directly damage the die.

- Lack of Maintenance: After long – term use, the die is like a hard – working laborer who needs proper rest and care. If regular maintenance and upkeep are not carried out, the various components of the die will gradually wear out and age, and its performance will be greatly reduced, eventually leading to damage.

- Material Defects: Problems existing in the die material itself, such as inclusions and cracks, are like potential diseases in the human body that can suddenly flare up under certain conditions. These defects will reduce the strength and toughness of the die, making it more prone to damage during use.

- Environmental Factors: Exposing the die to a humid or corrosive environment is like exposing metal to wind and rain, which will accelerate its rusting and corrosion. The moisture and chemicals in the environment will react chemically with the surface of the die, destroying its structure and causing damage.

2. Practical Tips for Avoiding Damage

After understanding the causes of damage, we can take targeted measures to avoid damage to tungsten carbide dies.

- Reasonable Die Selection: The Wisdom of Tailoring to the Situation

Select the appropriate die type and specification according to actual needs, just like choosing the right tool for different tasks. Avoid overloading and ensure that the die can work normally within its load – bearing capacity. At the same time, strictly control the quality of the die material and carefully check to ensure that there are no obvious material defects, laying a solid foundation for the long – term use of the die. - Correct Installation and Debugging: A Meticulous Start

Before installing the die, carefully check the compatibility between the die and the equipment, just like a detective carefully examining every detail. Follow the manufacturer’s installation instructions and use professional tools for installation and debugging, similar to cooking a delicious meal according to a precise recipe. During the debugging process, gradually increase the pressure and speed to avoid sudden impacts and overloading, allowing the die to enter the working state smoothly. - Standardized Operation Procedures: Orderly Actions

Develop detailed and scientific operation procedures and provide professional training to operators, just like providing soldiers with detailed combat manuals and strict training. Ensure that operators strictly follow the prescribed operation procedures and safety regulations when using the die, and avoid applying excessive force or performing improper operations on the die, allowing the die to operate in a safe environment. - Regular Maintenance and Upkeep: Considerate Care

Establish a regular maintenance and upkeep system for the die, just like making a regular maintenance plan for a car. Regularly check the wear condition of the die, promptly detect and replace severely worn components to prevent minor problems from developing into major failures. Clean and lubricate the die to reduce friction and wear, keeping the die in the best condition at all times. - Optimized Use Environment: Creating a Comfortable Home

Keep the use environment of the die dry, clean, and well – ventilated, creating a comfortable working environment for the die. Avoid exposing the die to a humid or corrosive environment for a long time, just like providing a suitable growth environment for flowers. Control the temperature and humidity in the warehouse where the die is stored to prevent the die from rusting and corroding and extend its service life. - Timely Response and Repair: Racing Against Time for Rescue

During use, closely monitor the state changes of the die, just like a doctor closely monitoring a patient’s condition. Once damage or a fault is detected in the die, immediately stop using it and conduct professional inspection and repair. Avoid continuing to use the die when it is already damaged to prevent further losses, just like how continuing to engage in strenuous exercise when a wound has not healed will worsen the injury.

3. Points to Note in Practical Applications

In addition to the above tips, we also need to pay attention to the following details in practical applications to ensure the safe and stable operation of tungsten carbide dies.

- Record – keeping and Tracking: Establishing a “Health Record” for the Die

Establish a comprehensive die use record system to track the use condition and maintenance history of the die in detail, just like establishing a health record for each person. Through these records, we can promptly detect problems and take corresponding measures, providing a solid basis for the maintenance and management of the die. - Training and Education: Enhancing the “Professional Competence” of Operators

Regularly provide training and education on die use and maintenance to operators to improve their professional skills and awareness, just like providing continuous training and guidance to soldiers. Only when operators have professional knowledge and skills can they better use and maintain the die and reduce the occurrence of damage. - Backup and Replacement: Preparing for Unexpected Situations

For dies on key production lines, it is advisable to prepare backup dies to deal with unexpected situations and ensure the continuity of production, just like preparing backup equipment for important events. The backup die can take over in time when the main die fails, avoiding production interruptions. - Technological Innovation and Upgrading: Keeping Pace with Industry Development

Pay attention to technological innovation and upgrading trends in the industry and timely introduce new technologies and materials to improve the performance and service life of the die, just like constantly upgrading weapons and equipment. Through technological innovation and upgrading, we can enable tungsten carbide dies to play a greater role in industrial production.

4. Looking Forward to the Future: Continuous Improvement of Die Performance

Avoiding damage to tungsten carbide dies during use is a systematic project that requires a comprehensive consideration of multiple aspects, including die selection, installation, operation, maintenance, and use environment. By implementing the above tips and suggestions, we can effectively extend the service life of the die, improve production efficiency, and reduce production costs. At the same time, enterprises should also formulate targeted measures and plans according to their actual situations to ensure the safe, stable, and efficient operation of the die. In the future industrial development, with the continuous emergence of new materials and technologies, we firmly believe that the performance and service life of tungsten carbide dies will be further improved, injecting more powerful impetus into the development of industrial production. Let us work together to strive for the “longevity” of tungsten carbide dies and jointly create a bright future for industrial production!

Related Posts

- Tungsten Carbide Die: A “Potential Star” in the Environmental Protection Field

- Comprehensive Analysis of Key Points in Cooling Channel Design for Tungsten Carbide Dies

- Analysis and Countermeasures of Stress Concentration Problem in Tungsten Carbide Die

- What Are the Measures to Prevent Corrosion of Tungsten Carbide Dies?