Stress Concentration in Tungsten Carbide Dies

In the vast landscape of industrial production, tungsten carbide dies, renowned for their high hardness, high strength, and excellent wear resistance, play a pivotal role and are widely applied in […]

In the vast landscape of industrial production, tungsten carbide dies, renowned for their high hardness, high strength, and excellent wear resistance, play a pivotal role and are widely applied in numerous production processes. However, much like a shining star with hidden blemishes, stress concentration issues frequently arise during the use of tungsten carbide dies. These issues act as concealed “assassins,” not only ruthlessly reducing the service life of the dies but also potentially triggering severe production accidents, causing significant losses to enterprises. Therefore, delving deep into the root causes of stress concentration in tungsten carbide dies and exploring practical prevention measures are of paramount importance for ensuring the stable operation of the dies and enhancing production efficiency.

I. Exploring the Root Causes of Stress Concentration in Tungsten Carbide Dies

1. Hidden Dangers within the Material Itself

Although tungsten carbide materials boast superior performance, they are not entirely flawless. Non-continuous defects such as inclusions, pores, and cracks may lurk within the material. These seemingly insignificant defects can serve as “triggers” for stress concentration during the long-term use of the dies. When the die is subjected to stress, these defect sites become the first to accumulate stress, causing the die to fail under stress levels far below its normal bearing capacity. Especially when these defects are located in high-stress areas of the die, their weakening effect on the die’s strength is even more pronounced, akin to a crack in the foundation of a building that could lead to its collapse at any moment.

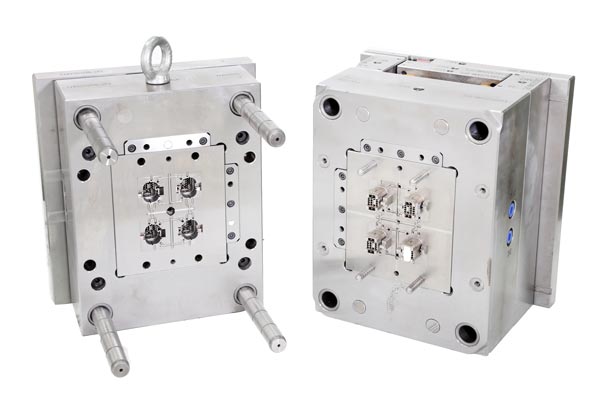

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

2. The Wounds of Design Flaws

Unreasonable die design is another significant factor contributing to stress concentration. In the die structure, the presence of excessive sharp corners, abrupt cross-sections, or holes can act as “traps” for stress. Under stress, the stress at these locations rises sharply, much higher than that in surrounding areas, resulting in stress concentration. Additionally, insufficient stiffness design of the die is also a concern. When the die undergoes significant deformation during use, the internal stress distribution changes, and stress concentrates in certain areas, accelerating die damage.

3. Imperfections in the Processing Stage

Negligence during the die processing stage can also sow the seeds of stress concentration. During cutting operations, improper selection of cutting parameters, such as excessive feed rates or cutting depths, or the use of severely worn tools without timely replacement, can lead to the formation of micro-cracks on the die’s surface or inside. These micro-cracks are like hidden “time bombs” within the die, gradually expanding under the continuous action of stress during subsequent use and eventually triggering stress concentration. At the same time, unreasonable processing techniques, such as improper heat treatment processes, can also generate residual stresses within the die, further increasing the risk of stress concentration. For dies with complex structures, the processing difficulty is higher, and stricter requirements are placed on processing accuracy and process control. Any oversight can easily lead to stress concentration issues.

4. Improper Use and Operation

The way dies are used also has a direct impact on their stress concentration status. Improper operation methods, such as overloading the die beyond its designed bearing capacity or subjecting it to frequent impact loads, can cause a sharp increase in internal stress within the die, increasing the likelihood of stress concentration. Moreover, inadequate maintenance and upkeep of the die, such as failing to clean debris from the die surface in a timely manner or not lubricating the die regularly, can accelerate die wear and aging, degrade die performance, and thus trigger stress concentration, shortening the die’s service life.

II. Effective Prevention Strategies for Stress Concentration in Tungsten Carbide Dies

1. Selecting High-Quality Materials with Care

When choosing tungsten carbide materials, a rigorous approach should be adopted, and materials with high quality and few defects should be preferred. For dies with critical components, higher-grade materials can be used, or special heat treatment processes such as quenching and tempering can be applied to enhance the material’s strength and toughness, improving its ability to resist stress concentration. This is akin to forging a sturdy “armor” for the die, enabling it to face stress challenges with greater composure.

2. Optimizing Die Design

The die design stage is crucial for preventing stress concentration. During the design process, the use of excessive sharp corners, abrupt cross-sections, and other structures prone to stress concentration should be avoided as much as possible. For necessary holes and grooves, their shapes and distributions should be carefully designed to be as regular and uniform as possible, reducing the likelihood of stress concentration. At the same time, the stiffness design of the die should be strengthened by reasonably adding stiffening ribs and other structures to improve the die’s ability to resist deformation and ensure a stable stress distribution within the die during use.

3. Enhancing Processing Accuracy and Techniques

The processing quality of the die directly affects its stress concentration situation. During processing, cutting parameters should be strictly controlled, and appropriate feed rates, cutting depths, and cutting speeds should be selected based on the material and structural characteristics of the die to ensure the stability and accuracy of the processing process. At the same time, worn tools should be replaced in a timely manner to maintain tool sharpness and processing accuracy. For dies with complex structures, advanced processing technologies and equipment such as CNC machining centers and electrical discharge machining should be used to improve processing accuracy and efficiency. Additionally, quality inspections and monitoring during the processing process should be strengthened to promptly detect and address potential defects and issues, ensuring that the processing quality of the die meets requirements.

4. Standardizing Use and Conducting Meticulous Maintenance

Correct use and regular maintenance are essential for extending the service life of the die and preventing stress concentration. When using the die, operations should be carried out strictly in accordance with operating procedures, avoiding overloading and frequent impact loads. Operators should receive professional training, be familiar with the performance and operating points of the die, and ensure the standardization and safety of the operation process. At the same time, the die should be regularly inspected and maintained, debris and oil stains on the die surface should be cleaned in a timely manner, and the die should be kept clean and hygienic. Regular lubrication and upkeep of the die should be carried out, and loose fasteners should be checked to promptly detect and address potential faults and issues. For dies that have already shown signs of stress concentration, timely repair or replacement should be carried out to prevent accidents.

5. Strengthening Surface Treatment

Surface treatment of the die is an effective means to reduce the risk of stress concentration. Common surface treatment methods include shot peening and rolling. Shot peening treatment involves using high-speed projectiles to bombard the die surface, causing plastic deformation and forming a compressive stress layer on the surface, thereby improving the die’s fatigue strength and resistance to stress concentration. Rolling treatment uses rolling tools to roll the die surface, causing plastic flow of the surface metal, filling in minor surface defects, improving surface roughness, and forming a compressive stress layer, enhancing the die’s surface performance. These surface treatment methods can effectively improve the stress distribution on the die surface and enhance its resistance to fatigue failure.

6. Eliminating Residual Stresses

Residual stresses generated during the processing and use of the die, when superimposed with external stresses, can exacerbate the stress concentration phenomenon. Therefore, taking effective measures to eliminate residual stresses is crucial. Stress-relief annealing is a commonly used heat treatment process for eliminating residual stresses. By heating the die to an appropriate temperature and holding it for a certain period, followed by slow cooling, the residual stresses within the die are released and eliminated, reducing the risk of stress concentration. In addition, methods such as vibratory stress relief can also be used to eliminate residual stresses and improve the stability and reliability of the die.

III. Conclusion and Outlook

The issue of stress concentration in tungsten carbide dies is a complex and challenging problem in industrial production. However, by thoroughly analyzing its causes and implementing targeted prevention measures, we can effectively reduce the risk of die damage, extend its service life, and improve production efficiency, creating greater economic value for enterprises. In the future course of industrial development, with the continuous emergence of new materials, technologies, and processes, we will face more opportunities and challenges. Continuously exploring and innovating methods and techniques for preventing stress concentration will become an important driving force for promoting industry development. At the same time, we should also strengthen the training and guidance of operators, improving their professional skills and sense of responsibility to ensure the correct use and maintenance of dies. It is believed that with the joint efforts of all parties, tungsten carbide dies will play an even more important role in industrial production and contribute greater strength to promoting industrial progress.