The “Key Strategies” for Quality Inspection of Tungsten Carbide Dies

I. Introduction In the grand landscape of modern manufacturing, tungsten carbide dies shine like bright stars, playing a pivotal role. The quality of these dies is just like a crucial […]

I. Introduction

In the grand landscape of modern manufacturing, tungsten carbide dies shine like bright stars, playing a pivotal role. The quality of these dies is just like a crucial gear in a precision machine, directly determining the precision of products, the speed of production efficiency, and the level of production costs. Therefore, conducting precise quality inspections on tungsten carbide dies has become a key link in ensuring the steady development of the manufacturing industry. Next, this article will delve into how to inspect the quality of tungsten carbide dies from multiple dimensions, including their basic characteristics, the purposes of quality inspection, inspection methods, and inspection procedures.

II. Tungsten Carbide Dies: A Combination of Characteristics and Challenges

Tungsten carbide dies are widely applied in various fields of the manufacturing industry due to their excellent characteristics such as high hardness, high strength, high wear resistance, and high heat resistance. They are like tenacious warriors, able to hold their ground in harsh working environments and provide stable and reliable support for product forming. However, this “warrior” also has its vulnerable sides. Because of their special material properties, tungsten carbide dies are prone to problems such as deformation, cracks, and wear during processing, use, and maintenance. These problems are like hidden “time bombs”. Once they explode, they can have a serious impact on production. Therefore, conducting quality inspections on tungsten carbide dies is not only a comprehensive assessment of their performance but also a precise identification of potential problems, ensuring the stable operation of the dies during production and safeguarding product quality.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

III. Quality Inspection: The “Guardian Angel” of Die Quality

Quality inspection is an important means of ensuring the quality of tungsten carbide dies and shoulders multiple missions:

Accurately Assess Die Performance

Through quality inspection, we can precisely assess key performance indicators of tungsten carbide dies such as hardness, strength, and wear resistance, just as doctors diagnose a patient’s condition. These indicators are like the “health codes” of the dies. Only when they meet the design requirements can the dies perform at their best during production and produce high-quality products.

Timely Discover Potential Problems

There may be some defects and potential problems hidden inside the dies that are difficult to detect with the naked eye, such as cracks and inclusions. These problems are like hidden reefs beneath a calm lake. Once triggered during production, they can lead to die damage, product scrap, and other serious consequences. Quality inspection, on the other hand, is like a pair of “X-ray eyes” that can timely discover these problems, allowing us to take measures for repair or replacement before accidents occur and avoid unnecessary losses.

Significantly Improve Production Efficiency

High-quality tungsten carbide dies are the “secret weapons” for improving production efficiency. They can reduce faults and downtime during the production process, increase the product qualification rate, and thus lower production costs. Through quality inspection, we can ensure that the dies are in the best condition, making the production process smoother and more efficient and creating greater economic benefits for enterprises.

IV. Inspection Methods: A Multi-pronged Approach for Precise Diagnosis

Given the characteristics of tungsten carbide dies, we can adopt multiple inspection methods to conduct a comprehensive and in-depth inspection:

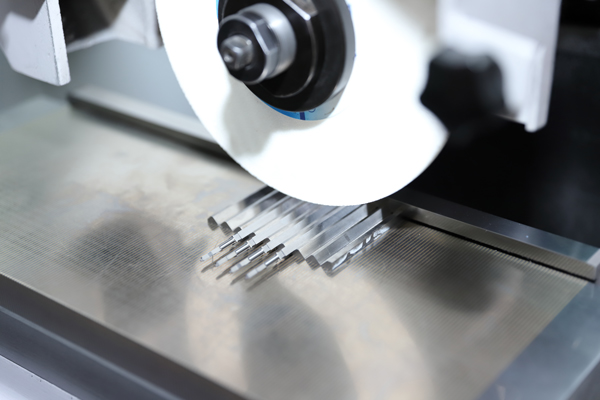

Macroscopic Inspection: A First Glimpse of the Die

First, we use our naked eyes and magnifying glasses to carefully observe the die, just as detectives look for clues at a crime scene, to check for obvious defects on the surface of the die, such as cracks, slag inclusions, and pores. At the same time, we also check whether the geometric shape and dimensions of the die meet the design requirements to ensure that the appearance and dimensional accuracy of the die are up to standard.

Hardness Testing: Measuring the Die’s “Hard Power”

Hardness is one of the important indicators for measuring the performance of tungsten carbide dies. We use advanced equipment such as Rockwell hardness testers and Vickers hardness testers to conduct hardness tests on the dies. During the testing process, we select representative parts for multi-point testing, just as collecting samples from different locations for laboratory tests, to obtain accurate hardness values and comprehensively understand the hardness distribution of the dies.

Strength Testing: Examining the Die’s “Load-bearing Capacity”

Strength testing mainly includes tensile tests and impact tests. These tests are like putting the dies through a “stress test”, allowing us to assess the performance of tungsten carbide dies under external forces. When conducting strength testing, we strictly control the test parameters such as loading speed and test temperature to ensure the accuracy and reliability of the test results and provide a scientific basis for die strength assessment.

Wear Resistance Testing: Simulating Actual Conditions to Evaluate Wear Performance

Wear resistance is an important performance aspect of tungsten carbide dies. We use wear testers to conduct wear resistance tests on the dies, simulating actual working environments and selecting appropriate wear media and wear conditions, just as letting the dies face real “battlefield” tests, to evaluate the wear resistance of the dies and provide a reference for predicting their service life.

Microstructure Analysis: Peering into the Die’s “Inner World”

Through high-precision equipment such as metallurgical microscopes and scanning electron microscopes, we observe and analyze the microstructure of tungsten carbide dies. This is like using a microscope to observe the internal structure of cells, helping us understand the internal structure and defect situations of the dies and providing strong support for quality assessment, revealing the microscopic mysteries behind die performance.

Non-destructive Testing: Detecting Internal Defects without Damaging the Die

Non-destructive testing is a non-destructive inspection method. It is like an “invisible detective” that can detect internal defects in the dies without causing damage. Commonly used non-destructive testing methods include ultrasonic testing and X-ray testing. These methods can detect internal cracks, inclusions, and other defects in the dies, improving the accuracy and reliability of inspection and providing double protection for die quality and safety.

V. Inspection Procedures: Standardized and Orderly to Ensure Quality

To ensure that the quality inspection work of tungsten carbide dies is carried out in an orderly manner, we can follow the following standardized inspection procedures:

Preparation Stage: Sharpening the Axe Will Not Delay the Work of Cutting Wood

Before the inspection begins, we clarify the inspection purposes and requirements, just as soldiers clarify their combat objectives before setting off on a mission. At the same time, we prepare the corresponding inspection equipment and tools and provide training and guidance for the inspection personnel to ensure that they are familiar with the inspection methods and procedures, laying a solid foundation for the smooth conduct of the inspection work.

Macroscopic Inspection: Starting the Inspection Journey

We conduct naked-eye and magnifying glass observations on the tungsten carbide dies to check whether their surfaces and geometric shapes meet the requirements. This is the first step of the inspection work and also an important link for discovering problems.

Hardness Testing: Measuring the Die’s “Hardness Value”

We select appropriate hardness testing methods and conduct multi-point testing on the hardness of the dies to obtain accurate hardness values, providing basic data for die performance assessment.

Strength Testing: Examining the Die’s “Load-bearing Capacity”

According to actual needs, we conduct tensile tests, impact tests, and other strength tests to assess the performance of the dies under external forces and ensure that the dies have sufficient strength.

Wear Resistance Testing: Simulating Actual Conditions to Evaluate Wear Performance

We simulate actual working environments and conduct wear resistance tests on the dies to understand their wear performance during actual use and provide a basis for predicting their service life.

Microstructure Analysis: Peering into the Die’s Internal Structure

We observe and analyze the microstructure of the dies to understand their internal structure and defect situations, providing in-depth information support for quality assessment.

Non-destructive Testing: Detecting Internal Hidden Defects

We use non-destructive testing methods to detect internal defects in the dies, ensuring that there are no hidden cracks, inclusions, and other defects inside the dies and safeguarding their quality and safety.

Result Analysis: Assessing the Die’s Quality Level

Based on the inspection results, we conduct a comprehensive assessment of the quality of the tungsten carbide dies. For dies with problems, we promptly carry out repairs or replacements to ensure that the die quality meets production requirements.

Record-keeping and Reporting: Leaving “Footprints” of the Inspection

We keep detailed records of the inspection process and compile inspection reports. The reports should record information such as inspection results, assessment conclusions, and recommended measures in detail, providing a reference basis for die quality management and subsequent improvements.

Quality inspection is a key link in ensuring the quality of tungsten carbide dies. Through multiple methods such as macroscopic inspection, hardness testing, strength testing, wear resistance testing, microstructure analysis, and non-destructive testing, combined with standardized inspection procedures and operation methods, we can comprehensively and accurately assess the performance and quality of tungsten carbide dies. Through effective quality inspection, we can timely discover and solve problems in tungsten carbide dies, improve their stability and service life, and provide strong support for the development of the manufacturing industry, helping the manufacturing industry move forward steadily on the path of high-quality development.