High – Speed Steel vs. Tungsten Carbide

I. Introduction In high – end manufacturing fields such as metal cutting, mold manufacturing, and aerospace, high – speed steel (HSS) and tungsten carbide are like two shining stars, each […]

I. Introducción

In high – end manufacturing fields such as metal cutting, mold manufacturing, and aerospace, high – speed steel (HSS) and tungsten carbide are like two shining stars, each emitting its unique brilliance and playing an indispensable role. However, the debate over which of the two is superior has never ceased. This article will conduct a comprehensive and in – depth analysis and comparison of high – speed steel and tungsten carbide from multiple dimensions, including material composition, performance characteristics, application scenarios, and development trends, aiming to provide readers with a clear and accurate answer.

II. Composition and Performance of High – Speed Steel and Tungsten Carbide

High – Speed Steel: The Evergreen in the Cutting Field

High – speed steel (HSS) can be regarded as an “all – round player” among tool steels. It combines high hardness, high wear resistance, and high heat resistance. Its composition is extremely complex, containing various carbide – forming elements such as tungsten, molybdenum, chromium, vanadium, and cobalt, with the total amount of alloy elements ranging from approximately 10% to 25%. The most prominent feature of high – speed steel is its red hardness. Even in the high – temperature environment (around 500℃) generated during high – speed cutting, it can still maintain a relatively high hardness, with an HRC value exceeding 60. This characteristic enables it to maintain a high cutting efficiency and have a long service life during the cutting process.

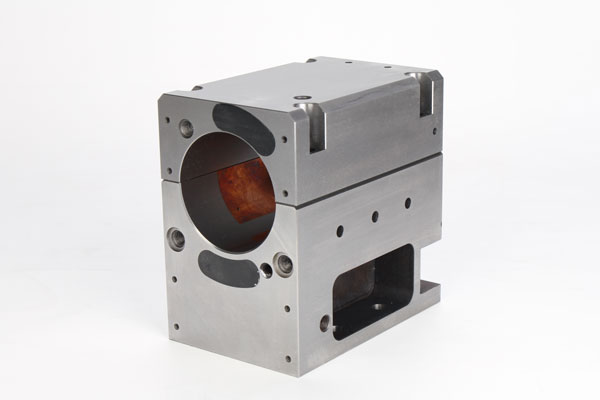

Nuestra actividad de fábrica: piezas de carburo, piezas de molde, moldes de inyección médica, moldes de inyección de precisión, moldeo por inyección de teflón PFA, accesorios de tubo PFA. correo electrónico: [email protected],whatsapp:+8613302615729.

High – speed steel has a wide range of applications in the manufacturing field. It is mainly used to manufacture complex thin – edged and impact – resistant metal cutting tools, such as turning tools, drills, and hobs, which are all its “masterpieces”. In addition, it can also be used to manufacture high – temperature bearings and cold – extrusion molds. High – speed steel has good processability, and its strength and toughness are well – balanced, allowing it to easily cope with the use requirements under various complex working conditions.

Tungsten Carbide: The Hardcore Powerhouse in High – End Manufacturing

Tungsten carbide is an alloy steel containing a high proportion of tungsten elements. Usually, the tungsten content ranges from 3% to 18%, and it also incorporates other elements such as nickel, molybdenum, chromium, and cobalt. Tungsten carbide possesses a series of remarkable excellent properties, including high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance. In particular, its high hardness and wear resistance remain almost unchanged even at 500℃, and it still maintains a relatively high hardness at 1000℃. This makes tungsten carbide shine brightly in high – end manufacturing fields such as aerospace engines, automotive parts, tools, and electronic devices.

The main components of tungsten carbide are tungsten carbide and cobalt, accounting for 99% of the total, with the remaining 1% being other metals. Tungsten carbide belongs to a sintered composite material containing at least one metal carbide. The grain size of the carbide component (or phase) is usually in the range of 0.2 – 10 microns, and the carbide grains are tightly bonded together by metal binders. This unique structure endows tungsten carbide with excellent comprehensive performance.

III. Application Comparison of High – Speed Steel and Tungsten Carbide

Application Fields: Stages Where Each Shows Its Strengths

High – speed steel is mainly active in fields such as metal cutting tools and mold manufacturing. Its outstanding red hardness enables it to maintain high hardness and wear resistance during high – speed cutting, making it a “right – hand man” in these fields. On the other hand, tungsten carbide occupies an important position in high – end fields such as aerospace engines, automotive parts, tools, and electronic devices. Its high hardness and wear resistance can perfectly meet the strict requirements for material performance in these fields.

Performance Characteristics: Each Has Its Own Unique Advantages

High – speed steel and tungsten carbide have their own advantages and disadvantages in terms of performance. High – speed steel stands out with its relatively high red hardness and good processability, enabling it to handle various complex working conditions with ease. Tungsten carbide, on the other hand, is renowned for its even higher hardness and wear resistance, and can maintain stable performance under extreme conditions. In addition, tungsten carbide also has good corrosion resistance and electrical conductivity, allowing it to showcase its capabilities in more special environments.

IV. Development Trends and Future Prospects

High – Speed Steel: Moving Towards Higher Performance

With the vigorous development of the manufacturing industry, the performance requirements for high – speed steel are also increasing. In the future, high – speed steel will continue to evolve towards higher hardness, higher wear resistance, better heat resistance, and better processability. At the same time, with the increasing maturity of powder metallurgy technology, powder metallurgy high – speed steel will gradually replace traditional high – speed steel and become the preferred material in high – end manufacturing.

Tungsten Carbide: Expanding the Application Territory in High – End Fields

As a high – performance alloy material, tungsten carbide will undoubtedly continue to hold the top position in high – end manufacturing in the future. With the continuous emergence of new materials and new technologies, the performance of tungsten carbide will be further improved. Its application fields will also continue to expand, especially in fields such as aerospace and new energy, where the application of tungsten carbide will be more extensive, injecting strong impetus into the development of these fields.

V. Conclusión

In conclusion, high – speed steel and tungsten carbide are like two “martial arts masters” with their own unique skills, each possessing distinct performance advantages and application fields. In fields such as metal cutting and mold manufacturing, high – speed steel becomes an indispensable important material due to its high hardness, high wear resistance, and good processability. In high – end manufacturing, tungsten carbide stands out as a “star material” with its even higher hardness and wear resistance, good corrosion resistance, and electrical conductivity. Therefore, we cannot simply judge which material is better. Instead, we should choose the most suitable material according to specific application requirements.