The Impact of Microstructure on the Performance of Tungsten Carbide Die

In the field of modern industrial manufacturing, tungsten carbide die serves as a crucial tool. Its performance directly determines the quality of products and the efficiency of production. The microstructure […]

In the field of modern industrial manufacturing, tungsten carbide die serves as a crucial tool. Its performance directly determines the quality of products and the efficiency of production. The microstructure of the die, as the foundation of its internal structure, plays a decisive role in its performance. This article will delve into how the microstructure of tungsten carbide die affects its overall performance and explore effective ways to optimize the microstructure to enhance the die’s performance.

I. Basic Composition of the Microstructure of Tungsten Carbide Die

Tungsten carbide, also known as hard alloy, is manufactured through powder metallurgy methods using tungsten carbide and other metal carbides such as cobalt carbide and titanium carbide. The size, shape, and distribution of these carbide particles constitute the microstructure of the tungsten carbide die. Factors such as the size of carbide particles, the distribution of phases, and the characteristics of grain boundaries in the microstructure all have a significant impact on the die’s performance. For example, different sizes of carbide particles interacting with each other in the die can change its stress situation, thereby affecting its overall performance.

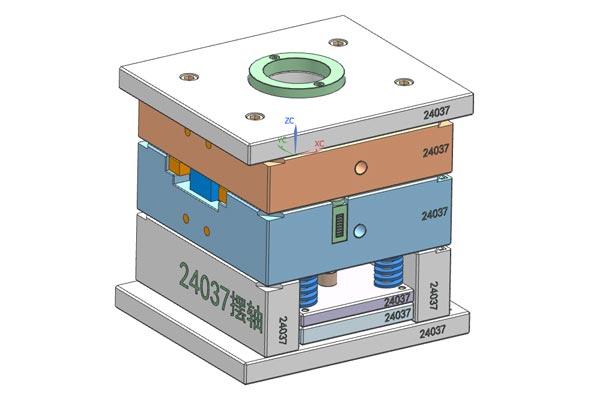

Nuestra actividad de fábrica: piezas de carburo, piezas de molde, moldes de inyección médica, moldes de inyección de precisión, moldeo por inyección de teflón PFA, accesorios de tubo PFA. correo electrónico: [email protected],whatsapp:+8613302615729.

II. The Impact of Microstructure on the Performance of Tungsten Carbide Die

1. Hardness and Wear Resistance

The hardness and wear resistance of tungsten carbide die mainly depend on the size and distribution of carbide particles. Fine carbide particles, like numerous tiny “hard cornerstones,” can provide the die with higher hardness and better wear resistance. When carbide particles are fine and uniformly distributed, the surface hardness of the die is significantly increased, acting as a sturdy “armor” that effectively resists wear and indentation, thus greatly extending the die’s service life. In actual production, using dies with such a microstructure can reduce the frequency of die replacement and lower production costs.

2. Strength and Toughness

The strength and toughness of the die are closely related to the content and distribution of the metal binder phase in its microstructure. An appropriate amount of metal binder phase, such as cobalt, is like injecting a “toughening force” into the die, which can improve its toughness and prevent brittle fracture during use. At the same time, the metal binder phase can also act like “glue,” enhancing the bonding force between carbide particles and increasing the overall strength of the die. For example, when subjected to large impact forces, a die with a good distribution of metal binder phase can better disperse stress and avoid local damage.

3. Heat Resistance

The performance of tungsten carbide die in high-temperature environments is also influenced by its microstructure. Fine carbide particles and a uniform distribution of the metal binder phase contribute to improving the die’s heat resistance. This microstructure is like a stable “thermal protection net” that can reduce the generation of thermal cracks, enhance the stability of the die at high temperatures, and thus extend its service life. In high-temperature processing scenarios, dies with good heat resistance can work continuously and stably, ensuring production efficiency.

4. Corrosion Resistance

The corrosion resistance of tungsten carbide die is closely related to the density and uniformity of its microstructure. A dense microstructure is like a tight “protective shield” that can effectively reduce the penetration of corrosive media and improve the die’s corrosion resistance. In addition, the selection and content of the metal binder phase also affect the die’s corrosion resistance. For example, certain specific metal binder phases can form a protective film to prevent corrosive media from contacting the die matrix.

III. Methods for Optimizing the Microstructure of Tungsten Carbide Die

1. Optimization of Powder Metallurgy Process

By optimizing process parameters in powder metallurgy, such as sintering temperature, pressure, and time, the size and distribution of carbide particles can be precisely controlled, thereby optimizing the die’s microstructure. Reasonable process parameters are like a skilled “sculptor” that can make carbide particles finer and more uniformly distributed,全面提升 (comprehensively improving) the overall performance of the die. For example, appropriately increasing the sintering temperature and extending the holding time can enable carbide particles to fully diffuse and achieve a more uniform distribution.

2. Selection and Addition of Alloying Elements

Adding appropriate amounts of alloying elements, such as nickel and chromium, can improve the microstructure of tungsten carbide die. These alloying elements are like magical “additives” that can form more stable compounds with carbide particles and the metal binder phase, enhancing the hardness, toughness, and corrosion resistance of the die. For example, adding nickel elements can increase the toughness and corrosion resistance of the die, enabling it to maintain good performance under complex working conditions.

3. Application of Heat Treatment Process

Heat treatment processes, such as quenching and tempering, can further adjust the microstructure of tungsten carbide die. A reasonable heat treatment process is like a “plastic surgeon” that can change the shape and distribution of carbide particles, eliminate internal stress, and improve the performance and stability of the die. For example, quenching treatment can endow the die with high hardness and strength, while tempering treatment can eliminate quenching stress and improve the die’s toughness.

IV. Conclusión

The microstructure of tungsten carbide die has a significant and multifaceted impact on its performance. By optimizing the powder metallurgy process, reasonably selecting and adding alloying elements, and applying heat treatment processes, the microstructure of the die can be effectively improved, thereby enhancing its hardness, wear resistance, strength, toughness, heat resistance, and corrosion resistance. These optimization measures help increase the service life and production efficiency of tungsten carbide die, providing higher-quality products and services for modern industrial manufacturing.

In future research and practical applications, we should continuously explore and innovate methods and technologies for optimizing the microstructure of tungsten carbide die. By constantly improving and refining relevant processes and technical means, we can further enhance the performance and quality of tungsten carbide die to meet the stringent requirements of modern industrial manufacturing for high precision, high efficiency, and high stability. At the same time, it is also crucial to strengthen the training and guidance of operators to ensure that they can correctly understand and apply these optimization measures and fully unleash the performance advantages of tungsten carbide die, driving industrial manufacturing to a higher level.