Analysis of Common Faults and Countermeasures of Tungsten Carbide Die

In the context of the booming manufacturing industry, tungsten carbide die has become an indispensable key tool in numerous production processes due to its high strength, high hardness, and excellent […]

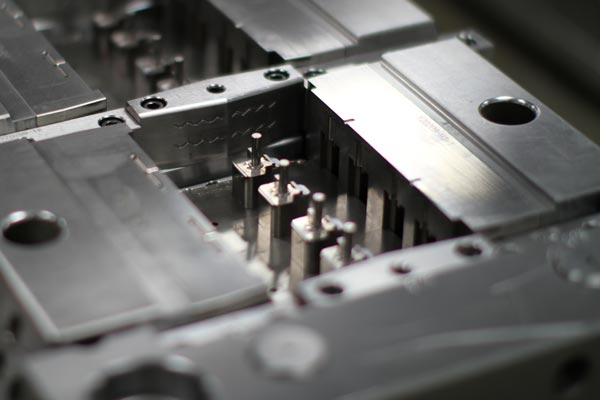

In the context of the booming manufacturing industry, tungsten carbide die has become an indispensable key tool in numerous production processes due to its high strength, high hardness, and excellent wear resistance, widely applied in the molding manufacturing of various products. However, even with its outstanding performance, tungsten carbide die is still prone to various faults during long-term high-intensity and high-load use. These faults not only affect production progress and product quality but may also increase production costs. This article will comprehensively and in-depth explore the common faults of tungsten carbide die and elaborate on targeted countermeasures, while proposing effective preventive measures to help manufacturers and users better maintain tungsten carbide die, enhance production efficiency, and extend the service life of the die.

I. Types of Common Faults in Tungsten Carbide Die

1. Wear and Tear

Wear and tear is the most common fault of tungsten carbide die. During continuous use, the die surface constantly rubs against the material, especially under high-load working conditions, where wear becomes more pronounced. Minor wear may only affect the surface finish of the die, but as the degree of wear increases, the precision of the die will significantly decline. This leads to increased dimensional deviations in the produced products, uneven product quality, and a reduction in production efficiency.

Notre activité : pièces en carbure, pièces de moule, moules d'injection médicale, moules d'injection de précision, moulage par injection de téflon PFA, raccords de tubes PFA. email : [email protected],whatsapp:+8613302615729.

2. Cracks and Fractures

Tungsten carbide die often has to withstand enormous pressure and strong impact forces during work, making cracks and fractures another common and serious fault. Stress concentration is a major factor contributing to cracks and fractures. When the die structure is unreasonable, such as having sharp corners or uneven thickness, local stress concentration is likely to occur. In addition, material fatigue and improper operation, such as overloading or rapid heating and cooling, can also cause cracks in the die and even lead to fractures, posing significant safety hazards and economic losses to production.

3. Deformation

In high-temperature and high-pressure adverse working environments, the probability of deformation in tungsten carbide die increases significantly. Thermal deformation is the main form of die deformation. When the die cannot be effectively cooled during work and its temperature continues to rise, the internal stress distribution within the material changes, resulting in a change in the die’s shape. After deformation, the precision of the die is severely reduced, and it may not be able to properly cooperate with the equipment or even complete the product molding process, seriously affecting normal production.

4. Die Sticking

Die sticking refers to the adhesion between the die and the product, preventing the product from being smoothly ejected from the die. This problem not only reduces production efficiency and increases production cycles but may also damage the die surface or the product during the ejection process, causing unnecessary losses. Die sticking is usually closely related to factors such as the surface quality of the die, the ejection design, and process parameters.

5. Corrosion

In certain specific working environments, such as humid air or places containing corrosive media, tungsten carbide die is prone to corrosion. Corrosion gradually erodes the surface and internal structure of the die, weakening its strength and hardness and reducing its service life. A die that has been corroded for a long time will experience a significant decline in performance and may even be unable to meet normal production requirements.

II. Precise Countermeasures for Fault Elimination

1. Strategies for Dealing with Wear and Tear

- Inspection et entretien réguliers: Establish a comprehensive die inspection system and regularly conduct thorough inspections of the die to promptly detect signs of wear. Once wear is detected, take corresponding repair measures according to the degree of wear, such as grinding or welding repair. If the wear is severe, replace the die in a timely manner to ensure normal production.

- Optimize the Lubrication System: Good lubrication is the key to reducing die wear. Ensure that there is sufficient and appropriate lubricant during the die’s working process, which can effectively reduce the friction between the die and the material and minimize wear. At the same time, regularly check and replace the lubricant to ensure the normal operation of the lubrication system.

- Apply Wear-Resistant Coatings: Coating a layer of wear-resistant coating on the die surface, such as carbide or nitride coatings, can significantly improve the wear resistance of the die. These coatings have high hardness, excellent wear resistance, and good chemical stability, which can effectively resist the wear and corrosion of the material and extend the service life of the die.

2. Prevention and Treatment Measures for Cracks and Fractures

- Optimize Die Design: By improving the structural design of the die, avoid areas of stress concentration. For example, change sharp corners to rounded transitions and reasonably adjust the uniformity of the die’s thickness to reduce the risk of cracks and fractures from the source.

- Optimize Heat Treatment Process: A reasonable heat treatment process can improve the toughness and fatigue resistance of the die. According to the material and usage requirements of the die, select appropriate heat treatment methods and process parameters, such as quenching temperature and tempering time, to enable the die to obtain good comprehensive mechanical properties.

- Regular Non-Destructive Testing: Use non-destructive testing techniques, such as ultrasonic testing and magnetic particle testing, to regularly conduct comprehensive inspections of the die’s interior and promptly detect potential cracks. Once cracks are found, take corresponding repair measures according to the size and location of the cracks, such as welding or grinding, to prevent the cracks from further expanding and causing fractures.

3. Correction Methods for Deformation

- Strengthen the Cooling System: Ensuring that the die can be effectively cooled during work is the key to preventing thermal deformation. Optimize the design of the die’s cooling system, increase the number and flow rate of cooling water channels, and improve the cooling efficiency to keep the die at a relatively stable temperature during work and reduce the occurrence of thermal deformation.

- Optimize Material Selection: Select materials with better thermal stability to manufacture the die, which can improve the die’s resistance to deformation in high-temperature environments. For example, some new types of tungsten carbide materials have higher thermal hardness and thermal stability and can maintain good dimensional accuracy and mechanical properties at high temperatures.

- Regular Die Calibration: Regularly calibrate the die, check its dimensional accuracy and shape tolerances, and promptly detect and correct die deformation. Through professional calibration equipment and processes, restore the die to its original precision requirements to ensure stable product quality.

4. Solutions for Die Sticking

- Optimize Ejection Design: Improve the ejection structure of the die to make it easier for the product to be ejected. For example, reasonably design the ejection draft angle and increase the ejection mechanism to reduce the adhesion between the product and the die and enable smooth ejection.

- Use Release Agents: Applying an appropriate amount of release agent between the die and the product can effectively reduce the adhesion between the two. Select appropriate release agents and adjust them according to the material of the product and the production process to ensure that the release agent can achieve the best release effect.

- Control Process Parameters: Optimizing process parameters such as injection pressure, injection speed, and holding pressure in injection molding or die-casting can reduce the occurrence of die sticking. By setting reasonable process parameters, the product can evenly fill the die cavity during the molding process, avoiding situations of local overpressure or underpressure and thus reducing the risk of die sticking.

5. Corrosion Protection Measures

- Select Corrosion-Resistant Materials: When manufacturing the die, select more corrosion-resistant materials according to the requirements of the working environment. For example, some tungsten carbide materials containing special alloy elements have better corrosion resistance and can be used for a long time in harsh environments without being corroded.

- Surface Anti-Corrosion Treatment: Conduct anti-corrosion treatment on the die surface, such as zinc plating, chromium plating, or spraying anti-corrosion coatings, to form a protective film that prevents corrosive media from coming into contact with the die surface and thus plays an anti-corrosion role. Select appropriate surface treatment methods according to different working environments and usage requirements.

- Control the Working Environment: Try to control the humidity and the content of corrosive media in the working environment to create a good working environment for the die. For example, install dehumidification equipment in humid environments to reduce the moisture in the air; for workplaces containing corrosive media, take ventilation and sealing measures to reduce the impact of corrosive media on the die.

III. Preventive Measures and Suggestions for Precaution

1. Training for Operators

Regularly organize professional training for operators to familiarize them with the correct usage methods and maintenance procedures of the die. The training content includes die installation, debugging, operation precautions, and daily maintenance, improving the operators’ skill levels and sense of responsibility and reducing die faults caused by improper operation.

2. Establish a Strict Maintenance System

Formulate and implement a strict die inspection and maintenance plan, clarifying the maintenance cycle, content, and responsible persons. Regularly conduct comprehensive inspections of the die, including appearance inspection, dimensional measurement, and performance testing, promptly detect potential problems, and take corresponding measures for treatment. At the same time, establish a die maintenance file to record the usage and maintenance history of the die, providing a reference for die management and repair.

3. Select High-Quality Materials and Coatings

In the die manufacturing process, select high-quality tungsten carbide materials and wear-resistant coatings to ensure that the die has good performance and service life. Cooperate with reputable suppliers, strictly control the quality of materials and coatings, and conduct necessary testing and experiments to ensure that they meet relevant standards and requirements.

4. Monitor Process Parameters

Closely monitor changes in process parameters such as temperature, pressure, and speed in injection molding or die-casting to ensure that they are in the optimal state. Install corresponding monitoring equipment to monitor process parameters in real-time and adjust them in a timely manner. By optimizing process parameters, improve the molding quality of products and reduce the fault rate of the die.

5. Backup Key Dies

To cope with sudden faults, it is recommended to back up key dies. When the die in use has a serious fault and cannot be repaired in a timely manner, the backup die can be immediately put into use, reducing the risk of production interruption and ensuring the continuity and stability of production.

IV. Conclusion

Tungsten carbide die, as an important support in the manufacturing industry, plays a decisive role in production efficiency and product quality. By having an in-depth understanding of the common faults of tungsten carbide die, mastering precise countermeasures, and taking effective preventive measures, manufacturers and users can better prevent and maintain the die, reduce the fault rate, improve production efficiency, and lower costs. This not only helps to enhance the economic benefits and market competitiveness of enterprises but also lays a solid foundation for the sustainable and healthy development of the manufacturing industry. In future production practices, we should continuously summarize experience, continuously improve die design, manufacturing, and maintenance technologies, and promote tungsten carbide die towards higher performance and longer service life.

Articles connexes

- How to Comprehensively Ensure the Stability of Tungsten Carbide Dies under High Loads

- Selection Basis for Wear-Resistant Coating Materials of Tungsten Carbide Die

- How to Enhance the Performance of Tungsten Carbide Die through Heat Treatment

- Enhancing the Performance of Tungsten Carbide Die through Advanced Manufacturing Technologies