Protection Strategies for Tungsten Carbide Dies in High-Temperature and High-Humidity Environments

In industrial production, tungsten carbide dies play a crucial role due to their high hardness, high strength, and excellent wear resistance. However, when exposed to high-temperature and high-humidity environments, they […]

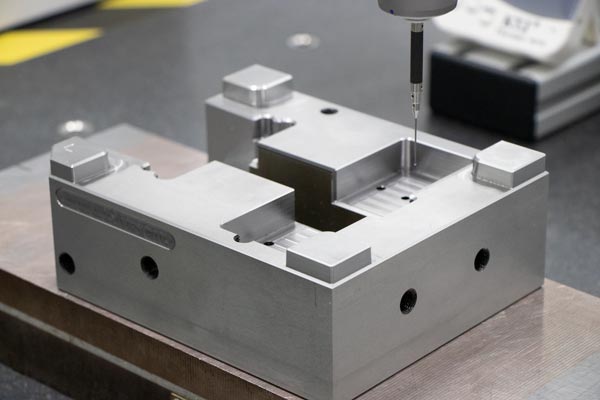

In industrial production, tungsten carbide dies play a crucial role due to their high hardness, high strength, and excellent wear resistance. However, when exposed to high-temperature and high-humidity environments, they are highly susceptible to oxidation and corrosion, which can impact their performance and service life. To effectively address this issue, a series of protective measures can be taken as follows.

I. Select Premium Packaging Materials to Fortify Transportation and Storage

The selection of packaging materials is the first line of defense in protecting tungsten carbide dies. It is advisable to choose packaging materials with moisture-proof and waterproof properties, such as moisture-proof paper and moisture-proof cloth. These materials can construct a solid barrier during transportation and storage, effectively blocking the invasion of humid air and ensuring that the dies remain dry. Meanwhile, priority should be given to eco-friendly materials that are degradable or recyclable. This not only protects the dies but also aligns with the concept of green development, reducing the negative impact on the environment.

Notre activité : pièces en carbure, pièces de moule, moules d'injection médicale, moules d'injection de précision, moulage par injection de téflon PFA, raccords de tubes PFA. email : [email protected],whatsapp:+8613302615729.

II. Strengthen Protective Coatings to Isolate External Corrosion

Applying anti-rust agents or protective films on the surface of tungsten carbide dies is a key measure to prevent oxidation. This operation forms a dense isolation layer on the die surface, separating the air’s moisture and oxygen from the die surface, thereby fundamentally reducing the likelihood of oxidation and corrosion. However, protective coatings are not a one-time solution. Regular inspections and reapplications are necessary. Once any damage or peeling of the coating is detected, timely repairs should be carried out to ensure that the protective effect remains effective.

III. Improve Storage Conditions to Create a Dry Environment

The storage environment directly affects the quality of tungsten carbide dies. It is essential to select a dry and well-ventilated location for storing the dies, avoiding long-term exposure to humid environments. Humid air can accelerate the oxidation and corrosion process of the dies, while a dry and ventilated environment can effectively suppress this phenomenon. Additionally, desiccants can be placed in the storage area or dehumidification equipment can be used to further reduce the environmental humidity, creating an ideal storage condition for the dies.

IV. Optimize Process Flows to Minimize Environmental Exposure

The rational arrangement of process flows is crucial for the protection of tungsten carbide dies. It is advisable to minimize prolonged operation and exposure of the dies in high-temperature and high-humidity environments. For processes that must be carried out in such environments, practical cooling and dehumidification measures should be implemented. For example, water-cooling systems can be used to cool the dies, reducing their temperature. Air conditioners or dehumidifiers can be installed to adjust the environmental temperature and humidity, providing a relatively suitable working environment for the dies.

V. Enhance Equipment Maintenance to Ensure Normal Operation

The operating status of die processing equipment directly impacts the quality of tungsten carbide dies. Regular inspections and maintenance of the equipment are necessary to ensure its normal operation and good heat dissipation performance. If the equipment malfunctions or has poor heat dissipation, it may cause local overheating of the dies, accelerating oxidation and corrosion. At the same time, equipment and tools that come into direct contact with the dies should be kept clean and dry. Moisture and impurities may adhere to the die surface and cause damage, so strict cleaning and drying measures must be taken.

VI. Strengthen Staff Training to Elevate Protection Awareness

Employees are the direct executors of the protection work for tungsten carbide dies, and their protection awareness and skill level are of utmost importance. It is necessary to raise employees’ awareness of the protection knowledge of tungsten carbide dies, enabling them to fully understand the hazards of high-temperature and high-humidity environments to the dies and the importance of protection work, thereby enhancing their emphasis on die protection. In addition, regular protection skill training should be provided to employees to ensure that they can master the methods and techniques of die protection proficiently and carry out protection operations correctly and effectively in practical work.

VII. Establish a Detection and Evaluation Mechanism for Timely and Precise Protection

Establishing a regular detection and evaluation mechanism is an important guarantee for ensuring the stable and reliable operation of tungsten carbide dies in high-temperature and high-humidity environments. Regular surface detection and evaluation of the dies can promptly detect problems such as rust and corrosion on the die surface. Once problems are identified, targeted protective measures should be taken promptly based on the detection and evaluation results, such as derusting the rusted areas and reapplying protective coatings, to ensure that the dies are always in good working condition.

By implementing the above comprehensive and systematic protective measures, the oxidation and corrosion risks of tungsten carbide dies in high-temperature and high-humidity environments can be effectively reduced, significantly extending their service life and thereby improving production efficiency and creating greater economic benefits for enterprises.