Best Practices for Cleaning and Maintenance of Tungsten Carbide Dies

In the grand landscape of industrial production, tungsten carbide dies serve as precise cornerstones. Their accuracy and durability are akin to the core components of sophisticated instruments, directly and profoundly […]

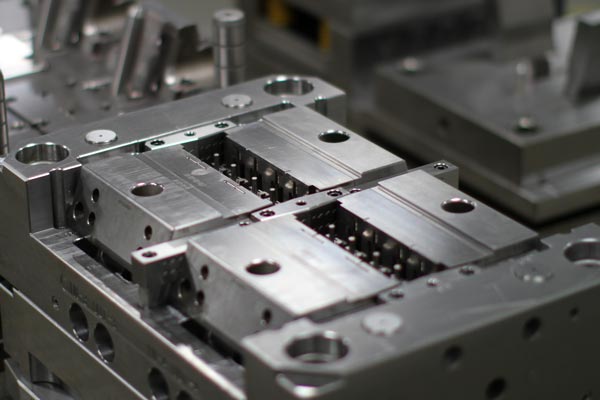

In the grand landscape of industrial production, tungsten carbide dies serve as precise cornerstones. Their accuracy and durability are akin to the core components of sophisticated instruments, directly and profoundly influencing product quality and production efficiency. Once issues arise with the dies, it is similar to a sophisticated instrument malfunctioning, which will not only lead to a decline in product quality but also cause production halts, resulting in significant economic losses. Therefore, conducting scientific and meticulous cleaning and maintenance on the dies is of utmost importance to ensure their long-term stable and efficient operation and minimize the occurrence of faults and downtime. This article will delve into the best practices for cleaning and maintaining tungsten carbide dies, providing factories and enterprises with a comprehensive and practical guide for die management and upkeep.

I. Precise Cleaning: Nurturing the Clean Foundation of Dies

(A) Selecting Appropriate Cleaning Agents

The choice of cleaning agents when cleaning tungsten carbide dies is a crucial step. It is advisable to opt for cleaning agents specifically designed for metal dies. These cleaning agents act like dedicated “cleaning guardians” for the dies, possessing powerful cleaning capabilities to effectively remove oil stains, metal shavings, and various stubborn contaminants. At the same time, they have a gentle “nature” and will not cause corrosion or damage to the die surface, just like a gentle caretaker carefully protecting every inch of the die’s surface. On the contrary, strongly acidic or alkaline cleaning agents are like fierce “destroyers” that will mercilessly damage the protective layer on the die surface, so they must be strictly avoided.

O nosso negócio de fábrica: peças de metal duro, peças de molde, moldes de injeção médica, moldes de injeção de precisão, moldagem por injeção de teflon PFA, acessórios para tubos PFA. e-mail: [email protected],whatsapp:+8613302615729.

(B) Establishing a Reasonable Cleaning Schedule

Formulating a scientific and reasonable cleaning schedule is a crucial step in ensuring the cleanliness of the dies. It is recommended to carry out a basic cleaning after each use of the die, similar to giving the die a daily “cleaning care” to promptly remove surface residues and dirt and prevent them from accumulating on the die surface. In addition, a regular in-depth cleaning plan should be formulated based on the die’s usage frequency and working environment, akin to giving the die a comprehensive “deep-cleaning spa” to thoroughly remove dirt and accumulated impurities inside the die, keeping the die always fresh and clean.

(C) Mastering Correct Cleaning Methods

The cleaning method is of great significance during the cleaning process. Avoid using sharp tools or hard objects to directly scrape the die surface, as these “rough elements” can easily leave scratches or cause damage to the die surface, just like leaving flaws on a delicate porcelain piece. Instead, use a soft-bristled brush or sponge to gently wipe the die surface, like a gentle touch, ensuring that the cleaning agent evenly covers and penetrates into every corner of the die. After cleaning, rinse thoroughly with clean water and carefully dry the die with a clean cloth to make it look brand new.

II. Meticulous Maintenance: Prolonging the Excellent Performance of Dies

(A) Lubrication and Rust Prevention Go Hand in Hand

After cleaning, the die, like freshly bathed skin, requires timely care. At this time, it is necessary to promptly apply a special anti-rust oil or lubricant to the die, dressing it in a “protective coat” to prevent the die from rusting or sticking. The selection of lubricants should be based on the die’s working environment and requirements, just like choosing the right skincare product for different skin types, ensuring that the lubricant is compatible with the die material and provides sufficient lubrication. Meanwhile, regularly inspect and replenish the lubricant to keep the die in a well-lubricated state at all times, similar to adding lubricating oil to a machine regularly to ensure its smooth operation.

(B) Proper Storage for Peace of Mind

The cleaned and lubricated die needs a safe and comfortable “home” for storage. Avoid exposing the die to direct sunlight and humid environments, as sunlight and moisture are like “invisible killers” for the die, accelerating its aging and damage. It is recommended to place the die in a dry and well-ventilated warehouse and support and fix it with a special die rack, allowing the die to settle down steadily. In addition, regularly inspect and turn over the stored dies to prevent deformation or damage caused by prolonged pressure, just like turning over a sleeping object regularly to maintain its good condition.

(C) Regular Inspection and Maintenance with Meticulous Attention

In addition to daily cleaning and lubrication, regular comprehensive inspection and maintenance of the die are also essential. This is similar to having a regular physical examination for the body, enabling the timely discovery of potential problems. The inspection content includes the die’s surface condition, dimensional accuracy, and fit clearance. If wear, cracks, or other defects are found on the die, repair or replacement should be carried out promptly, just like treating an ill body on time to prevent the condition from worsening. At the same time, the maintenance plan should be flexibly adjusted according to the die’s usage situation to ensure that the die is always in the best working condition, similar to adjusting clothing according to different seasons to adapt to environmental changes.

III. Other Key Points: Comprehensively Ensuring the Effectiveness of Cleaning and Maintenance

(A) Safety Operations as the Top Priority

Safety always comes first during the cleaning and maintenance process. Strictly adhere to safety operation procedures, just like obeying traffic rules, to ensure that every operation step is safe and reliable. When using cleaning agents, wear protective gloves and goggles to prevent direct contact between the cleaning agent and the skin or eyes, like putting on protective gear for the body to avoid injury. Meanwhile, maintain good ventilation in the workplace to prevent harmful gases generated by the volatilization of cleaning agents from causing harm to the human body, similar to installing an “air purifier” in the workplace to create a safe and healthy working environment.

(B) Record Management for Traceability

Establishing a complete record system for die cleaning and maintenance is an important guarantee for ensuring the long-term stable operation of the die. After each cleaning and maintenance, detailed records should be made of the cleaning time, type of cleaning agent, type and quantity of lubricant, etc., like creating a detailed “health record” for the die. These records not only help in timely discovery of problems during the die’s usage but also provide important references for subsequent maintenance and replacement, similar to doctors using medical records to understand a patient’s medical history and formulate more precise treatment plans.

(C) Training and Guidance to Enhance Skills

To ensure the effectiveness of the cleaning and maintenance work, regular training and guidance should be provided to the operators. The training content should cover knowledge such as the selection and use of cleaning agents, the application method of lubricants, and the storage and preservation of dies, like providing operators with a comprehensive “operation manual”. Through training, improve the operators’ professional skills and sense of responsibility, enabling them to correctly carry out cleaning and maintenance tasks, similar to conducting strict training for soldiers to improve their combat effectiveness and execution ability.

IV. Conclusion: Looking Forward to the Future and Continuous Innovation

The cleaning and maintenance work of tungsten carbide dies is a systematic and meticulous project, which is of irreplaceable importance for ensuring the accuracy and durability of the dies. By applying best practices such as selecting appropriate cleaning agents, formulating reasonable cleaning schedules, mastering correct cleaning methods, carrying out lubrication and rust prevention work, storing the dies properly, conducting regular inspection and maintenance, and paying attention to safety operations, record management, and training and guidance, we can effectively prolong the service life of the dies, improve production efficiency and product quality, and create greater economic value for factories and enterprises.

In future industrial production, with the continuous emergence of new materials and technologies, the cleaning and maintenance work of tungsten carbide dies will face more challenges and opportunities. Therefore, we need to continuously explore and innovate cleaning and maintenance methods, improve the maintenance level and management efficiency of dies, like exploring new navigation channels in the ocean of technology to lead the industry to a higher level. By implementing the above best practices and continuously improving and optimizing them according to actual situations, we are confident in creating a more brilliant future for factories and enterprises and making greater contributions to social development.