How to Accurately Select a Suitable Tungsten Carbide Die Based on Processing Requirements

In the grand landscape of modern industrial production, dies serve as the cornerstone of precision manufacturing. The quality and performance of dies directly determine the final quality of products and […]

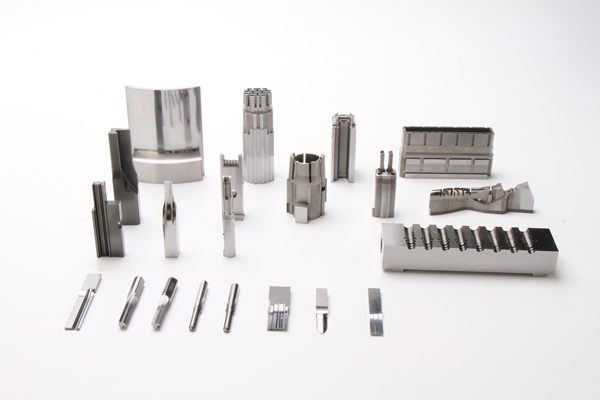

In the grand landscape of modern industrial production, dies serve as the cornerstone of precision manufacturing. The quality and performance of dies directly determine the final quality of products and the efficiency of production. Tungsten carbide dies, with their remarkable characteristics such as high hardness, excellent wear resistance, outstanding corrosion resistance, and good thermal stability, shine brightly in the field of die manufacturing and occupy a pivotal position. However, faced with a wide array of tungsten carbide die types and specifications on the market, how to precisely select a suitable die according to processing requirements has become a critical issue for many enterprises. This article will comprehensively explore how to choose the right tungsten carbide die based on processing requirements from multiple dimensions, including an in-depth analysis of processing requirements, the diverse types and characteristics of tungsten carbide dies, scientific selection methods, and key considerations.

I. In-Depth Analysis of Processing Requirements

Before selecting a tungsten carbide die, it is crucial to conduct a comprehensive and in-depth analysis of processing requirements. This mainly encompasses the following aspects:

O nosso negócio de fábrica: peças de metal duro, peças de molde, moldes de injeção médica, moldes de injeção de precisão, moldagem por injeção de teflon PFA, acessórios para tubos PFA. e-mail: [email protected],whatsapp:+8613302615729.

The nature of the processing material is the primary consideration. Different materials vary significantly in terms of hardness, toughness, and wear resistance, and these characteristics directly impact die selection. For example, when processing materials with high hardness, it is necessary to choose a tungsten carbide die with high hardness and excellent wear resistance to ensure that the die does not suffer damage easily during long-term use.

The requirements for processing accuracy and surface quality are also of great importance. The accuracy and surface quality of products are core indicators for evaluating product quality. Based on these requirements, a tungsten carbide die with corresponding accuracy and surface finish should be precisely selected to ensure that the produced products meet the standards.

The requirements for processing volume and efficiency are important considerations for enterprise production. For mass production, the die needs to have outstanding wear resistance and a long service life to reduce the costs and time losses caused by frequent die replacement. For high-efficiency processing, a tungsten carbide die with high-speed cutting performance should be chosen to improve production speed.

The processing cost budget is also a key factor. While ensuring product quality and processing efficiency, enterprises need to comprehensively consider die costs and select cost-effective tungsten carbide dies to achieve effective cost control.

II. Diverse Types and Characteristics of Tungsten Carbide Dies

Tungsten carbide dies can be classified into various types and specifications according to different classification criteria.

Based on material classification, common types include cemented carbide dies, high-speed steel dies, and tungsten carbide composite dies. Cemented carbide dies are known for their high hardness, wear resistance, and thermal stability, making them suitable for processing scenarios with high precision and wear resistance requirements. High-speed steel dies have relatively high cutting performance and toughness, performing well in the processing of complex shapes and materials. Tungsten carbide composite dies combine the advantages of cemented carbide and high-speed steel, offering better overall performance.

Based on structural classification, they can be divided into integral dies, insert-type dies, and combined dies. Integral dies have a simple structure and are easy to manufacture, but they are relatively difficult to replace and maintain. Insert-type dies allow for easy replacement of worn parts, effectively reducing maintenance costs. Combined dies can flexibly combine different die parts according to processing requirements, enabling efficient production of multiple varieties in small batches.

Based on usage classification, they include stamping dies, injection molding dies, and die-casting dies. Different types of dies have distinct structural and performance characteristics and should be selected according to specific processing requirements.

III. Scientific Methods for Selecting Tungsten Carbide Dies

Selecting a suitable tungsten carbide die requires a comprehensive consideration of processing requirements, die types, and characteristics.

Selecting die materials based on processing materials is fundamental. According to the nature of the processing material, precisely match a tungsten carbide die material with corresponding hardness and wear resistance. For example, choose a cemented carbide die for processing high-hardness materials and a high-speed steel die for processing materials with good toughness.

Selecting die accuracy and finish based on processing accuracy and surface quality requirements is essential. For processing with high precision requirements, a high-precision die must be selected. For products with high surface quality requirements, a die with good surface finish should be chosen.

Selecting die types and structures based on processing volume and efficiency requirements is also important. Mass production is suitable for insert-type or combined dies with good wear resistance and long service life. High-efficiency processing should choose dies with high-speed cutting performance.

Comprehensively considering cost and cost-effectiveness is necessary. While ensuring product quality and processing efficiency, enterprises should conduct a comprehensive assessment of die costs and cost-effectiveness, select cost-effective tungsten carbide dies, reduce production costs, and enhance corporate competitiveness.

IV. Key Considerations in Selecting Tungsten Carbide Dies

When selecting tungsten carbide dies, the following key issues need to be noted:

Understanding the strength and reputation of die suppliers is crucial. Choosing a supplier with strength and a good reputation can ensure die quality and on-time delivery. This can be achieved by checking the supplier’s qualifications, performance records, and customer evaluations.

Verifying whether the technical parameters and performance indicators of the die meet processing requirements is necessary. Request the supplier to provide relevant technical documents and test reports as proof to ensure that the die performance meets the standards.

Considering the maintenance and upkeep of the die is important. Tungsten carbide dies require regular maintenance and upkeep during use to extend their service life. When selecting a die, evaluate the difficulty and cost of maintenance and upkeep.

Establishing a long-term cooperative relationship with the supplier is beneficial. This helps in obtaining better technical support and service guarantees. This can be achieved by signing long-term contracts and establishing regular communication mechanisms.

V. Conclusão

Selecting a suitable tungsten carbide die is of far-reaching significance for ensuring product quality, improving production efficiency, and reducing costs. Enterprises need to conduct a comprehensive analysis of processing requirements, gain an in-depth understanding of the types and characteristics of tungsten carbide dies, use scientific methods to select appropriate die types and structures, take into account cost and cost-effectiveness, and pay attention to die maintenance and upkeep. By comprehensively considering these factors, enterprises can accurately select tungsten carbide dies that meet processing requirements, laying a solid foundation for their high-quality development.