How to Precisely Select High-Precision Tungsten Carbide Dies

In today’s era of rapid industrial development, modern industrial manufacturing technologies are constantly evolving. High-precision tungsten carbide dies play an increasingly crucial role in industrial production. With their remarkable characteristics […]

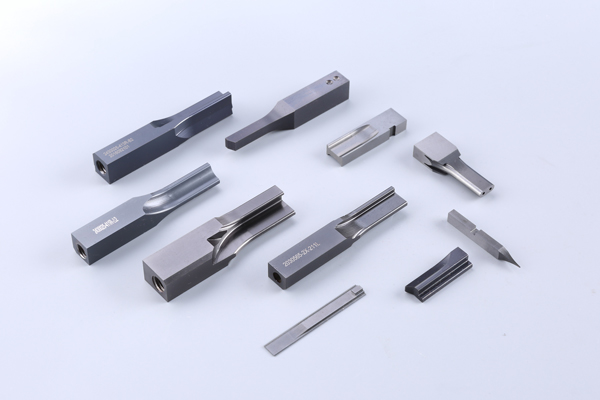

In today’s era of rapid industrial development, modern industrial manufacturing technologies are constantly evolving. High-precision tungsten carbide dies play an increasingly crucial role in industrial production. With their remarkable characteristics such as high hardness, excellent wear resistance, and superior heat resistance, they are widely applied in various key fields including metal processing, plastic molding, and die casting. However, the current market is flooded with a diverse range of high-precision tungsten carbide dies, and their quality varies significantly. How to select the appropriate dies in this complex market has become an urgent issue for many enterprises. This article will provide a detailed explanation of how to precisely select high-precision tungsten carbide dies from multiple key dimensions, including die material, manufacturing process, precision requirements, and service life.

I. Thoroughly Understand the Characteristics of High-Precision Tungsten Carbide Dies

Before selecting high-precision tungsten carbide dies, it is essential to have a deep understanding of their characteristics. High-precision tungsten carbide dies boast significant features such as high hardness, excellent wear resistance, superior heat resistance, and high precision. These characteristics enable them to maintain stable performance under long-term, high-load working conditions, ensuring that the produced products have high precision and quality, and laying a solid foundation for enterprises to create high-quality products.

O nosso negócio de fábrica: peças de metal duro, peças de molde, moldes de injeção médica, moldes de injeção de precisão, moldagem por injeção de teflon PFA, acessórios para tubos PFA. e-mail: [email protected],whatsapp:+8613302615729.

II. Carefully Select Suitable Die Materials

Die material is one of the core factors determining die performance. When selecting high-precision tungsten carbide dies, it is crucial to pay close attention to key indicators of the die material, including composition, hardness, wear resistance, and heat resistance. Generally, high-quality tungsten carbide materials exhibit high hardness and outstanding wear resistance, enabling them to maintain stable performance even in harsh working environments. Meanwhile, heat resistance is also an important factor that cannot be overlooked. Since dies are subject to high temperatures during the working process, materials with poor heat resistance are prone to deformation or damage, thereby affecting the service life of the dies and production efficiency. Therefore, selecting die materials with good heat resistance is of paramount importance.

III. Strictly Examine the Manufacturing Process

The manufacturing process has a crucial impact on the precision and service life of dies. When selecting high-precision tungsten carbide dies, a comprehensive examination of the manufacturing process is necessary. Firstly, great emphasis should be placed on the machining precision of the dies, which covers dimensional precision, shape precision, and positional precision. These precision indicators are directly related to the usage effect of the dies and the quality of the products. Any minor deviation may lead to defects in the products. Secondly, it is important to have an in-depth understanding of the manufacturing process of the dies, especially key processes such as heat treatment and surface treatment. Heat treatment can improve the internal microstructure and performance of the dies, significantly enhancing their hardness and wear resistance. Surface treatment can enhance the surface finish and demolding performance of the dies, effectively reducing the occurrence of material adhesion and wear, and thus extending the service life of the dies.

IV. Precisely Determine Precision Requirements

When selecting high-precision tungsten carbide dies, it is necessary to precisely determine the precision requirements based on specific production needs. Precision requirements mainly include dimensional precision, shape precision, and positional precision of the dies. Different production needs have varying requirements for die precision, so a reasonable selection should be made according to the actual situation. If the production process has extremely high requirements for product precision, then high-precision dies must be selected to ensure the stability and consistency of product quality. Conversely, if the production has relatively low requirements for precision, dies with slightly lower precision can be appropriately selected to reduce production costs and improve the economic benefits of the enterprise.

V. Fully Consider Service Life Factors

Service life is an important indicator for evaluating die performance. When selecting high-precision tungsten carbide dies, the service life of the dies should be fully taken into account. Generally, high-quality die materials, reasonable manufacturing processes, and proper usage methods can effectively extend the service life of the dies. Therefore, when selecting dies, it is necessary to comprehensively consider multiple factors such as die material, manufacturing process, and usage conditions, and prioritize dies with a long service life to reduce the die replacement costs of the enterprise and improve production efficiency.

VI. Prudently Select Reliable Suppliers

Selecting reliable suppliers is a key step in ensuring the selection of high-quality high-precision tungsten carbide dies. When choosing suppliers, it is necessary to conduct a comprehensive assessment of multiple aspects, including the supplier’s reputation, product quality, and after-sales service. You can gain an in-depth understanding of the supplier’s reputation and product quality by checking their qualification certificates and customer evaluations. At the same time, actively communicate with the suppliers and inquire about key issues such as the manufacturing process and service life of the dies to evaluate their professional level and service quality. Only by selecting suppliers with a good reputation, high-quality products, and excellent after-sales service can enterprises be provided with reliable die guarantees.

VII. Conduct On-Site Die Trials Without Fail

Conducting on-site die trials is an indispensable and crucial step when selecting high-precision tungsten carbide dies. Through die trials, you can intuitively understand the performance and precision of the dies, thereby accurately determining whether they meet production requirements. During the die trial process, carefully observe various aspects of the dies, such as machining precision, surface quality, and demolding performance, and communicate fully with the suppliers to promptly provide feedback on any issues discovered during the die trials. Only by ensuring that the die trial results meet production requirements can the final selection of these dies be confirmed, avoiding production accidents and quality issues caused by die problems.

VIII. Properly Arrange Maintenance and Upkeep Work

After selecting high-quality high-precision tungsten carbide dies, properly arranging maintenance and upkeep work is the key to ensuring that the dies maintain stable performance during use. Maintenance and upkeep work mainly include regularly cleaning the die surface, inspecting the wear condition of the dies, and promptly replacing severely worn parts. Through reasonable maintenance and upkeep, the service life of the dies can be effectively extended, production efficiency can be improved, and product quality can be enhanced, creating greater economic benefits for the enterprise.

In conclusion, selecting high-precision tungsten carbide dies requires a comprehensive consideration of multiple factors, including die material, manufacturing process, precision requirements, and service life. During the selection process, it is necessary to have a deep understanding of the characteristics and requirements of high-precision tungsten carbide dies and make scientific selections based on specific production needs. At the same time, selecting reliable suppliers and conducting on-site die trials are also important guarantees for ensuring the selection of high-quality dies. Finally, properly arranging maintenance and upkeep work enables the dies to always maintain optimal performance, providing strong support for the production and development of the enterprise.

Publicações relacionadas

- Treatment of Abnormal Situations in the Use of Tungsten Carbide Dies

- How to Ensure High Consistency in Batch Production of Tungsten Carbide Dies

- The Impact of Collaborative Research and Development on the Technological Progress of Tungsten Carbide Die

- How to Evaluate the Quality of Tungsten Carbide Processing?