The Critical Role of Tungsten Carbide in Precision Industries

Tungsten carbide, also known as cemented carbide, occupies a pivotal position in modern industrial fields due to its exceptional physical and chemical properties. Particularly in precision industries, the application of […]

Tungsten carbide, also known as cemented carbide, occupies a pivotal position in modern industrial fields due to its exceptional physical and chemical properties. Particularly in precision industries, the application of tungsten carbide is indispensable. This article will delve into the crucial role of tungsten carbide in precision and other industries by elaborating on its performance advantages, application areas, and its positive contribution to industrial development, thereby showcasing the unique value of tungsten carbide in modern industry.

I. Performance Advantages of Tungsten Carbide

The primary reason tungsten carbide plays a vital role in precision and other industries is attributed to its unique performance advantages. Specifically, tungsten carbide possesses the following notable characteristics:

O nosso negócio de fábrica: peças de metal duro, peças de molde, moldes de injeção médica, moldes de injeção de precisão, moldagem por injeção de teflon PFA, acessórios para tubos PFA. e-mail: [email protected],whatsapp:+8613302615729.

- Elevada dureza e resistência ao desgaste: Tungsten carbide boasts extremely high hardness, generally ranging from 82.0 to 93.6HRA, equivalent to 69 to 81HRC. Even at high temperatures of 500℃, its hardness remains largely unchanged, and it still maintains relatively high hardness at 1000℃. Additionally, its wear resistance is outstanding, enabling tools and equipment made of tungsten carbide to retain high precision and efficiency after prolonged use.

- High Strength and Toughness: Tungsten carbide not only exhibits high hardness but also possesses good strength and toughness. This allows it to withstand significant mechanical stress and impact without fracturing or deforming, thereby ensuring the stability and service life of tools.

- Excellent Heat and Corrosion Resistance: Tungsten carbide demonstrates superior heat resistance, capable of maintaining stable performance in high-temperature environments. Furthermore, it exhibits good corrosion resistance, making it suitable for use in certain special environments.

II. Application Areas of Tungsten Carbide in Precision Industries

Given its remarkable performance advantages, tungsten carbide finds extensive applications in precision industries. The following are several primary application areas:

- Cutting Tools: Tungsten carbide is widely utilized in the manufacture of various cutting tools, such as milling cutters, drills, and threading tools. Thanks to the high hardness and wear resistance of tungsten carbide, these cutting tools can maintain sharpness for extended periods, prolonging service life and enhancing machining accuracy and efficiency.

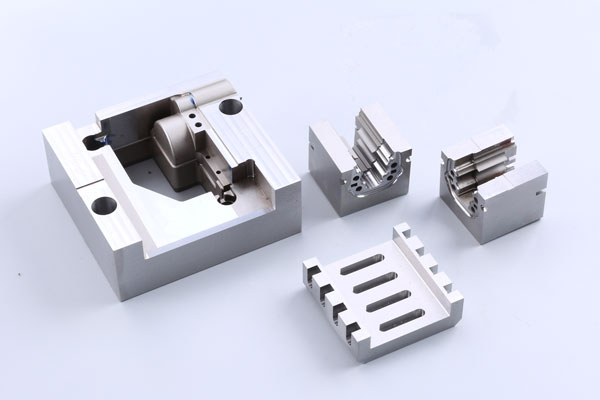

- Mold Manufacturing: In stamping operations, tungsten carbide is also an important material for mold manufacturing. Due to its high strength and hardness, tungsten carbide molds can withstand high-pressure and high-load working conditions while maintaining mold precision and stability.

- Wear-Resistant Parts: Tungsten carbide is frequently employed in the manufacture of wear-resistant parts, such as seal rings and guide rail materials. These parts play crucial roles in mechanical equipment, requiring resistance to significant friction and wear. The high hardness and wear resistance of tungsten carbide enable these parts to operate stably for extended periods in harsh working environments.

III. Contribution of Tungsten Carbide to Industrial Development

The widespread application of tungsten carbide in precision and other industries not only enhances production efficiency and product quality but also propels the development of the entire industry. Specifically, the contributions of tungsten carbide are mainly reflected in the following aspects:

- Improving Machining Accuracy and Efficiency: Due to the high hardness and wear resistance of tungsten carbide tools, machining accuracy and efficiency have been significantly improved. This is of paramount importance for precision industries requiring high-precision machining.

- Extending Equipment Service Life: Equipment and parts made of tungsten carbide have a longer service life, reducing the frequency of replacement and maintenance, thereby lowering production costs and enhancing production efficiency.

- Promoting Technological Innovation: With the continuous development and optimization of tungsten carbide materials, related technologies and processes are also undergoing innovation. This not only drives progress in the tungsten carbide industry but also provides impetus for technological innovation across the entire industrial sector.

IV. Conclusão

In summary, tungsten carbide plays a pivotal role in precision and other industries due to its exceptional performance advantages. It not only enhances production efficiency and product quality but also propels the development of the entire industry. With the continuous advancement of technology and the growing demands of industry, the application prospects of tungsten carbide will be even broader. In the future, we anticipate that tungsten carbide will showcase its unique value in more fields, contributing significantly to the development of modern industry.

Publicações relacionadas

- Guide to Tungsten Carbide Punches

- Trefilagem de perfis Polimento de matrizes: da precisão à nanoescala ao fabrico ecológico inteligente

- Caçonetes de carboneto de tungsténio: O "Titã Industrial" que está a alterar a eficiência do fabrico

- Garantia de qualidade sem defeitos para componentes de moldes de carboneto de tungsténio