Unlocking the Secrets of Tungsten Carbide Die Grinding

In various forming and processing fields, tungsten carbide dies are highly favored by numerous enterprises due to their excellent characteristics such as high hardness, high strength, and high wear resistance. […]

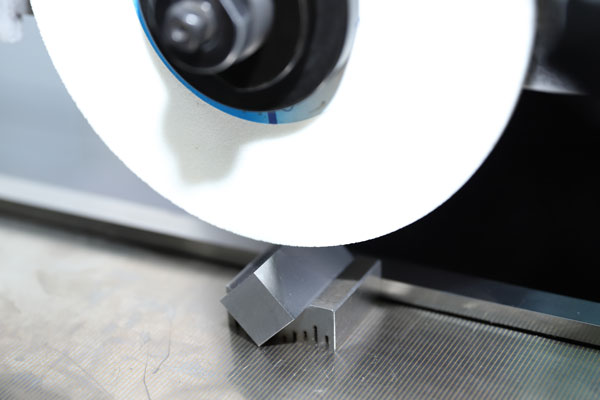

In various forming and processing fields, tungsten carbide dies are highly favored by numerous enterprises due to their excellent characteristics such as high hardness, high strength, and high wear resistance. However, these characteristics are like a double – edged sword, making the grinding process of tungsten carbide molds a highly challenging technical problem. To ensure the precision and service life of tungsten carbide molds, a series of strict requirements must be followed during the grinding process. This article will conduct an in – depth analysis of the key points that need to be met in the grinding process of tungsten carbide molds, providing valuable references for practitioners in related industries.

1. High Precision: The Foundation of Grinding Process

The primary goal of grinding tungsten carbide dies is to achieve high precision. The precision of the mold directly affects product quality and production efficiency. Once there is a deviation in mold precision, the products produced may have defects, which in turn will impact the smoothness of the entire production process.

O nosso negócio de fábrica: peças de metal duro, peças de molde, moldes de injeção médica, moldes de injeção de precisão, moldagem por injeção de teflon PFA, acessórios para tubos PFA. e-mail: [email protected],whatsapp:+8613302615729.

During the grinding process, it is crucial to control the precision of the grinding tools and accurately set the grinding parameters. Using high – precision grinding equipment is like equipping the mold processing with a “sharp blade”, which can ensure the accuracy of the processing. Selecting high – quality grinding materials is like giving the “sharp blade” an “edge”, making the molded products after grinding have precise dimensions and a smooth surface, perfectly meeting the high – precision requirements in the production process.

2. Uniform Grinding Force: The Guarantee of Grinding Quality

The uniformity of the grinding force during the grinding process of tungsten carbide dies cannot be ignored. If the grinding force is not uniform, the mold surface will have unevenness or uneven wear, which will not only significantly shorten the service life of the mold but also seriously affect product quality.

To ensure that the grinding force remains uniform and stable throughout the entire processing process, it is necessary to reasonably select grinding tools and grinding media. At the same time, the experience and skills of the operators also play a key role. Experienced operators can flexibly adjust the grinding force according to the actual situation, just like a skilled dancer who can precisely control the force of each movement to achieve the best grinding effect.

3. Reasonable Grinding Speed and Feed Rate: Balancing Efficiency and Quality

The selection of the grinding speed and feed rate is an art in the grinding process of tungsten carbide dies. Excessively high grinding speeds or feed rates will cause the mold surface to overheat, resulting in burns or cracks, as if “adding fuel to the fire” for the die. On the other hand, excessively low speeds and feed rates will reduce grinding efficiency and increase production costs, making the production progress as slow as “a snail’s pace”.

Therefore, when selecting the grinding speed and feed rate, it is necessary to comprehensively consider factors such as the material, shape, and grinding requirements of the die. Through reasonable adjustments, it is possible to not only “speed up the horse” to improve grinding efficiency but also avoid damaging the mold, achieving a perfect balance between efficiency and quality.

4. Cooling and Lubrication: The “Guardians” of the Grinding Process

During the grinding process of tungsten carbide dies, good cooling and lubrication are indispensable “guardians”. Due to the high hardness characteristics of tungsten carbide, a large amount of heat and friction force will be generated during the grinding process. If not cooled and lubricated in a timely manner, the grinding effect will be greatly reduced, and the die surface may have burns or cracks, as if “burying a time bomb” for the die.

Therefore, appropriate cooling fluids and lubricants should be used during the grinding process. The cooling fluid is like a “firefighter” that can promptly reduce the temperature of the grinding area. The lubricant is like “lubricating oil” that reduces the friction resistance during the grinding process, ensuring the smooth progress of the grinding.

5. Strict Quality Inspection: The Last Line of Defense for Quality Compliance

After the grinding process of tungsten carbide dies is completed, strict quality inspection is the last line of defense to ensure that the mold quality meets the standards. By testing indicators such as the dimensional accuracy, surface roughness, and hardness of the mold, a comprehensive assessment can be made to determine whether the mold meets the design requirements and production needs.

For unqualified molds, they should be repaired or re – processed in a timely manner to prevent them from entering the production process. At the same time, a complete quality management system should be established to monitor and record each link in the grinding process. This is like installing a pair of “eyes” for the die processing, which can promptly identify potential problems and take corresponding measures to ensure that the die quality is foolproof.

6. Professional Personnel: The Core Force of Grinding Process

The grinding process of tungsten carbide dies cannot be carried out without professional operators. These personnel should have rich practical experience and exquisite skill levels, and be able to skillfully master the use methods of various grinding tools and equipment, just like a highly skilled craftsman who can skillfully use various tools to create exquisite works.

At the same time, they also need to have a rigorous work attitude and a high sense of responsibility, and operate strictly in accordance with the process requirements during the grinding process. Through professional training and assessments, the skill levels and quality awareness of the operators can be continuously improved, providing a solid guarantee for the grinding quality of tungsten carbide molds.

7. Summary

The grinding process of tungsten carbide dies is a complex and delicate process that needs to meet multiple requirements such as high precision, uniform grinding force, reasonable grinding speed and feed rate, good cooling and lubrication, strict quality inspection, and professional personnel. Only by fully meeting these conditions can the precision and service life of tungsten carbide dies be ensured to reach the optimal state. With the continuous progress of technology and the application of innovative technologies, it is believed that the grinding process of tungsten carbide dies will be more efficient, precise, and reliable in the future, injecting strong impetus into the development of related industries.