A Comprehensive Guide to Using Tungsten Carbide

In the industrial field, tungsten carbide, also well – known as hard alloy, is truly a “powerhouse”. It is manufactured through powder metallurgy technology, combining metal carbides (such as tungsten […]

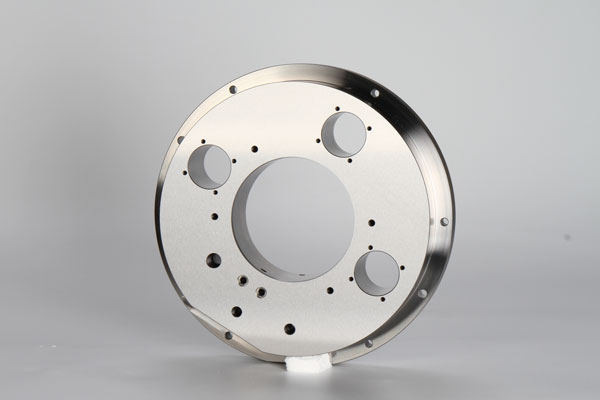

In the industrial field, tungsten carbide, also well – known as hard alloy, is truly a “powerhouse”. It is manufactured through powder metallurgy technology, combining metal carbides (such as tungsten carbide, titanium carbide, etc.) and metal binders (usually cobalt or nickel). With its outstanding properties of high hardness, high strength, high wear resistance, high thermal stability, and chemical stability, tungsten carbide finds extensive applications in industries like mechanical processing, mining, and oil drilling. However, it also has a “quirky” characteristic – relatively high brittleness. Therefore, special attention must be paid during its use to ensure its safe and efficient operation. Below is a detailed introduction to the precautions for using tungsten carbide.

Prevent Impact and Overload: Guard the “Safety Line” of Tungsten Carbide

Tungsten carbide boasts high hardness and excellent wear resistance, but this also makes it relatively fragile and highly sensitive to impact and overload. During use, never subject it to direct impacts, such as striking it with a metal hammer, as this can easily cause it to crack or chip. In addition, when installing or fixing tungsten carbide tools, ensure they are securely and stably mounted to prevent accidental damage caused by looseness.

Onze fabriek business: carbide onderdelen, schimmel onderdelen, medische spuitgietmatrijzen, precisie spuitgietmatrijzen, teflon PFA spuitgieten, PFA buismontage. e-mail: [email protected],whatsapp:+8613302615729.

Special Considerations for Installation and Fixation: Use Dedicated Fixtures

Due to its extremely low or non – magnetic nature, tungsten carbide cannot be fixed with magnets. Instead, dedicated work fixtures should be used to guarantee its stability and safety. During installation, carefully check whether the workpiece is firmly secured to avoid safety accidents caused by looseness. Meanwhile, the installation rotating shaft of the tungsten carbide tool must be accurately aligned with its center to ensure it does not deviate during operation.

Exercise Caution in Grinding and Cutting: Choose the Right Tools

When grinding or cutting tungsten carbide, the operation method and tool selection are of utmost importance. Its hard and brittle nature means that improper operations can easily lead to material cracking or damage. When performing these operations, select appropriate grinding agents and cutting tools, and ensure smooth and uniform operations. Moreover, the surface of tungsten carbide after grinding or cutting becomes extremely smooth and sharp. So, extreme care must be taken during handling and use to prevent scratches or punctures.

Pay Attention in Electrical Discharge Machining and Wire – Cutting: Adjust Parameters Correctly

During electrical discharge machining or wire – cutting of tungsten carbide, the high hardness and wear resistance may result in a relatively slow processing speed. At the same time, the surface after electrical discharge is prone to cracks and chipping. Therefore, when conducting these machining operations, reasonably adjust the processing parameters and programs according to the product’s usage conditions and requirements to ensure both processing quality and tool safety.

Take Storage and Maintenance Seriously: Ensure a Dry and Ventilated Environment

The storage and maintenance of tungsten carbide tools also require great attention. First, store them in a dry and ventilated environment to avoid moisture and corrosion. Second, regularly inspect and maintain the tools to promptly identify and address any issues. For example, if a tungsten carbide tool is found to have cracks or damage, immediately stop using it and replace it. For tools that will not be used for a long time, conduct appropriate maintenance and sealing to extend their service life.

Safety Precautions Are Essential: Wear Protective Gear

When using tungsten carbide tools, it is imperative to strictly comply with relevant safety operating procedures. Operators must wear appropriate protective gear, such as gloves and goggles, to prevent injuries caused by splashes or debris. Meanwhile, keep the work area clean and tidy to avoid damage to the tools or adverse effects on operation efficiency caused by debris and dust.

Conclusion and Recommendations: Remember for Safety and Efficiency

Tungsten carbide (hard alloy), as a high – performance material, has a wide range of applications. However, due to its characteristic brittleness and high hardness, special attention must be paid to safety precautions and operating procedures during use. By strictly adhering to the above – mentioned precautions and recommendations, the safe and efficient use of tungsten carbide tools can be ensured, their service life extended, and work efficiency improved while maintenance costs are reduced, bringing greater economic and social benefits to enterprises and individuals.

In short, when using tungsten carbide, one must remain highly vigilant and follow professional guidelines to ensure the safety of personnel and the normal operation of equipment.