Analysis of Grinding Processing for Tungsten Carbide Products

In the realm of industrial manufacturing, tungsten carbide, renowned as a hard alloy, stands out for its unparalleled high hardness, strength, and wear resistance, making it the material of choice […]

In the realm of industrial manufacturing, tungsten carbide, renowned as a hard alloy, stands out for its unparalleled high hardness, strength, and wear resistance, making it the material of choice for numerous critical components. However, these exceptional physical properties also render the processing of tungsten carbide, particularly grinding, a formidable challenge. This article will delve into a comprehensive and in-depth exploration of the grinding processing technology for tungsten carbide products, aiming to provide practical references and guidance for industry professionals.

1. The Unique Allure of Tungsten Carbide and the Challenges of Grinding

Tungsten carbide materials are celebrated for their high hardness and outstanding wear resistance, which makes them shine in high-end manufacturing sectors such as cutting tools and molds. However, these characteristics also pose significant difficulties for grinding. The high hardness necessitates the use of greater cutting forces and higher grinding temperatures during the grinding process, inevitably accelerating the wear of grinding tools and reducing processing efficiency. Meanwhile, the wear resistance of tungsten carbide makes it challenging to remove chips, further increasing the difficulty of processing.

Onze fabriek business: carbide onderdelen, schimmel onderdelen, medische spuitgietmatrijzen, precisie spuitgietmatrijzen, teflon PFA spuitgieten, PFA buismontage. e-mail: [email protected],whatsapp:+8613302615729.

2. Selecting the Optimal Grinding Tools to Tackle High Hardness

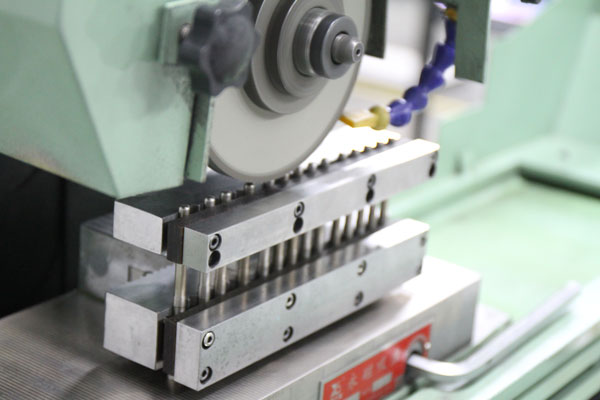

Given the high hardness of tungsten carbide materials, selecting appropriate grinding tools is of paramount importance. Diamond grinding wheels, renowned for their high hardness, wear resistance, and thermal stability, emerge as the preferred choice for grinding tungsten carbide. Additionally, depending on specific processing requirements and product shapes, we can flexibly select diamond grinding wheels with varying grit sizes, hardness levels, and bonding agents to achieve optimal grinding results.

3. Optimizing Process Parameters to Enhance Processing Efficiency

In the grinding of tungsten carbide materials, reasonable setting of process parameters is crucial for improving processing efficiency and ensuring product quality. Below are some key process parameters and optimization suggestions:

- Grinding Depth: It should be determined based on the material’s hardness and the performance of the grinding tool. Excessive depth leads to increased grinding forces, elevated temperatures, and accelerated tool wear, while insufficient depth reduces processing efficiency.

- Feed Rate: Adjustments should be made according to actual conditions. Excessive feed rates result in increased surface roughness and even burns, while too slow feed rates affect processing efficiency.

- Wheel Speed: Properly increasing the speed can increase the number of grinding passes per unit time, thereby enhancing processing efficiency. However, excessively high speeds may lead to elevated grinding temperatures and accelerated tool wear.

4. Coolants and Lubricants: Ensuring Processing Quality

The use of coolants and lubricants during the grinding process is of utmost importance. They not only effectively reduce grinding temperatures, minimize tool wear, but also improve processing quality. For the grinding of tungsten carbide materials, water-based coolants or oil-based lubricants are recommended. These fluids also aid in chip removal and maintaining the cleanliness of the processed surface.

5. Details in Processing: Not to Be Overlooked

During the grinding of tungsten carbide materials, we must also pay attention to the following points:

- Regular Inspection of Grinding Tools: Timely detection and replacement of severely worn tools are essential to ensure processing quality and efficiency.

- Maintaining a Clean Processing Environment: Avoiding interference from impurities and dust during the processing is crucial to prevent compromising processing quality and tool lifespan.

- Strengthening Operator Training: Enhancing the skill levels of operators ensures they can master grinding techniques and processes proficiently, thereby guaranteeing processing quality.

6. Looking Ahead: More Efficient and Precise Grinding of Tungsten Carbide

The grinding processing of tungsten carbide materials is undoubtedly a highly technical task. However, by meticulously selecting grinding tools, optimizing process parameters, reasonably using coolants and lubricants, and strengthening operator training, we are fully capable of overcoming these challenges to enhance processing efficiency and product quality. With the continuous advancement of technology and the emergence of novel grinding techniques, we have reason to believe that the future grinding of tungsten carbide materials will be even more efficient, precise, and reliable.

In this era brimming with challenges and opportunities, let us join hands to propel the development of tungsten carbide material grinding processing technology and contribute our strength to the prosperity of the industrial manufacturing sector.