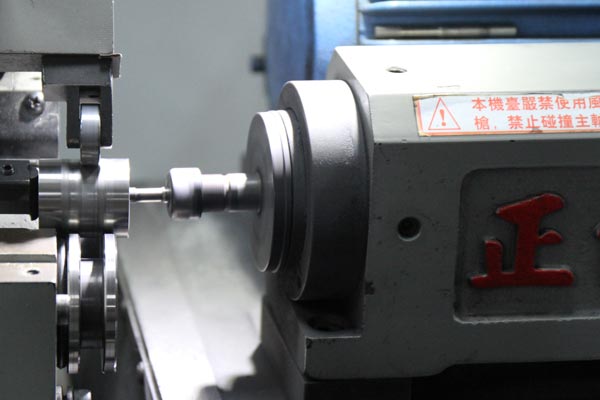

Evaluation and Improvement Directions of the Environmental Performance of Tungsten Steel Molds

Introduction In the wave of modern manufacturing industry’s vigorous development, various advanced tools are constantly emerging, driving the industry to move forward continuously. Among them, tungsten steel molds stand out […]

Inleiding

In the wave of modern manufacturing industry’s vigorous development, various advanced tools are constantly emerging, driving the industry to move forward continuously. Among them, tungsten steel molds stand out with their high hardness, excellent wear resistance, and good machinability, becoming an indispensable key tool in the manufacturing industry. However, with the global environmental awareness reaching an unprecedented height, environmental requirements have penetrated into various industries. Tungsten steel molds are also facing stricter environmental scrutiny. In this context, it is particularly urgent and significant to conduct a comprehensive evaluation of the environmental performance of tungsten steel molds and actively explore feasible improvement directions. This not only concerns the sustainable development of tungsten steel molds themselves but also plays a crucial role in ensuring that the manufacturing industry achieves an environmentally friendly transformation while developing efficiently.

Evaluation of the Environmental Performance of Tungsten Steel Molds

Raw Material Sources and Environmental Friendliness

The raw materials of tungsten steel molds mainly include elements such as tungsten, cobalt, and carbon. The mining and processing processes of these elements are like a double-edged sword. While providing the foundation for mold manufacturing, they also have an undeniable impact on the environment. From the perspective of raw material selection, the environmental friendliness of the sources is of utmost importance. Prioritizing suppliers with environmental certification is like putting a safety lock on the environmental quality of raw materials, ensuring that environmental requirements are strictly followed during the mining and processing processes and minimizing damage to the environment.

Onze fabriek business: carbide onderdelen, schimmel onderdelen, medische spuitgietmatrijzen, precisie spuitgietmatrijzen, teflon PFA spuitgieten, PFA buismontage. e-mail: [email protected],whatsapp:+8613302615729.

Environmental Friendliness in the Production Process

The production process of tungsten steel molds is complex, covering multiple key links such as smelting, casting, and heat treatment. Each link is like a potential pollution source, which may generate pollutants such as exhaust gas, wastewater, and solid waste. If these pollutants are not effectively controlled, they will cause serious pollution to the surrounding environment. Therefore, it is essential to strictly control the emission of pollutants during the production process and actively adopt advanced environmental protection technologies and equipment to build a solid environmental protection defense line for the production process and ensure that the entire production process complies with environmental standards.

Environmental Friendliness in the Usage Process

When tungsten steel molds are put into use, wear and damage are inevitable over time, resulting in a certain amount of waste. If this waste is not properly disposed of, it will be like a time bomb, causing pollution to the environment. Therefore, it is urgent to establish a complete waste recycling and disposal mechanism during the usage process. Through scientific and reasonable recycling and disposal methods, ensure the safe and environmentally friendly disposal of waste and avoid secondary environmental damage.

Environmental Friendliness in the Recycling and Reuse Process

Tungsten steel molds have high recycling value, like a treasure waiting to be explored. Through recycling and reuse, not only can production costs be effectively reduced, but also resource waste and environmental pollution can be minimized, achieving a win-win situation in terms of economic and environmental benefits. During the recycling and reuse process, environmental friendliness must also be emphasized. Adopting environmentally friendly recycling technologies and equipment ensures that the recycling and reuse process complies with environmental requirements, allowing this “treasure” to be fully explored and utilized under environmental protection conditions.

Improvement Directions for the Environmental Performance of Tungsten Steel Molds

Greening of Raw Materials

The selection of raw materials is the starting point of the environmental protection journey for tungsten steel molds. Actively promoting the greening of raw materials, choosing suppliers with environmental certification, and prioritizing the use of environmentally friendly raw materials are key measures to reduce environmental pollution from the source. At the same time, increasing research and development efforts to explore new types of environmentally friendly tungsten steel materials and reduce the use of harmful substances lay a solid foundation for improving the environmental performance of tungsten steel molds.

Cleaning of the Production Process

Promoting clean production technologies is the core task in the production process. Adopting advanced environmental protection equipment and technologies and strictly controlling the emission of pollutants are like installing an “environmental purification device” for the production process. By optimizing production processes and procedures, the generation of exhaust gas, wastewater, and solid waste can be reduced, reducing the pressure on the environment from the production source. In addition, strengthening energy management during the production process, improving energy utilization efficiency, and reducing energy consumption can achieve a green and low-carbon transformation of the production process.

Environmental Protection in the Usage Process

Establishing a complete waste recycling and disposal mechanism is the key link to ensuring environmental protection during the usage process. At the same time, strengthening the maintenance and upkeep of molds is like injecting a “longevity gene” into the molds, extending their service life and reducing waste generation. In addition, researching and developing new types of environmentally friendly lubricants and cutting fluids and other auxiliary materials can reduce environmental pollution during the processing process, making the usage process more environmentally friendly and efficient.

Resource Utilization in the Recycling and Reuse Process

Emphasizing resource utilization during the recycling and reuse process is an important direction for improving environmental performance. By researching and developing advanced recycling technologies and equipment, the recycling efficiency and quality can be improved, turning waste into treasure. At the same time, promoting research and development on the resource utilization of waste and converting waste into reusable resources can achieve resource recycling, reducing resource waste and environmental pollution.

Strengthening the Cultivation of Environmental Awareness

The cultivation of environmental awareness is the key soft power for improving the environmental performance of tungsten steel molds. Enterprises should strengthen the environmental awareness training and education for employees, making them deeply aware of the importance and urgency of environmental protection work, like planting a seed of environmental protection in the hearts of employees. At the same time, encouraging employees to actively participate in environmental protection work and put forward improvement suggestions can form a good atmosphere where everyone participates and jointly promotes, contributing their collective strength to improving the environmental performance of tungsten steel molds.

Conclusie

Tungsten steel molds, as key tools in modern manufacturing, have far-reaching significance in improving their environmental performance. Through the implementation of a series of measures such as the greening of raw materials, the cleaning of the production process, environmental protection in the usage process, resource utilization in the recycling and reuse process, and strengthening the cultivation of environmental awareness, the environmental pollution and resource waste during the production and usage of tungsten steel molds can be effectively reduced, injecting strong impetus into the sustainable development of the manufacturing industry and environmental protection work. Therefore, enterprises and relevant institutions should work together to strengthen research and development on the environmental performance of tungsten steel molds and contribute their wisdom and strength to achieving environmentally friendly sustainable development.

Verwante berichten

- Evaluation and Improvement Directions for the Environmental Performance of Tungsten Carbide Dies

- Comprehensive Analysis of Methods and Standards for Quality Inspection of Tungsten Carbide Dies

- Analysis of the Impact of Lubricant Selection on the Service Life of Tungsten Carbide Dies

- Strategies for Ensuring Dimensional Accuracy of Tungsten Carbide Dies