What’s the Differences Between High-Speed Steel and Tungsten Carbide

In the vast arena of industrial production, high-speed steel and tungsten carbide shine like two bright stars, each playing a pivotal role with their unique properties. Although both are high-quality […]

In the vast arena of industrial production, high-speed steel and tungsten carbide shine like two bright stars, each playing a pivotal role with their unique properties. Although both are high-quality tool materials, there are significant differences between them in terms of composition, characteristics, and application fields. Let’s delve into their disparities together.

Composition Differences: Laying the Foundation for Properties

High-Speed Steel: A Complex Alloy for Excellence

High-speed steel is an advanced alloy steel. Its composition is like a complex chemical tapestry, with elements such as carbon (C), molybdenum (Mo), cobalt (Co), tungsten (W), and chromium (Cr) intertwined. Carbon, as the fundamental element of steel materials, is a key factor in enhancing the hardness and strength of steel. The addition of alloy elements like molybdenum, cobalt, tungsten, and chromium further boosts the wear resistance, corrosion resistance, and high-temperature strength of high-speed steel.

Onze fabriek business: carbide onderdelen, schimmel onderdelen, medische spuitgietmatrijzen, precisie spuitgietmatrijzen, teflon PFA spuitgieten, PFA buismontage. e-mail: [email protected],whatsapp:+8613302615729.

Tungsten Carbide: Tungsten Takes the Lead

Tungsten carbide, also known as cemented carbide, has tungsten as its core element, with common additional elements including cobalt and nickel. The high melting point and high density of tungsten carbide are attributed to the synergistic effects of tungsten and other alloy elements. In particular, tungsten carbide (in the form of a compound), as one of the main components of tungsten carbide, plays a crucial role in improving its hardness and wear resistance.

Characteristic Distinctions: Each Showcasing Unique Strengths

High-Speed Steel: Versatile Performance for Complex Conditions

- Wear and Hardness Excellence: High-speed steel is renowned for its outstanding hardness and wear resistance. In high-load, high-speed working environments such as cutting, stamping, and cold extrusion, it acts like a fearless warrior, easily tackling various challenges and demonstrating卓越 performance.

- Remarkable High-Temperature Strength: Even under high-temperature conditions, high-speed steel can maintain relatively high hardness and strength, making it an ideal choice for high-temperature cutting and heat treatment applications.

- Goede corrosiebestendigheid: Due to the unique effects of its alloy components, high-speed steel also possesses good corrosion resistance, enabling it to work stably in some corrosive environments and providing a reliable guarantee for production.

Tungsten Carbide: Thriving in High-Temperature, High-Strength Environments

- High Melting Point for High-Temperature Applications: Tungsten carbide has an extremely high melting point, which makes it less prone to softening in high-temperature environments. Like a steadfast guardian, it is particularly suitable for manufacturing high-temperature tools and components.

- High Density and Strength Advantages: The high density of tungsten carbide gives it unique advantages in applications requiring high weight or high quality. Meanwhile, its relatively high strength can meet various demanding working requirements.

- Excellent Wear and Corrosion Resistance: Similar to high-speed steel, tungsten carbide also boasts outstanding wear and corrosion resistance, allowing it to maintain stable performance in various harsh working environments.

Different Application Fields: Precise Positioning for Distinct Roles

High-Speed Steel: A Mainstay in Mechanical Manufacturing

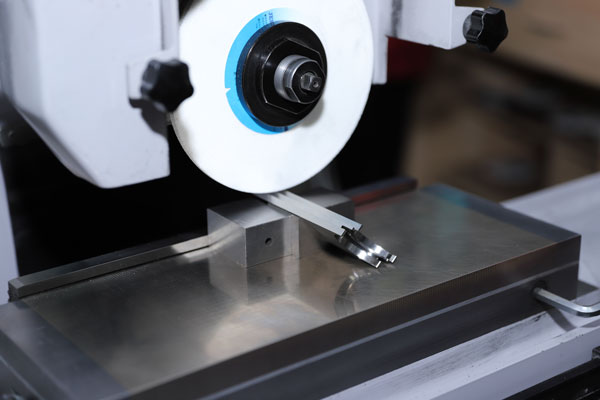

With its outstanding wear resistance, hardness, and high-temperature strength, high-speed steel plays a vital role in the field of tool manufacturing. Tools such as turning tools, milling cutters, and drills all rely on it. In addition, high-speed steel also plays an indispensable role in fields such as forging dies, cold stamping dies, and automobile part manufacturing.

Tungsten Carbide: A Darling in High-Tech Industries

Due to its high melting point, high density, and wear resistance, tungsten carbide is widely used in the aerospace field, such as in the manufacture of aircraft engine components. At the same time, in high-tech fields like medical devices, nuclear energy equipment, and the electronics industry, tungsten carbide has also become a highly favored material thanks to its unique physical and chemical properties.

Price and Market: Different Considerations Behind the Differences

High-speed steel, as a widely used tool steel, has a relatively affordable market price and a stable supply, which can meet the needs of most industrial production. In contrast, tungsten carbide usually has a higher price due to the use of rare and expensive elements (such as tungsten and cobalt) in its manufacturing process. However, in high-tech industries, its excellent performance often makes price a secondary consideration, as enterprises focus more on the high quality and performance it can bring to products.

Environment and Sustainability: Building a Future Together with Green Development

In terms of environmental protection, the mining and processing of high-speed steel and tungsten carbide may have certain impacts on the environment. However, with the continuous progress of technology and the strengthening of environmental regulations, these impacts are gradually being controlled. From the perspective of sustainability, efficient utilization and recycling of these materials are crucial for reducing resource waste and environmental pollution. We should actively explore more environmentally friendly and sustainable production and usage methods, so that these two high-quality materials can not only contribute to industrial development but also coexist harmoniously with the natural environment.