Advantages of New Tungsten Carbide Die Materials

I. Introduction In the context of the vigorous development of modern manufacturing, dies, as the core tools in the production process, play a decisive role in product quality, production efficiency, […]

I. Введение

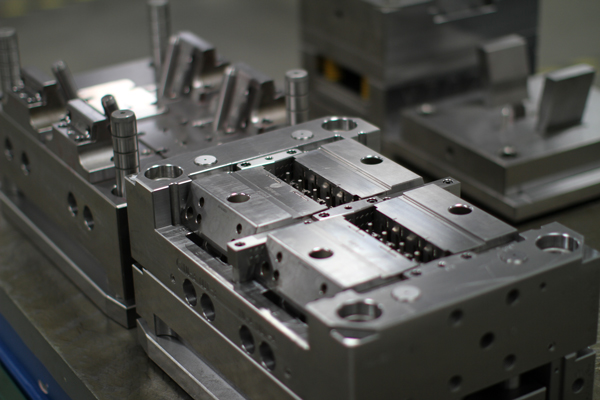

In the context of the vigorous development of modern manufacturing, dies, as the core tools in the production process, play a decisive role in product quality, production efficiency, and cost control, much like the foundation of a building. Tungsten carbide die materials have long held a key position in the die manufacturing field due to their remarkable characteristics such as high hardness, wear resistance, and corrosion resistance. In recent years, with the surging wave of technological advancement and continuous process innovation, new tungsten carbide die materials have emerged like shining stars. These new materials, with their unique advantages, have significantly expanded the application scope of tungsten carbide dies in the manufacturing industry. This article will delve into the advantages of new tungsten carbide die materials, providing valuable references for the development of the die manufacturing industry.

II. New Tungsten Carbide Die Materials: A Fusion of Tradition and Innovation

New tungsten carbide die materials are not created out of thin air. They are developed on the basis of traditional tungsten carbide materials through meticulous optimization of composition, bold improvement of processes, and active introduction of new technologies. These new materials not only inherit the excellent characteristics of tungsten carbide, such as high hardness, wear resistance, and corrosion resistance, but also achieve a leap in performance. The toughness, thermal fatigue resistance, and impact resistance of the materials have been further enhanced, enabling tungsten carbide dies to maintain stable and reliable performance even in complex and harsh working environments, providing a solid guarantee for the efficient operation of dies.

Наш завод занимается: твердосплавные детали, детали пресс-форм, медицинские пресс-формы для литья под давлением, прецизионные пресс-формы для литья под давлением, литье тефлона PFA, фитинги для труб PFA. e-mail: [email protected],whatsapp:+8613302615729.

III. Remarkable Advantages of New Tungsten Carbide Die Materials

1. The Perfect Combination of High Hardness and Wear Resistance: Rigid yet Flexible

New tungsten carbide die materials perfectly inherit the high hardness and wear resistance of traditional tungsten carbide materials. This characteristic allows them to maintain excellent surface quality and precise dimensional accuracy during high-speed and high-load cutting processes, just like a skilled craftsman. Moreover, by optimizing the composition and improving the heat treatment process, the hardness and wear resistance of the new materials have been further enhanced. This means that the service life of the dies is effectively extended, reducing the costs and time losses caused by frequent die replacement and providing strong support for the efficient production of enterprises.

2. Excellent Toughness and Impact Resistance: Unyielding under Pressure

Compared with traditional tungsten carbide materials, new tungsten carbide die materials exhibit outstanding toughness and impact resistance while maintaining high hardness. During the operation of dies, they inevitably face the challenges of impact and vibration. The new materials, like a warrior clad in armor, can maintain excellent stability and reliability under such impacts, significantly reducing the risk of die failure due to brittle fracture. This advantage makes new tungsten carbide dies shine in industries such as aerospace and automotive manufacturing, which require high-impact load resistance, becoming the preferred materials for die manufacturing in these fields.

3. Good Thermal Fatigue Resistance: Standing the Test of Heat

In the die manufacturing process, high-temperature environments are a severe challenge that dies must confront. Prolonged exposure to high temperatures can easily cause dies to develop cracks and deformations due to thermal fatigue, seriously affecting their performance and service life. New tungsten carbide die materials have successfully improved their thermal fatigue resistance by optimizing the composition and introducing advanced heat treatment technologies. Under the “roasting” of high temperatures, the dies can still maintain stable performance, effectively reducing the problem of die failure caused by thermal fatigue and providing a reliable guarantee for the long-term stable operation of dies in high-temperature environments.

4. Excellent Corrosion Resistance: The Guardian against Corrosion

New tungsten carbide die materials not only maintain high hardness but also possess outstanding corrosion resistance. In industries such as chemical engineering and electroplating, dies often need to come into contact with corrosive media. Traditional materials are often unable to withstand the erosion of corrosion, leading to a decline in die surface quality and performance damage. The new tungsten carbide die materials, like a loyal guardian, can maintain good surface quality and performance when in contact with corrosive media, greatly extending the service life of the dies and providing an ideal choice for die applications in these industries.

5. Easy Processing and Repair: Convenient and Efficient

New tungsten carbide die materials have good machinability and repairability, which brings great convenience to die manufacturing and maintenance. During the manufacturing process, more efficient processing methods can be adopted to improve production efficiency and reduce manufacturing costs. In case of maintenance, advanced repair technologies can be used to quickly restore the performance of the dies, reducing maintenance time and costs. At the same time, the good machinability also enables new tungsten carbide die materials to handle complex die manufacturing with ease, meeting the manufacturing requirements of various complex dies.

6. Environmental Protection and Sustainable Development: The Pioneer of Greenness

In today’s era when environmental awareness is increasingly strong, new tungsten carbide die materials fully consider the requirements of environmental protection and sustainable development during the research and development process. By optimizing the composition and process, the use of elements and substances harmful to the environment is reduced, and energy consumption and waste emissions during the production process are lowered. This advantage makes new tungsten carbide die materials stand out in terms of environmental protection and sustainable development, in line with the trend of the times and providing strong support for the green transformation of the die manufacturing industry.

IV. Broad Application Prospects of New Tungsten Carbide Die Materials

With the rapid development and in-depth transformation and upgrading of the manufacturing industry, higher requirements have been placed on the performance and quality of dies. New tungsten carbide die materials, with their unique advantages, show broad application prospects in the die manufacturing field. In the future, with the continuous progress of technology and the continuous innovation of processes, new tungsten carbide die materials will play an even more important role in high-end fields such as aerospace, automotive manufacturing, and precision machinery, injecting strong impetus into the development of these industries.

V. Заключение

New tungsten carbide die materials, based on characteristics such as high hardness, wear resistance, and corrosion resistance, integrate advantages such as excellent toughness, thermal fatigue resistance, and impact resistance, demonstrating strong vitality and broad development space in the die manufacturing field. With the continuous innovation of technology and the improvement of processes, new tungsten carbide die materials will undoubtedly play a more crucial role in promoting the development of the die manufacturing industry. At the same time, we should also pay high attention to the environmental protection and sustainable development issues of new tungsten carbide die materials and actively promote their development in a greener and more environmentally friendly direction, contributing to the sustainable development of the die manufacturing industry.