Exploring the Causes and Prevention Measures of Deformation in Tungsten Carbide Dies

In the grand landscape of industrial production, tungsten carbide dies, with their high strength, high hardness, and excellent wear resistance, occupy a pivotal position and are widely applied in numerous […]

In the grand landscape of industrial production, tungsten carbide dies, with their high strength, high hardness, and excellent wear resistance, occupy a pivotal position and are widely applied in numerous production processes. However, even with such remarkable performance, tungsten carbide dies are not entirely immune to deformation issues during use. Once a die deforms, the quality and precision of the products will be significantly compromised, production efficiency will decline, and it may even lead to serious production accidents. Therefore, delving deeply into the causes of deformation in tungsten carbide dies and exploring practical prevention measures are of great significance for ensuring the stability of the production process and enhancing product quality.

The Roots of Deformation in Tungsten Carbide Dies: A Complex Interplay of Factors

Material Pitfalls: Internal Defects and Process Imbalance

The deformation of tungsten carbide dies is closely related to the material itself. If the tungsten carbide material is of subpar quality, harboring internal defects or having an uneven composition, these hidden troubles will gradually surface during the die’s use, acting as triggers for deformation. Moreover, an unreasonable heat treatment process for the material can result in uneven internal stress distribution, like planting time bombs that eventually lead to die deformation.

Наш завод занимается: твердосплавные детали, детали пресс-форм, медицинские пресс-формы для литья под давлением, прецизионные пресс-формы для литья под давлением, литье тефлона PFA, фитинги для труб PFA. e-mail: [email protected],whatsapp:+8613302615729.

Design Flaws: Complex Structures and Stress Concentration

Unreasonable die design is another important factor contributing to deformation. If the die’s structural design is overly complex or contains weak links, it is highly prone to stress concentration. Just as in bridge design, where improper structural parts bear excessive pressure and are prone to damage, dies with stress concentration are likely to deform during use. Additionally, uneven wall thickness or abrupt cross-sectional changes in the die can also cause deformation during heat treatment or use due to uneven force distribution.

Processing Errors: Improper Operations and Parameter Imbalance

Improper operations during the processing stage can also pose a deformation risk to tungsten carbide dies. For example, unreasonable cutting parameter settings, excessive cutting forces, or high cutting heat can all adversely affect the die and lead to deformation. Furthermore, inadequate cooling and lubrication during processing can exacerbate the deformation risk, similar to how a machine lacking sufficient lubrication during operation is prone to wear and malfunctions.

Usage Missteps: Operational Violations and Overload

Improper use or overload operation during the die’s service life is a common cause of deformation. Overloading subjects the die to excessive pressure and impact forces, exceeding its load-bearing capacity and triggering deformation. At the same time, uneven cooling or sudden temperature changes during the die’s use can also cause deformation due to the principle of thermal expansion and contraction.

Maintenance Neglect: Long-term Operation and Hidden Trouble Accumulation

A lack of proper maintenance and upkeep is also a significant factor leading to deformation in tungsten carbide dies. If the die is used continuously for a long time without timely maintenance and inspection, wear will gradually intensify, and internal stress will accumulate continuously. These issues, like a snowball rolling downhill, will eventually lead to die deformation.

Prevention Strategies for Deformation in Tungsten Carbide Dies: A Multi-pronged Approach

Stringent Material Selection and Process Optimization: Laying a Solid Quality Foundation

Selecting high-quality tungsten carbide materials is crucial for preventing deformation. Opt for premium materials with uniform composition and no internal defects to build a solid foundation for die quality. Simultaneously, implement a reasonable heat treatment process to ensure even internal stress distribution in the material, enhancing the die’s stability and durability, just like laying a sturdy foundation for a skyscraper.

Scientific Die Design: Optimizing Structure for Enhanced Performance

Reasonable die design is a key prevention measure. During the design process, avoid overly complex die structures or weak links, strive to maintain uniform wall thickness, and minimize cross-sectional changes. Additionally, leverage advanced technologies such as Computer-Aided Design (CAD) and Finite Element Analysis (FEA) to optimize the die design, improving its structural strength and stability to better cope with various usage scenarios.

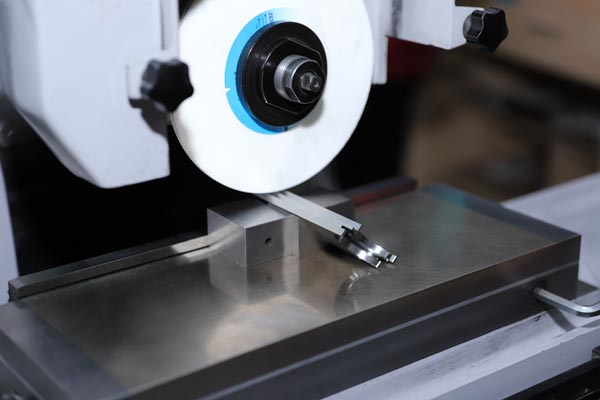

Precision Processing and Strict Quality Control: Ensuring Production Details

In the processing stage, adopt reasonable cutting parameters and cooling lubrication methods to minimize the impact of cutting forces and cutting heat on the die. At the same time, strengthen quality control to ensure that processing accuracy and surface quality meet requirements, reducing the deformation risk caused by improper processing. This is akin to crafting a fine piece of art, where every detail needs meticulous polishing and strict quality inspection.

Standardized Usage and Regular Maintenance: Extending Service Life

During use, strictly adhere to the operating procedures for the die, avoiding overload operation and sudden temperature changes. Establish a regular maintenance and inspection system to promptly identify and address any issues with the die, extending its service life and stability and ensuring it remains in good working condition.

Introducing Innovative Technologies and Materials: Opening Up New Prevention Paths

With the rapid development of technology, the emergence of new materials and technologies provides new ideas and methods for preventing deformation in tungsten carbide dies. For example, adopting new coating technologies can enhance the die’s wear resistance and anti-deformation ability; utilizing advanced numerical simulation technologies for die optimization design can help identify potential problems in advance and reduce the deformation risk. These innovative measures inject new vitality into the prevention of deformation in tungsten carbide dies.

Conclusion: Continuous Exploration for Industrial Progress

The causes of deformation in tungsten carbide dies during use are complex and multifaceted, involving material, design, processing, usage, and maintenance aspects. To effectively prevent deformation, a comprehensive approach is required, taking measures from multiple angles. By optimizing material selection and heat treatment processes, improving die design, implementing precision processing and strict quality control, standardizing usage and maintenance, and introducing new technologies and materials, the risk of deformation in tungsten carbide dies during use can be significantly reduced, improving production efficiency and product quality. Meanwhile, with the continuous advancement of technology, we should keep exploring and innovating to find more effective solutions, better address issues such as deformation in tungsten carbide dies, and drive industrial production towards higher quality and greater efficiency.

Related Posts

- Application and Special Requirements of Tungsten Carbide Die in the Electronics Industry

- Analysis of Common Faults and Countermeasures of Tungsten Carbide Die

- How to Comprehensively Ensure the Stability of Tungsten Carbide Dies under High Loads

- Selection Basis for Wear-Resistant Coating Materials of Tungsten Carbide Die