Exploration of Surface Treatment Technologies for Tungsten Carbide Dies

I. Introduction In the context of the booming manufacturing industry, tungsten carbide dies have become indispensable key tools in numerous production processes, thanks to their high hardness, excellent wear resistance, […]

I.はじめに

In the context of the booming manufacturing industry, tungsten carbide dies have become indispensable key tools in numerous production processes, thanks to their high hardness, excellent wear resistance, high heat resistance, and outstanding corrosion resistance. However, the surface quality of tungsten carbide dies serves as a “barometer” of their performance, directly influencing the die’s service life, machining accuracy, and the quality of the final products. Therefore, delving into the surface treatment technologies for tungsten carbide dies holds extremely significant practical importance for enhancing die performance, reducing production costs, and extending die service life. This article will conduct a detailed exploration of the key elements, technological methods, and development trends of surface treatment technologies for tungsten carbide dies.

II. Key Elements of Surface Treatment Technologies for Tungsten Carbide Dies

(A) Surface Roughness: The “Microscopic Code” Influencing Performance

Surface roughness is one of the crucial factors affecting the performance of tungsten carbide dies. From a microscopic perspective, lower surface roughness results in smoother contact between the die and the workpiece, thereby reducing friction. This not only helps improve the die’s wear resistance but also significantly enhances the machining accuracy and surface quality of the products. Imagine a rough-surfaced die in frequent contact with a workpiece; it’s like sandpaper rubbing against an object, continuously wearing down both the workpiece and itself. In contrast, a smooth-surfaced die is akin to a mirror, minimizing such unnecessary wear. Therefore, reducing surface roughness is a vital step in the manufacturing process of tungsten carbide dies.

当社の工場事業:超硬部品、金型部品、医療用射出成形金型、精密射出成形金型、テフロンPFA射出成形、PFAチューブ継手。電子メール:[email protected],whatsapp:+8613302615729。

(B) Surface Hardness: The “Sturdy Armor” for Performance

Surface hardness is an important indicator for evaluating the performance of tungsten carbide dies. Higher surface hardness acts as a sturdy armor for the die, enhancing its wear resistance and corrosion resistance, and thus extending its service life. Advanced surface treatment technologies, such as heat treatment and chemical vapor deposition, are like subjecting the die to a “strengthening training” program, significantly increasing its surface hardness. For example, a tungsten carbide die that has undergone heat treatment experiences a substantial boost in surface hardness, enabling it to maintain stable performance in high-load, high-wear working environments.

(C) Surface Topography: The “Invisible Promoter” for Performance Optimization

Surface topography also has a non-negligible impact on the performance of tungsten carbide dies. A reasonable surface topography can cleverly reduce the contact area between the die and the workpiece, similar to adding a lubricant between two objects, lowering the friction coefficient and thereby improving the die’s wear resistance. Additionally, surface topography can influence the die’s lubrication performance and heat dissipation performance. A well-designed surface topography enables lubricants to adhere more effectively to the die surface, accelerating heat dissipation and ensuring the die maintains an optimal temperature during operation.

III. Technological Methods of Surface Treatment for Tungsten Carbide Dies

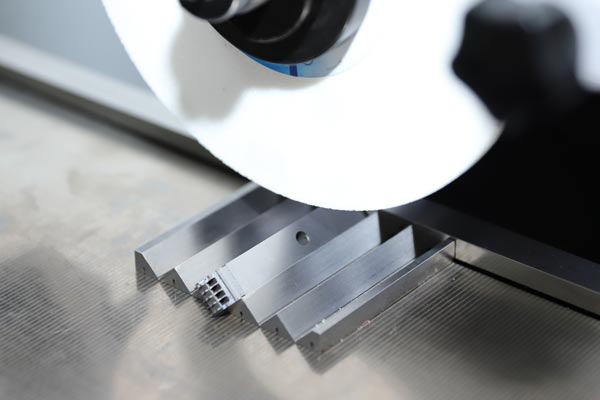

(A) Grinding and Polishing: The “Basic Cosmetic Surgery” for Surface Treatment

Grinding and polishing are fundamental methods for surface treatment of tungsten carbide dies, akin to performing “basic cosmetic surgery” on the die. Through grinding and polishing, defects such as burrs and oxide layers on the die surface can be removed, similar to eliminating blemishes on the skin, reducing surface roughness, and improving surface quality. Selecting appropriate grinding tools and polishing pastes during the grinding and polishing process is crucial, just as choosing the right skincare products is essential. At the same time, it is necessary to strictly control parameters such as pressure, speed, and time to ensure the achievement of the desired surface quality.

(B) Electrochemical Polishing: The “Magic Wand” for Efficient Treatment

Electrochemical polishing is an efficient surface treatment method for tungsten carbide dies, functioning like a “magic wand.” Through electrolysis, it can precisely remove microscopic irregularities and oxides on the die surface, resulting in a smooth and uniform surface. Compared with traditional polishing methods, electrochemical polishing offers significant advantages such as fast processing speed, excellent results, and no pollution. It is particularly suitable for treating tungsten carbide dies with complex shapes and high dimensional accuracy requirements, similar to fine polishing a complex-shaped handicraft without damaging it.

(C) High-Frequency Surface Quenching: The “Rapid Heating Technique” for Hardness Enhancement

High-frequency surface quenching is a method that heats the die surface using high-frequency induction currents and then rapidly cools it, functioning like a “rapid heating technique” for the die. This method can increase the surface hardness and wear resistance of the die, especially when treating easily worn parts of tungsten carbide dies, such as cavities and cutting edges. High-frequency surface quenching offers advantages such as fast heating speed, thin heated layer, and minimal deformation, similar to precisely strengthening a specific part of the die without altering its overall performance.

(D) Chemical Vapor Deposition: The “Film Magic” for Performance Improvement

Chemical vapor deposition is a method that forms a thin film with special properties on the die surface through chemical reactions, akin to casting a “magic film” over the die. This film is characterized by high hardness, excellent wear resistance, and strong corrosion resistance, significantly extending the die’s service life. Chemical vapor deposition offers advantages such as uniform coating, strong adhesion, and outstanding performance, similar to dressing the die in a sturdy protective suit that enables it to maintain stable performance in harsh working environments.

(E) Abrasive Flow Polishing: The “Fine Sculptor” for Complex Structures

Abrasive flow polishing is a method that uses specially formulated abrasive media to pass through the die surface under high pressure for fine machining, functioning like a “fine sculptor.” It is particularly suitable for treating tungsten carbide dies with complex structures, such as cavities and channels. Abrasive flow polishing offers advantages such as high machining accuracy, excellent machining results, and no damage to the workpiece, similar to performing a delicate dance in a microscopic world to achieve extremely high surface quality for the die.

IV. Development Trends of Surface Treatment Technologies for Tungsten Carbide Dies

(A) Green and Environmentally Friendly: The “Ecological Choice” in Line with the Times

With the continuous improvement of environmental awareness, green and environmentally friendly surface treatment technologies for tungsten carbide dies will become the mainstream trend in the future, representing the “ecological choice” in line with the times. In the future, more research and development efforts should be made to develop surface treatment technologies that are pollution-free and energy-efficient, reducing waste emissions and energy consumption during the production process. This is akin to finding a sustainable development path in a lush green forest, enabling surface treatment technologies for tungsten carbide dies to progress steadily on an environmentally friendly track.

(B) Intelligence: The “Smart Transformation” Empowered by Technology

Intelligence is an important development direction for surface treatment technologies of tungsten carbide dies, representing a “smart transformation” empowered by technology. By introducing intelligent equipment and technologies, the automation, digitization, and intelligent control of the surface treatment process can be achieved. This is similar to installing a “smart brain” in the traditional production process, improving processing efficiency and quality stability. For example, an intelligent control system can automatically adjust processing parameters according to the material, shape, and treatment requirements of the die, achieving precise machining.

(C) High Precision: The “Fine Pursuit” to Meet Demands

As the manufacturing industry places increasingly higher requirements on product quality and machining accuracy, high-precision surface treatment technologies for tungsten carbide dies will receive more attention, representing the “fine pursuit” to meet market demands. In the future, more high-precision and efficient surface treatment technologies should be developed to meet the needs of the manufacturing industry for high-precision dies. This is similar to performing a delicate dance in a microscopic world to achieve an even higher level of precision in surface treatment for tungsten carbide dies.

(D) Diversification: The “Diverse Development” to Adapt to Different Fields

Tungsten carbide dies have a wide range of applications, and the requirements for surface treatment technologies vary across different fields. Therefore, diversification is an inevitable development trend for surface treatment technologies of tungsten carbide dies, representing “diverse development” to adapt to different fields. In the future, more diverse surface treatment technologies should be developed to meet the needs of different fields for tungsten carbide dies. For example, specialized surface treatment technologies should be developed to meet the high-strength and high-corrosion-resistance requirements of dies in the aerospace field, and corresponding treatment solutions should be researched to meet the high-precision and low-pollution requirements of dies in the electronics industry.

V.結論

Surface treatment technologies for tungsten carbide dies are important means to improve die performance, reduce costs, and extend service life. By selecting appropriate surface treatment technological methods, similar to equipping the die with a set of “performance keys,” the surface quality, hardness, and wear resistance of tungsten carbide dies can be significantly improved. In the future, with the continuous progress of technology and the enhancement of environmental awareness, surface treatment technologies for tungsten carbide dies will develop in the directions of being green and environmentally friendly, intelligent, high-precision, and diverse, injecting stronger impetus into the development of the manufacturing industry.