Application Characteristics and Prospects of Tungsten Carbide Die in the Electronic Industry

In the era when technology is surging forward with great momentum, the electronic industry is undergoing unprecedented transformation and rapid development. There is an ever – increasing demand for high […]

In the era when technology is surging forward with great momentum, the electronic industry is undergoing unprecedented transformation and rapid development. There is an ever – increasing demand for high – precision and high – quality products in the market. In this context, tungsten carbide die, with its unique physical and chemical properties, is playing an increasingly crucial role in the electronic industry. This article will conduct an in – depth analysis of the application characteristics of tungsten carbide die in the electronic industry and explore how it can inject strong impetus into the high – quality development of the electronic industry.

I. The Essential Characteristics of Tungsten Carbide Die

Tungsten carbide die, also known as cemented carbide die, is an alloy material formed by ingeniously combining hard compounds of refractory metals with binding metals through powder metallurgy processes. This material boasts a series of excellent properties, including high hardness, strong wear resistance, good strength and toughness, heat resistance, and corrosion resistance. Notably, it can still maintain good hardness and wear resistance under high – temperature conditions. This characteristic enables the tungsten carbide die to maintain precise dimensions and stable performance during the machining process for an extended period, providing a solid foundation for high – precision manufacturing.

Unser Fabrikgeschäft: Hartmetallteile, Formteile, medizinische Spritzgussformen, Präzisionsspritzgussformen, Teflon-PFA-Spritzguss, PFA-Rohrverschraubungen. E-Mail: [email protected],whatsapp:+8613302615729.

II. The Stringent Requirements of the Electronic Industry for Dies

In the highly precise field of the electronic industry, product precision and quality are the lifeblood of enterprises. The components of electronic products often need to meet precision standards at the micrometer or even nanometer level, which places extremely demanding requirements on the manufacturing precision and stability of dies. Moreover, given the extremely rapid update and iteration speed of electronic products, the durability and service life of dies directly affect cost control and the market competitiveness of products.

III. The Diverse Applications of Tungsten Carbide Die in the Electronic Industry

High – Precision Manufacturing Paragon

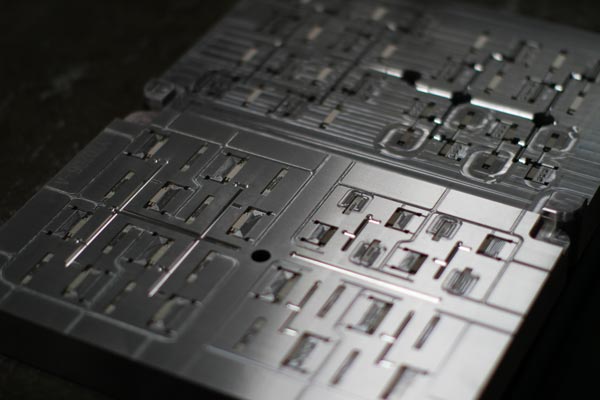

Thanks to its high hardness and excellent wear resistance, the tungsten carbide die can maintain die precision over a long period of use. In the manufacturing process of electronic products, such as the production of mobile phone batteries and electronic product casings, high – precision dies are the key to ensuring product quality. The tungsten carbide die can precisely meet this demand, ensuring that each product strictly conforms to the design – required precision standards and laying a solid foundation for the quality of electronic products.

Booster for High – Efficiency Production

In the electronic industry, production efficiency directly determines the market response speed and economic benefits of enterprises. The high hardness and wear resistance of the tungsten carbide die reduce the downtime caused by frequent die replacement and extend the service life of the die, thus significantly improving production efficiency. In addition, the tungsten carbide die can withstand relatively high processing temperatures and pressures, ensuring the efficient and stable operation of the production process and winning valuable time and cost advantages for electronic enterprises.

Cost – Control Weapon

Although the initial investment in tungsten carbide die is relatively high, from the perspective of long – term operation, its long service life and low maintenance costs give it significant advantages in cost control. In the electronic industry, which is highly sensitive to costs, this characteristic of the tungsten carbide die undoubtedly provides strong support for enterprises to reduce production costs and increase profit margins.

Expander of Diverse Applications

The application fields of tungsten carbide die are extremely wide. It is not only used in the manufacturing of casings and internal structural parts of electronic products but also plays an important role in cutting tools, measuring tools, and stretching dies. This diverse application pattern provides a broader market space and development prospects for the tungsten carbide die in the electronic industry and offers strong support for the diversified production of electronic enterprises.

IV. The Future Development Trends of Tungsten Carbide Die

With the continuous innovation of technology and the vigorous development of the electronic industry, the tungsten carbide die will face more challenges and opportunities. On the one hand, the continuous emergence of new materials and new technologies will bring further improvement space for the manufacturing process and material properties of the tungsten carbide die, driving it towards higher precision and higher efficiency. On the other hand, the continuously increasing requirements of electronic products for precision and quality will prompt the tungsten carbide die to pay more attention to meeting the personalized and diversified needs of products while maintaining its existing advantages to adapt to the rapid changes in the market.

V. Schlussfolgerung

In conclusion, the tungsten carbide die, with its significant advantages of high precision, strong wear resistance, and high efficiency, plays a pivotal role in the electronic industry. It not only provides reliable guarantees for the quality and precision of electronic products but also creates huge economic benefits for electronic enterprises by reducing production costs and improving production efficiency. Looking ahead, with the continuous progress of technology and the continuous evolution of market demands, we have every reason to believe that the tungsten carbide die will play an even more crucial role in the electronic industry and lead the electronic industry towards a more brilliant future.

However, we should also be clearly aware that the manufacturing and application of the tungsten carbide die still face many challenges. How to further improve the precision and stability of the die, extend its service life, reduce manufacturing costs, and meet diversified product demands are still the key directions for future research and development. Therefore, we need to continuously increase investment in technological research and development and innovation, promote the continuous upgrading and progress of the tungsten carbide die industry, and better meet the development needs of the electronic industry.

At the same time, against the backdrop of increasing global environmental awareness and growing calls for resource conservation, the environmental protection and sustainability of the tungsten carbide die have become the focus of industry attention. In the future, we need to actively explore environmentally friendly materials and green manufacturing processes while ensuring the performance of the die, promoting the tungsten carbide die to develop in a more environmentally friendly and sustainable direction and contributing to the green transformation of the electronic industry.

In addition, with the in – depth advancement of intelligent manufacturing and Industry 4.0, the intelligent manufacturing and digital management of the tungsten carbide die have become an important trend in the development of the industry. By introducing advanced sensors, control systems, and information technology, we can realize the automation, intelligence, and traceability of the die manufacturing process, further improving the manufacturing efficiency and quality level of the tungsten carbide die and providing stronger support for the high – quality development of the electronic industry.

In short, the application characteristics of the tungsten carbide die in the electronic industry highlight its unique advantages and huge potential. Facing the rapid development and diversified needs of the electronic industry in the future, we need to unswervingly strengthen technological research and development and innovation investment, promote the transformation, upgrading, and sustainable development of the tungsten carbide die industry, and contribute greater wisdom and strength to the prosperity and progress of the electronic industry.