How to Ensure the Precision Stability of Tungsten Carbide Dies After Long-Term Use

In the thriving manufacturing industry, tungsten carbide dies play a pivotal role as essential tools in the production process. The precision stability of these dies is akin to the foundation […]

In the thriving manufacturing industry, tungsten carbide dies play a pivotal role as essential tools in the production process. The precision stability of these dies is akin to the foundation of a building, directly determining the quality of products and the efficiency of production. However, during long-term use, various factors can cause the precision of tungsten carbide dies to change, thereby adversely affecting the machining accuracy and performance of products. Therefore, how to ensure the precision stability of tungsten carbide dies after long-term use has become a critical issue that the manufacturing industry needs to address urgently. This article will delve into effective strategies for ensuring the precision stability of tungsten carbide dies from multiple dimensions, including material selection and optimization, manufacturing process optimization, use and maintenance, as well as technological innovation and research and development.

Material Selection and Optimization: Laying the Foundation for Precision Stability

Careful Selection of High-Quality Tungsten Carbide Materials

Tungsten carbide materials are widely used in die manufacturing due to their high hardness, excellent wear resistance, and high heat resistance. However, different grades of tungsten carbide materials exhibit significant differences in performance. To ensure the precision stability of dies, it is necessary to select high-quality tungsten carbide materials with high purity, uniform microstructure, and superior mechanical properties. Additionally, based on the actual use conditions and specific requirements of the dies, the appropriate grade of tungsten carbide should be chosen to meet the stringent demands for hardness, wear resistance, and heat resistance. For example, when manufacturing high-precision and highly wear-resistant stamping dies, a specific grade of tungsten carbide with high hardness and excellent wear resistance should be selected to ensure that the dies do not wear or deform easily during long-term use, thereby maintaining precision stability.

Unser Fabrikgeschäft: Hartmetallteile, Formteile, medizinische Spritzgussformen, Präzisionsspritzgussformen, Teflon-PFA-Spritzguss, PFA-Rohrverschraubungen. E-Mail: [email protected],whatsapp:+8613302615729.

Precise Control of Material Heat Treatment Processes

Heat treatment is a crucial step in the manufacturing process of tungsten carbide dies, having a profound impact on material properties. A reasonable heat treatment process can improve the microstructure of tungsten carbide materials, significantly enhancing their hardness and wear resistance. Simultaneously, it can effectively eliminate residual stresses and internal defects in the materials, providing a solid guarantee for the precision stability of the dies. Therefore, during the manufacturing process, it is essential to strictly and precisely control the heat treatment process parameters, such as heating temperature, holding time, and cooling rate, to ensure the stability of material properties. For instance, adopting vacuum heat treatment technology can prevent oxidation and decarburization of the materials during the heat treatment process, further improving the quality and precision stability of the dies.

Manufacturing Process Optimization: Refining the Details of Precision Stability

Meticulous Application of Precise Machining Processes

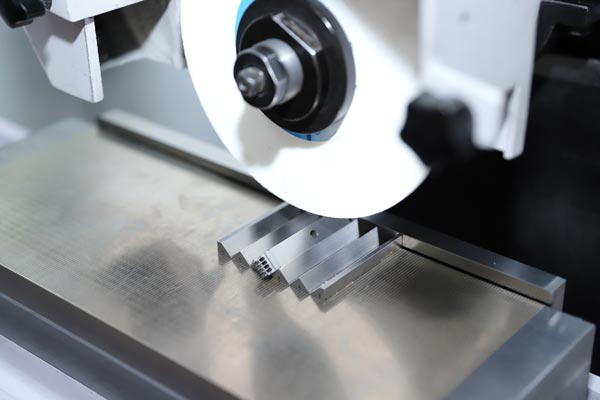

The precision of the machining process directly affects the precision stability of tungsten carbide dies. During the manufacturing process, high-precision machining equipment and advanced process methods, such as CNC machining and wire cutting, should be employed to ensure that the dimensional accuracy and shape accuracy of the dies meet extremely high standards. At the same time, the cutting parameters and tool selection during the machining process should be carefully optimized to minimize deformation and errors. For example, in CNC machining, by precisely setting parameters such as cutting speed, feed rate, and cutting depth, as well as selecting appropriate tool materials and tool geometries, the machining accuracy can be effectively improved, ensuring the precision stability of the dies.

Ingenious Design of Rational Structures

The structural design of dies also plays a vital role in precision stability. During the design process, it is necessary to fully consider the use conditions and requirements of the dies, rationally arrange the various parts of the dies to avoid stress concentration and deformation. Meanwhile, rational guiding mechanisms and positioning methods should be adopted to ensure that the dies remain stable and accurately positioned during use, thereby improving the precision stability of the dies. For example, designing a die structure with precision guide posts and locating pins can enable the dies to align accurately during the opening and closing processes, reducing errors caused by inaccurate positioning and ensuring the machining accuracy of products.

Rigorous Quality Inspection

Quality inspection is an important means of ensuring the precision stability of tungsten carbide dies. During the manufacturing process, strict dimensional and shape inspections should be conducted on each part of the dies using advanced inspection equipment and precise measuring tools to ensure that the precision of the dies meets the design requirements. Simultaneously, comprehensive inspections of the hardness, wear resistance, and other properties of the dies should be carried out using professional inspection instruments and methods to assess whether the performance of the dies is stable and reliable. For example, using a hardness tester to measure the hardness of the dies and a wear testing machine to test the wear resistance of the dies. Only when all inspection indicators meet the standards can the dies be put into use, thereby ensuring the quality of products.

Use and Maintenance: Caring for the Normal State of Precision Stability

Adherence to Proper Use Methods

Proper use methods are the key to ensuring the precision stability of tungsten carbide dies. During use, it is essential to strictly follow the die’s instruction manual and operating procedures, avoiding overloading and improper operations. At the same time, attention should be paid to the lubrication and cooling of the dies, and appropriate lubricants and cooling methods should be selected to reduce thermal deformation and wear of the dies during work. For example, during high-speed stamping die operations, an appropriate amount of lubricating oil should be added regularly to ensure good lubrication between the moving parts of the dies, reducing friction resistance. Meanwhile, an effective cooling device should be used to promptly remove the heat generated by the dies, preventing thermal deformation of the dies due to high temperatures and affecting precision stability.

Persistence in Regular Maintenance

Regular maintenance is an important measure to ensure the precision stability of tungsten carbide dies. During use, a detailed maintenance plan should be formulated, and the dies should be cleaned, inspected, and repaired regularly. The surface of the dies should be promptly cleaned of dirt and impurities, and each part of the dies should be inspected for wear, deformation, and other problems. Once any issues are detected, immediate repair or replacement should be carried out. At the same time, the lubrication system and cooling system of the dies should be carefully maintained to ensure their normal operation. For example, regularly replacing the lubricating oil and cooling fluid, cleaning the pipes and filters of the lubrication and cooling systems, ensuring good lubrication and cooling effects, extending the service life of the dies, and maintaining precision stability.

Orderly Arrangement of Rational Storage Methods

Rational storage methods also have a non-negligible impact on the precision stability of tungsten carbide dies. During storage, the dies should be placed in a dry, well-ventilated, and dust-free environment to prevent the dies from getting damp, corroded, and contaminated. Meanwhile, the dies should be classified, labeled, and stored separately to prevent collisions and damage between the dies. For example, custom-made storage racks can be used for the dies, with different types of dies placed on different shelves. Clear model and specification information should be marked on the dies for easy searching and management, ensuring that the dies remain in good condition during storage and providing a guarantee for subsequent use.

Technological Innovation and Research and Development: Leading the Future of Precision Stability

Active Exploration and Application of New Materials

With the rapid development of materials science, new tungsten carbide materials are constantly emerging. These new materials often possess superior properties, such as higher hardness, better wear resistance, and heat resistance, which can further improve the precision stability of tungsten carbide dies. Therefore, the manufacturing industry should closely monitor the development trends of new materials, actively collaborate with research institutions and material suppliers, and promptly apply new materials to die manufacturing. For example, developing new tungsten carbide materials with self-lubricating properties can reduce the lubrication requirements of the dies during use, lower the friction coefficient, improve the wear resistance and precision stability of the dies.

Continuous Research and Development of New Processes

The research and development of new processes are important ways to improve the precision stability of tungsten carbide dies. By developing new machining processes, heat treatment processes, etc., the precision and performance of the dies can be further enhanced, while reducing production costs and improving production efficiency. For example, developing laser machining processes, utilizing the high energy density and high precision characteristics of lasers to achieve micro-machining of tungsten carbide dies, improving the machining accuracy and surface quality of the dies. Developing new heat treatment processes, such as ion nitriding and laser quenching, can improve the surface properties of the dies, enhance their wear resistance and corrosion resistance, and strengthen precision stability.

Deep Integration and Application of Intelligent Technologies

With the increasing maturity of intelligent technologies, their applications in the die manufacturing field are becoming more and more widespread. By introducing intelligent technologies such as the Internet of Things, big data, and artificial intelligence, intelligent management and maintenance of dies can be achieved. For example, using the Internet of Things technology, sensors can be installed on the dies to monitor parameters such as the operating status, temperature, and pressure of the dies in real-time and transmit the data to a monitoring center. Through big data analysis technology, the monitored data can be deeply analyzed to predict potential faults and problems of the dies in advance and issue timely warnings. Using artificial intelligence technology, automatic diagnosis of die faults and intelligent generation of maintenance plans can be realized, improving the maintenance efficiency and quality of the dies, extending their service life, and enhancing precision stability and production efficiency.

Schlussfolgerung

In conclusion, ensuring the precision stability of tungsten carbide dies after long-term use is a systematic project that requires coordinated efforts from multiple aspects, including material selection and optimization, manufacturing process optimization, use and maintenance, as well as technological innovation and research and development. By carefully selecting high-quality tungsten carbide materials, precisely controlling heat treatment processes, optimizing manufacturing process details, standardizing the use and maintenance of dies, and actively introducing intelligent technologies, the precision stability and service life of tungsten carbide dies can be further improved, providing solid support for the high-quality development of the manufacturing industry and driving the manufacturing industry to new heights.

Verwandte Beiträge

- Protection Strategies for Tungsten Carbide Dies in High-Temperature and High-Humidity Environments

- The Environmental Impact of Packaging Materials for Tungsten Carbide Dies and Corresponding Countermeasures

- Exploration of Surface Treatment Technologies for Tungsten Carbide Dies

- Key Elements in the Design of Tungsten Carbide Die Frames