Tungsten Carbide Die Processing Safety Operating Procedures

I. Introduction In the field of die manufacturing, tungsten carbide dies are of great significance and have a wide range of applications due to their high hardness, excellent wear resistance, […]

I. Einleitung

In the field of die manufacturing, tungsten carbide dies are of great significance and have a wide range of applications due to their high hardness, excellent wear resistance, outstanding corrosion resistance, and good thermal stability. However, because of their extremely high hardness and significant brittleness, there are relatively high safety risks during the processing. Once improper operations occur, it may not only damage the dies and equipment but also pose a serious threat to the safety of processing personnel. To ensure the safe, efficient, and stable processing of tungsten carbide dies, this document has formulated a set of comprehensive and detailed safety operating procedures. These procedures aim to strictly standardize the processing operations, minimize the probability of accidents, and comprehensively safeguard the safety of personnel and equipment.

II. Safety Operating Procedures

(A) Pre-processing Preparations

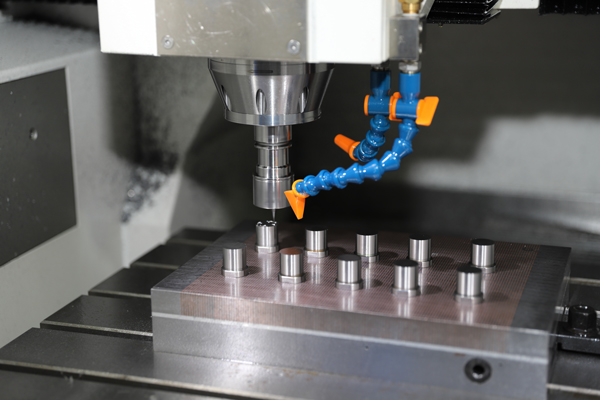

- Equipment Inspection: Before processing, it is essential to conduct a thorough inspection of the machine tools, fixtures, cutting tools, and other equipment. Check carefully for any damage, looseness, or electrical leakage to ensure that the equipment is in optimal operating condition and can provide reliable support for subsequent processing.

- Tool Selection and Installation: Select appropriate cutting tools based on the hardness of tungsten carbide and the specific processing requirements. The tools should not only be sharp enough but also have good durability. When installing the tools, make sure they are firmly and reliably installed to prevent the tools from falling off or breaking during the processing, which could lead to dangerous situations.

- Protective Equipment Wearing: Processing personnel must wear protective glasses, protective gloves, protective shoes, and other protective equipment as required. These protective items can effectively block flying objects, cutting fluids, and other substances from harming the human body during the processing, providing a safety barrier for the processing personnel.

(B) Processing Operations

- Fixierung des Werkstücks: Before processing, firmly fix the tungsten carbide workpiece on the fixture. Ensure that the workpiece is securely fixed to avoid safety accidents caused by workpiece looseness during processing. At the same time, control the clamping force of the fixture reasonably to prevent workpiece deformation due to excessive clamping force or workpiece damage due to insufficient clamping force.

- Cutting Parameter Control: During processing, set the cutting speed, cutting depth, feed rate, and other parameters reasonably according to the hardness of tungsten carbide and the processing requirements. Avoid excessive cutting force and high cutting temperature, which could cause tool damage or workpiece cracking, ensuring the smooth progress of the processing.

- Processing Monitoring: During processing, processing personnel should remain vigilant at all times and closely monitor the operating status of the machine tool, the use of cutting fluid, and the quality of the processed surface. If any abnormalities are detected, stop the machine immediately for inspection and troubleshoot the problems in a timely manner to ensure the safety and stability of the processing.

- No Hammering Allowed: Given the high hardness and significant brittleness of tungsten carbide, it is strictly prohibited to hammer the workpiece or cutting tools with metal hammers or other hard objects. Hammering can easily cause workpiece cracking, tool damage, and even irreparable damage to the machine tool.

- Maintaining a Safe Distance: During processing, processing personnel should maintain a sufficient safe distance from the machine tool, workpiece, and cutting tools. Avoid accidentally entering dangerous areas due to improper operations to ensure personal safety.

(C) Post-processing Handling

- Processing Quality Inspection: After processing, conduct a comprehensive and detailed inspection of the processed surface. Check for surface roughness, cracks, and other defects. If any problems are found, repair or reprocess them in a timely manner to ensure that the processing quality meets the requirements.

- Site Cleaning: After processing, promptly clean the cutting fluid, oil stains, and other debris on the machine tools, fixtures, cutting tools, and other equipment. Keep the equipment clean and tidy to create good conditions for the next processing.

- Wartung der Ausrüstung: Regularly maintain and service the machine tools, fixtures, cutting tools, and other equipment. Check whether the lubrication, fastening, electrical, and other parts of the equipment are working properly. If any abnormalities are found, repair or replace them in a timely manner to ensure that the equipment is always in good condition.

III. Safety Precautions

- Compliance with Operating Procedures: Processing personnel must strictly abide by these operating procedures and shall not arbitrarily change or omit any steps. If it is necessary to adjust the processing parameters or change the operation mode due to special circumstances, it must be approved by the relevant department and corresponding safety measures must be taken before implementation.

- Strengthening Training: Provide systematic safety training and technical training for newly recruited processing personnel. Enable them to fully understand the processing characteristics of tungsten carbide dies and the safety operating procedures, and improve their safety awareness and operational skills. At the same time, regularly conduct skill assessments and safety knowledge tests for processing personnel to ensure that they always have qualified work capabilities.

- Enhancing Safety Awareness: Processing personnel should always maintain a high level of safety awareness and closely monitor the operating status of the equipment and the processing quality during processing. If any abnormalities are found, stop the machine immediately for inspection and report to the superior in a timely manner to eliminate safety hazards at the bud stage.

- Strengthening Equipment Maintenance: Regularly maintain and service the machine tools, fixtures, cutting tools, and other equipment to ensure that the equipment is in good condition and meets the processing requirements. If any equipment abnormalities are found, repair or replace them in a timely manner to avoid safety accidents caused by equipment failures.

- Keeping the Site Clean: The processing site should be kept clean and orderly, avoiding the accumulation of debris and oil stains. Debris and oil stains not only affect the processing environment but may also cause safety hazards. At the same time, keep the passageways clear to facilitate personnel evacuation and equipment transportation.

IV. Schlussfolgerung

The safety operating procedures for tungsten carbide die processing are the cornerstone for ensuring the safe, efficient, and stable processing. By strictly adhering to these operating procedures and effectively implementing measures such as strengthening training, enhancing safety awareness, strengthening equipment maintenance, and keeping the site clean, the probability of accidents can be effectively reduced, providing solid protection for the safety of personnel and equipment. At the same time, these measures also help improve the processing quality and production efficiency, creating greater economic benefits for the enterprise and promoting its sustainable development in the fierce market competition.

Unser Fabrikgeschäft: Hartmetallteile, Formteile, medizinische Spritzgussformen, Präzisionsspritzgussformen, Teflon-PFA-Spritzguss, PFA-Rohrverschraubungen. E-Mail: [email protected],whatsapp:+8613302615729.