In – depth Analysis of the Manufacturing Process of Tungsten Carbide Dies

I. Introduction In the grand landscape of modern industrial production, tungsten carbide dies play a pivotal role due to their exceptional hardness, outstanding wear resistance, and excellent corrosion resistance. They […]

I. Introduzione

In the grand landscape of modern industrial production, tungsten carbide dies play a pivotal role due to their exceptional hardness, outstanding wear resistance, and excellent corrosion resistance. They serve as precise tools in industrial production, providing solid support for the molding and manufacturing of numerous products. To create high – quality tungsten carbide dies, their manufacturing process must undergo strict and meticulous control, leaving no room for error. This article will comprehensively and in – depth introduce the manufacturing process of tungsten carbide dies, covering key stages from material selection, design and drafting, processing and manufacturing to final inspection and debugging, helping readers gain an in – depth understanding of this core process.

II. Material Selection and Preparation: Laying the Foundation for Quality

The first step in the manufacturing of tungsten carbide dies is material selection, which is the crucial starting point that determines the performance and service life of the dies. Tungsten carbide, as a hard alloy, is usually formed by carefully mixing metal powders such as tungsten carbide and cobalt. Based on the specific uses and stringent requirements of the dies, it is necessary to precisely select tungsten carbide materials with different component ratios. The quality of the material is like the foundation of a building, directly related to the final performance and service life of the dies, so the importance of this step cannot be overstated.

La nostra attività in fabbrica: parti in metallo duro, parti di stampi, stampi a iniezione medicali, stampi a iniezione di precisione, stampaggio a iniezione di teflon PFA, raccordi per tubi PFA. e-mail: [email protected],whatsapp:+8613302615729.

During the material preparation stage, rigorous inspection and screening are essential. It is required to ensure that the raw materials are pure, free of impurities and defects, and strictly comply with manufacturing standards. In addition, pre – heating treatment of the materials is also a key step. This operation can effectively eliminate internal stresses and significantly improve the processing performance of the materials, laying a good foundation for subsequent manufacturing processes.

III. Design and Drafting: Drawing the Blueprint for Dies

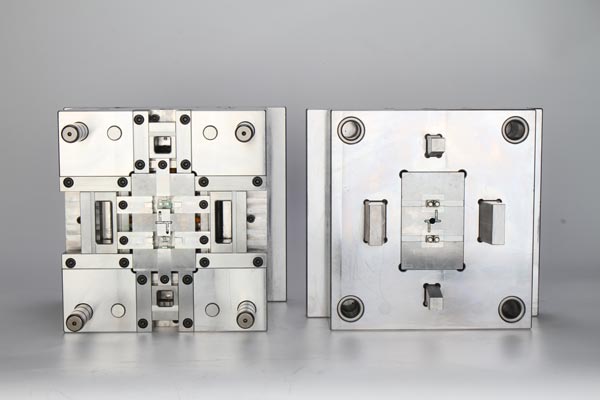

Once the material preparation is completed, the design and drafting stage begins. This is the cornerstone of die manufacturing, determining the final shape, precise dimensions, and high accuracy of the dies. Professional designers need to use advanced professional design software to carefully draw detailed die drawings according to the specific requirements of the products. The drawings should comprehensively cover all components of the dies, such as the cavity, core, cooling system, and ejection system, and ensure that the dimensions of each part are accurate without error, providing precise guidance for subsequent processing and manufacturing.

IV. Processing and Manufacturing: Carving Precision Dies

(A) Rough Machining: Shaping the Basic Outline

According to the design drawings, the rough machining stage is initiated first. The main task of this stage is to remove excess materials and initially form the basic shape of the dies. Common rough machining methods include milling, turning, and grinding. During the machining process, it is necessary to strictly control the machining parameters, such as cutting speed and feed rate, to ensure that the accuracy and surface quality of the dies meet the expected standards.

(B) Finish Machining: Enhancing Quality and Precision

After rough machining is completed, the finish machining stage follows. The core goal of this stage is to further improve the accuracy and surface finish of the dies, making them reach a higher quality level. Common finish machining methods include grinding, polishing, and electrochemical machining. This stage places extremely high demands on the skills of the operators, requiring them to have rich experience and superb craftsmanship to carve the dies into a near – perfect state.

(C) Heat Treatment: Strengthening Material Properties

After finish machining is completed, the dies need to undergo heat treatment. The purpose of heat treatment is to significantly improve the hardness and wear resistance of the dies by changing the material’s microstructure, thereby enhancing their service performance. Common heat treatment methods include quenching, tempering, and aging treatment. During the heat treatment process, it is crucial to precisely control key parameters such as temperature and time to ensure that the performance of the dies reaches the optimal state, providing a guarantee for the long – term stable use of the dies.

(D) Assembly and Debugging: Ensuring Smooth Operation

After heat treatment is completed, the assembly of the dies is carried out. During the assembly process, great attention should be paid to the fitting accuracy of each component to ensure that the dies do not experience jamming or looseness during operation, guaranteeing the stability and reliability of the dies. After assembly is completed, a comprehensive debugging of the dies is carried out to carefully check whether their operation is smooth and whether the positioning is accurate. If any problems are found, timely adjustments and repairs are required to ensure that the dies can be put into use in the best condition.

V. Inspection and Acceptance: Strictly Guarding the Quality Gate

After the manufacturing of the dies is completed, strict inspection and acceptance work is indispensable. The inspection content is extensive and detailed, mainly including dimensional accuracy, shape accuracy, positional accuracy, and surface quality. Common inspection methods include coordinate measurement, projector measurement, and microscopic inspection. Only products that have passed strict inspection and meet the high – quality standards can be delivered for use, ensuring that each tungsten carbide die meets the requirements.

VI. Summary and Prospects: Embracing an Innovative Future

The manufacturing process of tungsten carbide dies is a complex and precise systematic project, involving multiple stages and various advanced technologies. Through the detailed introduction in this article, it is believed that readers have gained a more in – depth and comprehensive understanding of the manufacturing process of tungsten carbide dies. With the continuous leap in technology and the rapid development of industry, the manufacturing technology of tungsten carbide dies is also continuously innovating and improving. In the future, we look forward with great anticipation to the wide application of more intelligent and automated manufacturing technologies in the production of tungsten carbide dies, further improving the quality and production efficiency of the dies and pushing the industry to new heights.

At the same time, to meet the constantly changing market demands and the increasingly diverse requirements of customers, tungsten carbide die manufacturing enterprises need to continuously strengthen technological research and development and talent cultivation, build a strong innovation team, and enhance their core competitiveness. By continuously optimizing the manufacturing process, improving product quality and service levels, they can provide customers with higher – quality and more efficient tungsten carbide die products and win market recognition and trust.

In addition, with the growing awareness of environmental protection, the manufacturing of tungsten carbide dies in the future also needs to pay more attention to environmental protection and sustainable development. Measures such as using environmentally friendly materials, optimizing production processes, reducing energy consumption, and minimizing waste emissions will become important trends in the development of the industry, promoting the transformation of the tungsten carbide die manufacturing industry towards a green and low – carbon direction.

VII. Conclusione

Tungsten carbide dies, as indispensable key tools in modern industrial production, the refinement and specialization of their manufacturing process are of vital importance for improving product quality and production efficiency. By gaining an in – depth understanding of the manufacturing process of tungsten carbide dies, we can better grasp their key technologies and quality control points and contribute to the continuous development and progress of the industry. It is hoped that this article can provide readers with useful references and inspirations, and work together to promote the continuous innovation and development of tungsten carbide die manufacturing technology, creating a better future.

Messaggi correlati

- Preventive Strategies for Fatigue Failure of Tungsten Carbide Dies

- Exploration of Strategies for Balancing Strength and Toughness in Tungsten Carbide Dies

- Corrosion Prevention Strategies and Practical Techniques for Tungsten Carbide Dies

- Comprehensive Analysis of Safety Precautions in the Use of Tungsten Carbide Dies