The Major Culprits Behind Tungsten Carbide Desoldering

Tungsten carbide, also commonly known as cemented carbide, is a formidable “heavyweight” in the alloy material world. It is meticulously crafted through powder metallurgy processes, combining hard compounds of refractory […]

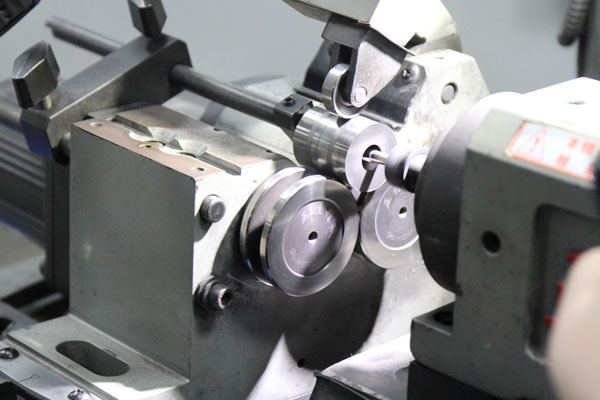

Tungsten carbide, also commonly known as cemented carbide, is a formidable “heavyweight” in the alloy material world. It is meticulously crafted through powder metallurgy processes, combining hard compounds of refractory metals with bonding metals. It boasts a series of remarkable properties, including ultra-high hardness, strong wear resistance, excellent strength and toughness, as well as good heat and corrosion resistance.

However, during the brazing process of tungsten carbide, desoldering often emerges as an unwelcome “intruder,” causing numerous troubles in production. So, what exactly are the factors that lead to desoldering of tungsten carbide? Let’s delve into it.

La nostra attività in fabbrica: parti in metallo duro, parti di stampi, stampi a iniezione medicali, stampi a iniezione di precisione, stampaggio a iniezione di teflon PFA, raccordi per tubi PFA. e-mail: [email protected],whatsapp:+8613302615729.

Brazing Surface Treatment: The Devil Is in the Details

Before the actual brazing, the brazing surface of tungsten carbide must undergo rigorous sandblasting or polishing treatment. This step is like a “deep cleaning” for the brazing surface, aiming to remove the oxide layer and dirt on it, allowing the brazing filler metal to wet better and thus enhancing the bonding strength of the weld seam. If the brazing surface is not adequately treated, the oxide layer will act as an invisible barrier, reducing the wettability of the brazing filler metal and weakening the bonding force of the weld seam, becoming an important “trigger” for desoldering.

Brazing Flux Selection and Usage: Choosing the Right “Helper” Is Key

Brazing flux plays a crucial role in the brazing process, acting like a diligent “cleaner” that helps remove oxides and impurities from the brazing surface, promoting the wetting and spreading of the brazing filler metal. However, if the brazing flux is improperly selected or used, desoldering may occur. For example, using raw borax with high moisture content as the brazing flux is like having an “incompetent helper” that cannot effectively perform the deoxidation function, resulting in the brazing filler metal failing to wet the brazed surface well and thus triggering desoldering.

Brazing Temperature Control: Precise Control Is the Key

The correct brazing temperature is the “golden key” to ensuring weld seam quality. Generally, the brazing temperature should be controlled within the range of 30 – 50℃ above the melting point of the brazing filler metal. Both excessively high and low temperatures can provide opportunities for desoldering. When the temperature is too high, oxidation may occur in the weld seam, like putting on a “fragile coat” for the weld seam, affecting its strength. On the other hand, when the temperature is too low, a thick weld seam will form, filled with pores and slag inclusions inside, which are like “time bombs” hidden in the weld seam and will also reduce its strength. In both cases, desoldering is likely to occur during grinding or use.

Slag Removal: Timely and Thorough Treatment Cannot Be Ignored

During the brazing process, timely and thorough slag removal is like a “big cleanup” for the weld seam and is of utmost importance. If slag removal is not timely or thorough, a large amount of brazing flux slag will remain in the weld seam. These slags are like “impurities” in the weld seam that will reduce its strength and lead to desoldering. Therefore, operators must always pay close attention to the slag removal situation during the brazing process to ensure the cleanliness of the weld seam.

Welding Current and Preheating: Auxiliary Links Also Matter

In addition to the four major reasons mentioned above, welding current and preheating are also the “hidden pushers” affecting the welding quality of tungsten carbide. Due to the high dissolution temperature of tungsten carbide, the welding current needs to be appropriately increased to ensure sufficient welding. Meanwhile, preheating the welded parts is like “warming up” the welding process, which helps improve the welding effect. If the current is too small or proper preheating is not carried out, the weld seam may not be firmly bonded, eventually leading to desoldering.

In conclusion, the main reasons for desoldering of tungsten carbide include improper brazing surface treatment, incorrect selection and usage of brazing flux, improper brazing temperature control, insufficient slag removal, as well as issues with welding current and preheating. To prevent desoldering, operators should strictly follow the brazing process requirements and ensure precise execution of each step. In addition, regular training and assessment of operators are also effective ways to improve welding quality. By continuously improving the process and strengthening personnel management, we can effectively reduce the risk of tungsten carbide desoldering and take the quality and reliability of products to a higher level.