Tungsten Carbide Die: A Comprehensive Guide to Daily Cleaning and Maintenance

In the thriving landscape of modern manufacturing, tungsten carbide dies stand out as indispensable tools due to their high hardness, excellent wear resistance, and outstanding mechanical properties. However, during continuous […]

In the thriving landscape of modern manufacturing, tungsten carbide dies stand out as indispensable tools due to their high hardness, excellent wear resistance, and outstanding mechanical properties. However, during continuous use, they are inevitably subject to various factors such as cutting heat, cutting force, and friction and wear. This leads to the accumulation of impurities like oil stains, chips, and rust on the die surface. These impurities act as hidden dangers, not only severely affecting the die’s machining accuracy and thus the product quality but also potentially accelerating the wear and damage of the die, shortening its service life. Therefore, the daily cleaning and maintenance of tungsten carbide dies are of paramount importance. Next, this article will elaborate on the significance, specific steps and methods, as well as relevant precautions of daily cleaning and maintenance for tungsten carbide dies.

I. The Importance of Daily Cleaning and Maintenance

The daily cleaning and maintenance of tungsten carbide dies are crucial for maintaining the die’s good condition and extending its service life. Firstly, through cleaning and maintenance, oil stains, chips, and other impurities on the die surface can be effectively removed, keeping the surface clean and thus significantly improving the die’s machining accuracy and ensuring the production of high-quality products. Secondly, during the cleaning and maintenance process, a comprehensive and detailed inspection of the die can be carried out, enabling the timely discovery of potential problems such as wear and cracks. Once these problems are identified, immediate repair or replacement measures can be taken to prevent further deterioration and ensure the die’s normal use. Finally, proper cleaning and maintenance can reduce the damage caused by cutting heat, cutting force, and other factors to the die, enhancing its durability and stability and providing strong support for the stable operation of production.

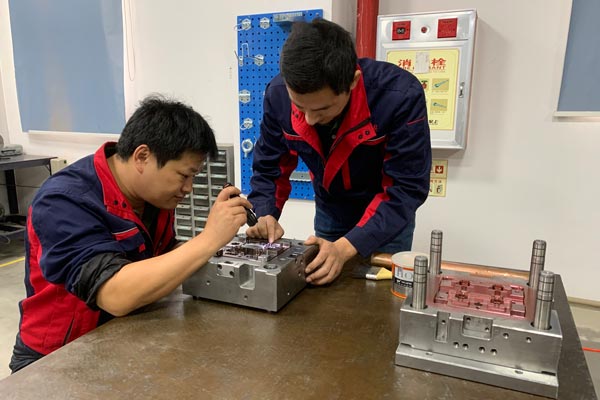

La nostra attività in fabbrica: parti in metallo duro, parti di stampi, stampi a iniezione medicali, stampi a iniezione di precisione, stampaggio a iniezione di teflon PFA, raccordi per tubi PFA. e-mail: [email protected],whatsapp:+8613302615729.

II. Steps and Methods of Daily Cleaning and Maintenance

(A) Preliminary Cleaning

Before conducting in-depth cleaning, it is essential to perform preliminary cleaning on the tungsten carbide die. Use a clean cloth or paper towel to gently wipe the die surface, removing large pieces of oil stains, chips, and other impurities attached to it. For some stubborn oil stains that are difficult to remove, a soft-bristled brush can be used for gentle scrubbing. However, it is crucial to avoid using hard-bristled brushes or metal tools to prevent leaving scratches on the die surface, which could affect its accuracy and appearance.

(B) Selecting the Appropriate Cleaning Agent

Selecting the right cleaning agent based on the degree of contamination on the die surface and its material properties is of great significance. An ideal cleaning agent should possess good detergency, low corrosivity, and environmental friendliness. For general oil stains and chips, water-based cleaning agents are a good choice as they can effectively remove dirt while being environmentally friendly. For heavy oil stains and rust, solvent-based cleaning agents can achieve better cleaning results. When using the cleaning agent, strictly follow the dilution ratio specified in the instructions to avoid overuse, which could lead to unnecessary waste or damage to the die.

(C) Soaking and Cleaning

Carefully place the tungsten carbide die into a cleaning tank and add an appropriate amount of cleaning agent to ensure that the die is fully immersed in the cleaning solution. Set a reasonable soaking time according to the performance of the cleaning agent and the degree of contamination on the die. During the soaking process, use a soft cloth or soft-bristled brush to gently wipe the die surface, helping to remove stubborn stains. After soaking, take the die out of the cleaning tank and rinse it thoroughly with clean water to ensure the complete removal of all residual cleaning agents and prevent corrosion.

(D) Drying Treatment

After cleaning, the tungsten carbide die must undergo drying treatment to prevent water residue from causing rust or corrosion. You can use a clean cloth or paper towel to gently dry the die surface or use a hot air gun or oven for drying. During the drying process, pay special attention to avoiding high-temperature baking or excessive friction on the die to prevent damage to its surface and affect its accuracy and service life.

(E) Inspection and Repair

During the cleaning and maintenance process, conduct a comprehensive and detailed inspection of the tungsten carbide die, covering aspects such as dimensional accuracy, surface finish, and edge sharpness. Once wear, cracks, or other potential problems are detected, take repair measures or replace the die in a timely manner. Repair methods include welding, grinding, and polishing, and the specific method should be selected reasonably according to the actual situation and degree of damage of the die to ensure its normal use after repair.

(F) Lubrication and Rust Prevention

To maintain the good condition of the tungsten carbide die, lubrication and rust prevention treatments are also necessary. Apply an appropriate amount of lubricating oil or grease to the sliding surfaces, mating surfaces, and other parts of the die to effectively reduce friction and wear and extend its service life. At the same time, spray a layer of rust inhibitor or rust-preventive oil on the die surface to form a protective film, preventing rust and corrosion and ensuring the die’s resistance to environmental factors during storage and use.

III. Precautions for Daily Cleaning and Maintenance

(A) Safe Operation

During the cleaning and maintenance of tungsten carbide dies, strictly adhere to safety operating procedures to ensure the safety of personnel and equipment. Avoid using flammable and explosive solvent-based cleaning agents and take effective fire prevention and explosion protection measures at the operation site. Meanwhile, operators should wear protective gloves, goggles, and other protective equipment to prevent cleaning agents from splashing into the eyes or skin and causing personal injury.

(B) Environmental Protection Requirements

When selecting cleaning agents, prioritize products with good environmental performance and avoid using cleaning agents containing harmful substances to reduce environmental pollution. Properly handle the wastewater, waste residues, and other wastes generated during the cleaning process in accordance with environmental protection requirements to ensure compliance with relevant environmental standards.

(C) Regular Cleaning and Maintenance

To ensure that the tungsten carbide die is always in good condition and extend its service life, establish a regular cleaning and maintenance plan. The specific cleaning and maintenance cycle can be reasonably determined based on factors such as the die’s usage frequency, working environment, and degree of contamination. Through regular cleaning and maintenance, potential problems with the die can be discovered and resolved in a timely manner, ensuring its normal operation.

(D) Maintenance Record Keeping

To facilitate the management and traceability of tungsten carbide dies, establish a comprehensive maintenance record. The record should include detailed information such as the cleaning and maintenance time, type and dosage of the cleaning agent, and cleaning effect. Through the maintenance record, the usage and maintenance history of the die can be clearly understood, potential problems can be discovered and resolved in a timely manner, and the die’s usage efficiency and service life can be improved.

IV. Conclusione

The daily cleaning and maintenance of tungsten carbide dies are the core aspects of ensuring their good condition and service life. By carefully selecting appropriate cleaning agents, adopting scientific and correct cleaning and maintenance methods, and strictly paying attention to relevant precautions, impurities such as oil stains and chips on the die surface can be effectively removed, maintaining the die’s cleanliness and machining accuracy. Meanwhile, adhering to regular cleaning and maintenance and keeping maintenance records can help discover and resolve potential problems with the die in a timely manner, significantly improving its usage efficiency and service life. Therefore, the manufacturing industry must attach great importance to the daily cleaning and maintenance of tungsten carbide dies, making it a key part of production management to ensure that the dies always perform at their best during the production process and provide strong support for the stable development of enterprises.

Messaggi correlati

- Selection and Usage Recommendations for Tungsten Carbide Die Cleaning Agents

- How to Maintain the Stability of Tungsten Carbide Dies in High-Speed Cutting

- Application and Effects of Wear-Resistant Coatings on Tungsten Carbide Dies

- Evaluation and Improvement Directions of the Environmental Performance of Tungsten Steel Molds