How to Comprehensively Ensure the Stability of Tungsten Carbide Dies under High Loads

In the grand landscape of industrial manufacturing, tungsten carbide dies shine like a brilliant gem, occupying a pivotal position. Especially in application scenarios with stringent requirements for high precision and […]

In the grand landscape of industrial manufacturing, tungsten carbide dies shine like a brilliant gem, occupying a pivotal position. Especially in application scenarios with stringent requirements for high precision and high wear resistance, tungsten carbide dies play an irreplaceable and crucial role. However, when operating under high-load conditions, ensuring the consistent stability of tungsten carbide dies has become a significant challenge for both manufacturers and users. Next, this article will delve into multiple dimensions to comprehensively analyze how to ensure the stability of tungsten carbide dies under high-load conditions through a series of technical means and management strategies.

I. Tungsten Carbide Dies: Characteristics Lay the Foundation for Applications

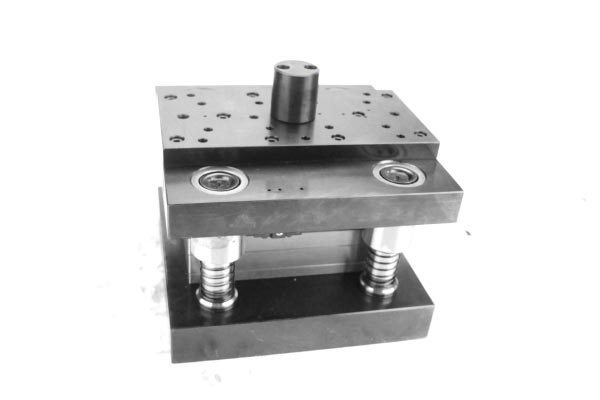

Tungsten carbide, also known as hard alloy, is renowned for its extremely high hardness and excellent wear resistance. In the field of die manufacturing, tungsten carbide is widely used to produce high-precision tools such as stamping dies, extrusion dies, and drawing dies. These dies need to withstand enormous pressure and friction forces when working under high loads, so the requirements for their stability are extremely demanding. The unique characteristics of tungsten carbide lay a solid foundation for the stable operation of dies under high-load environments.

당사의 공장 사업: 초경 부품, 금형 부품, 의료용 사출 금형, 정밀 사출 금형, 테플론 PFA 사출 성형, PFA 튜브 피팅. 이메일: [email protected],whatsapp:+8613302615729.

II. Design Optimization: Opening the Door to Stability

(A) Structural Rationality: The Wisdom of Stress Dispersion

The primary task in die design is to ensure structural rationality. A reasonable die structure is like a well-planned chess game, which can cleverly disperse the stresses during operation and effectively avoid stress concentration phenomena. In this way, the overall stability of the die is significantly improved, enabling it to operate steadily under high loads.

(B) Material Selection: The Secret to Performance Enhancement

Although tungsten carbide itself has excellent performance, in specific application scenarios, it is still necessary to further optimize its performance by adding other alloy elements. For example, adding elements to increase toughness and impact resistance can make the die more adaptable to complex working conditions, thereby ensuring its stability.

(C) Heat Treatment Process: The Magic of Internal Structure Optimization

Reasonable heat treatment processes, such as quenching and tempering, are a profound optimization of the internal structure of tungsten carbide dies. Through these processes, the mechanical properties and stability of the dies are further enhanced, providing strong support for high-load work.

III. Manufacturing Process Control: Double Guarantee of Precision and Quality

(A) Precision Machining: Precision Builds Stability

Advanced CNC machining technology is a powerful tool for ensuring the precision and surface quality of dies. High-precision dies can minimize friction and vibration during operation, acting like a “stability armor” for the dies, enabling them to maintain stable operation under high loads.

(B) Strict Quality Control: Standards Build Quality

Implementing strict quality inspection and control procedures during the manufacturing process is crucial. Every production link must strictly comply with preset standards and requirements, acting like a “safety lock” for the stability of the dies, ensuring the high quality and high stability of the final products.

IV. Surface Treatment and Coating Technologies: Double Improvement of Wear Resistance and Stability

(A) Surface Hardening Treatment: Strengthening Hardness and Wear Resistance

Surface hardening treatment technologies such as carburizing and nitriding can significantly enhance the surface hardness and wear resistance of dies. This technology is like building a solid “shield” on the surface of the dies, effectively extending their service life and improving their stability under high loads.

(B) Wear-Resistant Coatings: The Magical Overcoat of Ultra-Hard and Wear-Resistant Properties

Advanced coating technologies, such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), can form an ultra-hard and wear-resistant coating on the surface of dies. This coating not only greatly improves the wear resistance and corrosion resistance of the dies but also reduces the friction coefficient, providing additional protection for the stable operation of the dies under high loads.

V. Use and Maintenance: Details Determine the Success of Stability

(A) Standardized Operation: Standards Lead the Way to Stability

Formulating strict operating procedures to ensure that every step of die operation during use complies with standards is the key to avoiding die damage caused by improper operation. Standardized operation is like drawing a precise “map” for the stable operation of the dies, guiding users to move forward correctly.

(B) Regular Maintenance and Inspection: Early Detection and Resolution of Problems

Establishing a regular maintenance and inspection system can timely detect and deal with potential problems that may occur during die use, such as cracks and wear. This is like conducting regular “physical examinations” for the dies, nipping potential problems in the bud and ensuring their long-term stable operation.

(C) Reasonable Lubrication and Cooling: Dual Regulation of Temperature and Stress

During high-load operation, a reasonable lubrication and cooling system can effectively reduce the working temperature of the dies and minimize thermal stress and friction. This is like installing a “temperature control system” for the dies, enabling them to maintain an appropriate working state under high loads and improving their stability.

VI. Technological Innovation and R&D: Long-Term Driving Force for Stability Improvement

With the rapid development of science and technology, new materials and new processes are emerging continuously. Through continuous technological innovation and R&D, exploring die materials and manufacturing processes that are more suitable for high-load working environments is a long-term strategy for improving the stability of tungsten carbide dies. Only through continuous innovation can we remain invincible in the fierce market competition and inject a continuous stream of power into the stable operation of the dies.

VII. Case Analysis: The Path to Stability in Practice

Through specific case analysis, we can more intuitively understand how to ensure the stability of tungsten carbide dies in actual operations. For example, an automotive parts manufacturer, when using tungsten carbide stamping dies, significantly improved the stability and service life of the dies under high loads by optimizing die design, adopting advanced coating technologies, and combining strict manufacturing and quality control procedures. This successful case provides valuable practical experience for us and is worth learning from and promoting.

VIII. Conclusion and Outlook: A Promising Future on the Road to Stability

Ensuring the stability of tungsten carbide dies under high loads is a systematic project involving multiple links such as design, manufacturing, use, and maintenance. Only through comprehensive technical means and management strategies can we ensure that the dies can maintain excellent performance under harsh working environments. Looking ahead, with the continuous development of new materials and new technologies, we have reason to believe that the stability of tungsten carbide dies will be further improved, bringing higher efficiency and better-quality products to industrial manufacturing and opening a more glorious new chapter of stable development.

관련 게시물

- Selection Basis for Wear-Resistant Coating Materials of Tungsten Carbide Die

- How to Enhance the Performance of Tungsten Carbide Die through Heat Treatment

- Enhancing the Performance of Tungsten Carbide Die through Advanced Manufacturing Technologies

- The Impact of the Precision of Tungsten Carbide Die on Machining Quality