The “Regulation Code” for the Lifespan of Tungsten Carbide Dies

I. Introduction In the grand landscape of modern manufacturing, tungsten carbide dies shine like a brilliant pearl, playing an indispensable and crucial role. The length of their lifespan is akin […]

I. 소개

In the grand landscape of modern manufacturing, tungsten carbide dies shine like a brilliant pearl, playing an indispensable and crucial role. The length of their lifespan is akin to a weight on a delicate balance scale, directly influencing the level of production efficiency and the fluctuations in costs. Cutting parameters, as the core elements in the die machining process, are like a magical key, having a significant impact on the lifespan of tungsten carbide dies. This article will delve into the key cutting parameters such as cutting speed, feed rate, and cutting depth, thoroughly analyze their specific impacts on the lifespan of tungsten carbide dies, and put forward a series of practical optimization suggestions.

II. Cutting Parameters: The “Conducting Baton” of Machining

Cutting parameters, simply put, refer to the ingenious combination of parameters such as cutting speed, feed rate, and cutting depth during the cutting process. The selection of these parameters is by no means arbitrary; instead, it directly determines the efficiency and quality of the cutting process, and subsequently has a profound impact on the lifespan of tungsten carbide dies. Cutting speed refers to the distance that the cutting tool moves relative to the workpiece along its working direction per unit time during the cutting process. It is like the “tempo controller” of the cutting process. The feed rate is the amount of movement of the cutting tool relative to the workpiece in the feed direction during the cutting process, resembling the “step size” of cutting. Cutting depth is the depth to which the cutting tool cuts into the surface of the workpiece, akin to the “degree of penetration” of cutting.

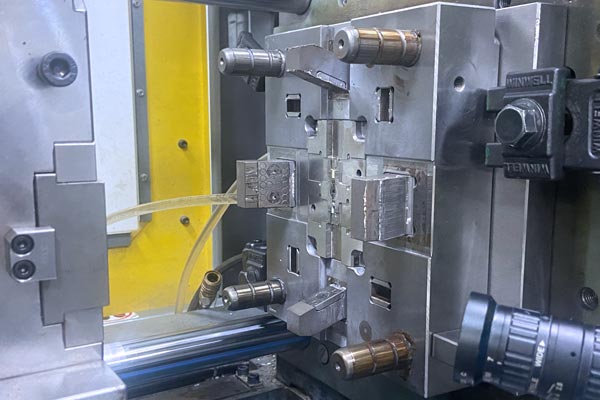

당사의 공장 사업: 초경 부품, 금형 부품, 의료용 사출 금형, 정밀 사출 금형, 테플론 PFA 사출 성형, PFA 튜브 피팅. 이메일: [email protected],whatsapp:+8613302615729.

III. Cutting Parameters: The “Double-Edged Sword” for Die Lifespan

(A) Cutting Speed: The Game of “Heat and Force” Behind Speed

Cutting speed is undoubtedly one of the important factors affecting the lifespan of tungsten carbide dies. When the cutting speed is excessively high, it is like igniting a “high-temperature fire” in the cutting process, causing the cutting temperature to rise sharply. This high temperature acts as a ruthless eroder, exacerbating the wear and fatigue of the die material, leaving the die “scarred” without realizing it. At the same time, an excessively high cutting speed also subjects the cutting tool to excessive stress, as if placing a heavy burden on it, which is highly likely to cause fractures or damage, putting the lifespan of the die in a precarious situation. Conversely, if the cutting speed is too low, although some problems related to high temperature and stress can be avoided, other issues may arise. In that case, the processing efficiency will drop significantly, as slow as a snail crawling, and the wear of the cutting tool may also increase, which is also not conducive to extending the lifespan of the die.

To extend the lifespan of tungsten carbide dies, it is crucial to reasonably control the cutting speed. Specifically, it is necessary to comprehensively consider various factors such as the hardness and toughness of the tungsten carbide material, the processing accuracy requirements, and the performance of the cutting tool, and carefully select an appropriate cutting speed. During actual machining, one can, like exploring a treasure trove, find the optimal cutting speed range through experiments and optimization methods.

(B) Feed Rate: The Trade-off between “Force and Heat” in Size

The feed rate is also a key factor affecting the lifespan of tungsten carbide dies. Its magnitude directly affects the cutting force and cutting heat during the cutting process. When the feed rate is too large, the cutting force will increase like a surging tide, launching a fierce attack on the die material and exacerbating its wear and fatigue. At the same time, an excessively large feed rate will also cause a significant increase in cutting heat, as if placing a “high-temperature shackle” on the die, further reducing its lifespan. Conversely, if the feed rate is too small, although the cutting force and cutting heat can be reduced, the processing efficiency will be greatly compromised, as difficult as walking through mud, increasing processing costs.

To optimize the impact of the feed rate on the lifespan of tungsten carbide dies, it is necessary to select an appropriate feed rate according to specific processing requirements and conditions, just like carefully blending a fine wine. During actual machining, the optimal feed rate range can also be found through experiments and optimization methods. In addition, advanced cutting technologies and tools such as high-speed cutting and precision grinding can be used, like adding a “protective shield” to the die lifespan, to reduce the impact of the feed rate on the die lifespan.

(C) Cutting Depth: The Consideration of “Vibration and Damage” in Depth

Cutting depth, which refers to the depth to which the cutting tool cuts into the surface of the workpiece, is also an important factor affecting the lifespan of tungsten carbide dies. An excessively large cutting depth will increase the cutting force and cutting heat, as if exerting a powerful “destructive force” on the die, leading to accelerated wear of the die material. At the same time, an excessively large cutting depth may also cause excessive vibration and impact of the cutting tool during the machining process, as if sounding an “alarm bell” on the die, further reducing its lifespan. Conversely, an excessively small cutting depth, although it can reduce the cutting force and cutting heat, will affect the processing efficiency, as restricted as sailing in shallow waters.

To optimize the impact of cutting depth on the lifespan of tungsten carbide dies, it is necessary to select an appropriate cutting depth according to specific processing requirements and conditions, just like carving an artwork. During actual machining, the optimal cutting depth range can be found through experiments and optimization methods. In addition, advanced cutting technologies and tools such as multi-axis simultaneous machining and laser cutting can be adopted, like opening an “innovation door” for the die lifespan, to reduce the impact of cutting depth on the die lifespan.

IV. Optimization Strategies: Safeguarding the Lifespan of Dies

(A) Comprehensive Consideration and Precise Combination

When selecting cutting parameters, one should not focus only on a single parameter but comprehensively consider the combined impact of factors such as cutting speed, feed rate, and cutting depth on the die lifespan, just like blending a colorful cocktail to find the optimal combination of cutting parameters.

(B) Skillful Selection of Tools to Enhance Efficiency

According to processing requirements and conditions, carefully select appropriate cutting tools such as cemented carbide tools and ceramic tools, just like equipping soldiers with sophisticated weapons, to improve cutting efficiency and reduce die wear.

(C) Effective Use of Cutting Fluid for Cooling and Lubrication

Cutting fluid plays an important role in the cutting process. It acts as a considerate “little helper”, providing cooling, lubrication, and cleaning functions. It can effectively reduce the cutting temperature and cutting force and minimize die wear. Therefore, cutting fluid should be fully used during the machining process to allow the die to work in a comfortable environment.

(D) Regular Maintenance to Revitalize

Regularly maintain and service the die, such as cleaning, grinding, and coating, just like performing regular maintenance on a car, to keep the die in good condition and extend its lifespan.

(E) Strengthening Training for Standardized Operations

The technical level and operational norms of operators also have a significant impact on the die lifespan. Therefore, it is necessary to strengthen the training and management of operators, improve their operational skills and awareness, and make every operator a “guardian” of the die lifespan.

V. 결론

Cutting parameters are undoubtedly one of the key factors affecting the lifespan of tungsten carbide dies. By reasonably controlling cutting parameters such as cutting speed, feed rate, and cutting depth, it is like injecting a “source of vitality” into the die, which can significantly reduce the wear and fatigue of the die and extend its lifespan. During actual machining, it is necessary to select an appropriate combination of cutting parameters according to specific processing requirements and conditions, like a skilled commander, and take effective measures to optimize the cutting process and improve the die lifespan, allowing tungsten carbide dies to shine even more brilliantly on the stage of modern manufacturing.