Unveiling the Mystery of Tungsten Carbide Product Deformation and Unlocking the Path to Quality Improvement

In the vast realm of the manufacturing industry, tungsten carbide shines like a brilliant star. With its high hardness, excellent wear resistance, outstanding heat resistance, and strong corrosion resistance, it […]

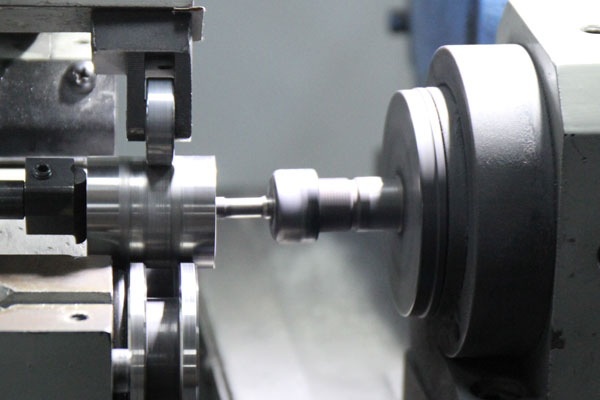

In the vast realm of the manufacturing industry, tungsten carbide shines like a brilliant star. With its high hardness, excellent wear resistance, outstanding heat resistance, and strong corrosion resistance, it finds extensive applications in numerous fields such as cutting tools, molds, and wear – resistant parts. However, in the actual production process, tungsten carbide products occasionally encounter the problem of deformation. This not only casts a shadow over the appearance quality of the products but may also hurt their service performance. Next, let’s delve deeply into the causes of tungsten carbide product deformation to provide solutions for manufacturers.

A Full – scale Analysis of the Production Process of Tungsten Carbide Products

To thoroughly understand the causes of tungsten carbide product deformation, we first need to be well – acquainted with its production process. The production of tungsten carbide is akin to a precise “chemical magic”, mainly encompassing several key steps: powder preparation, pressing molding, sintering, and subsequent processing.

당사의 공장 사업: 초경 부품, 금형 부품, 의료용 사출 금형, 정밀 사출 금형, 테플론 PFA 사출 성형, PFA 튜브 피팅. 이메일: [email protected],whatsapp:+8613302615729.

In the powder preparation stage, through delicate processes such as mixing and ball – milling, the raw material powders of tungsten, cobalt, and carbon are skillfully blended to prepare uniform alloy powders. This is like laying the foundation for building a mansion. During the pressing molding process, the well – prepared alloy powders are placed into a mold. With the help of pressure, they are transformed into the desired shape, much like a sculptor giving initial form to the material. The sintering step involves placing the pressed and molded tungsten carbide billet into a high – temperature “furnace” for heat treatment, prompting the internal particles to combine tightly and form a dense alloy. This process is similar to turning loose sand grains into a solid rock. Subsequent processing includes operations such as grinding and polishing, which are like giving the product a final “beauty treatment” so that it can be presented in a perfect state.

A Comprehensive Revelation of the Causes of Tungsten Carbide Product Deformation

Material Factors: The “Hidden Culprits” Behind the Scenes

- Uneven Raw Material Composition: If the composition of the raw materials for tungsten carbide products is uneven, it is like throwing a stone into a calm lake, which will trigger stress differences within the product. These stress differences are like a time bomb.

- Inappropriate Powder Particle Size: The particle size of the powder has a profound impact on the performance of tungsten carbide products. If the particle size is too large, there will be voids inside the product, just like a building with many hollow parts, which will greatly reduce its strength. If the particle size is too small, uneven shrinkage will occur during sintering, similar to an uncoordinated body development, which is highly likely to cause deformation.

- Excessive Impurity Content: Impurities in the raw materials, such as oxygen and sulfur, once their content is too high, will act like “troublemakers”, affecting the sintering performance and mechanical properties of tungsten carbide, thus significantly increasing the risk of product deformation.

Production Process Factors: The “Loss of Control” in Key Links

- Uneven Pressing Molding Pressure: During the pressing molding process, if there are defects in the mold design or improper operation, the pressure exerted on the tungsten carbide billet will be uneven. This is like building a house where different parts receive different pressures. During the sintering process, deformation is almost inevitable.

- Improper Control of Sintering Temperature and Time: Sintering temperature and time are like the “double – edged swords” that affect the performance of tungsten carbide products. If the sintering temperature is too high or the time is too long, the internal grains of the product will become coarse, just like the branches of a tree becoming too thick, which will reduce its toughness. If the sintering temperature is too low or the time is too short, there may be un – sintered powder particles inside the product, similar to an unfinished part of a building, which will also greatly reduce its strength. All of these lay hidden dangers for deformation.

- Stress Concentration in Subsequent Processing: During subsequent processing operations such as grinding and polishing, if the operation is not standardized or the tool selection is unreasonable, local stress concentration will occur in the product. This is like applying an excessive force to a rope, which is likely to cause deformation.

Usage Environment Factors: The “Tests” from the External Environment

- Temperature Influence: When tungsten carbide products are in use, if they are exposed to high – temperature or large – temperature – difference environments, thermal stress will be generated inside them, just like a piece of metal deforming under alternating cold and heat, thus causing deformation.

- Mechanical Stress Action: During usage processes such as cutting and stamping, tungsten carbide products will bear large mechanical stresses. Once the stress exceeds their bearing capacity, the products will deform or even crack, similar to a bridge collapsing under an excessive load.

- Corrosion Effect: Although tungsten carbide has excellent corrosion resistance, in some special environments, it may still be subject to corrosion. Corrosion will increase the surface roughness and reduce the thickness of the product, much like a piece of metal being slowly eroded, and then trigger deformation.

“Strategies” to Prevent Tungsten Carbide Product Deformation

Optimizing Raw Material Formulas and Powder Preparation Processes

By carefully optimizing the raw material formulas and powder preparation processes, we can ensure that the raw material composition is uniform, the powder particle size is appropriate, and the impurity content is extremely low, laying a solid foundation for the production of high – quality tungsten carbide products.

Improving Production Processes and Equipment

Optimizing the mold design, improving the pressing molding accuracy, precisely controlling the sintering temperature and time and other process parameters will enable the tungsten carbide products to receive uniform pressure and heat treatment during the production process, thus reducing the risk of deformation. At the same time, actively adopting advanced production equipment and technical means can improve production efficiency and product quality.

Strengthening Subsequent Processing Management

During subsequent processing, we should strengthen operation management, reasonably select tools and abrasives, and strictly control parameters such as processing speed and pressure to avoid local stress concentration and deformation phenomena in the products.

Using and Maintaining Products Reasonably

When using tungsten carbide products, we should try our best to avoid adverse factors such as high temperature, large temperature differences, and excessive mechanical stresses. At the same time, we should regularly maintain and inspect the products, promptly discover and deal with potential problems and hidden dangers to ensure the stability and reliability of the products.

Enhancing Product Inspection Levels

By using advanced inspection equipment and technical means, we can conduct strict inspections and quality control on tungsten carbide products to ensure that their performance and quality meet the requirements. For products with deformation problems, we should conduct in – depth cause analysis and treatment to prevent similar problems from occurring again.

결론

The deformation of tungsten carbide products is a complex issue involving multiple aspects such as materials, processes, and usage environments. To reduce the risk of tungsten carbide product deformation, we need to take comprehensive measures from multiple dimensions, including raw material formulas, production processes, subsequent processing management, and product usage and maintenance. At the same time, manufacturers also need to strengthen technological research and development and talent cultivation to continuously improve product quality and competitiveness and stand firm in the fiercely competitive market.