Processing of Tungsten Carbide Mold Components

The processing of tungsten carbide mold components is akin to a precise artistic creation, a complex and meticulous process. To achieve superior processing results, it is necessary to comprehensively consider […]

The processing of tungsten carbide mold components is akin to a precise artistic creation, a complex and meticulous process. To achieve superior processing results, it is necessary to comprehensively consider and deeply optimize multiple key dimensions, including material selection, processing techniques, equipment selection, quality control, and technological innovation. This article will delve into how to realize high-quality processing of tungsten carbide mold components, providing practical guidance and suggestions for practitioners.

1. High-Quality Materials: The Cornerstone of Processing Results

The processing result of tungsten carbide mold components is primarily determined by the quality of raw materials. Selecting high-quality tungsten carbide materials is the solid foundation for ensuring stable processing results. Premium tungsten carbide should possess uniform chemical composition, just like a perfectly formulated chemical agent with precise proportions of each component. It should also have fine grain structures, akin to tightly and uniformly arranged fine sand particles, along with good mechanical properties that enable stable performance under stress.

당사의 공장 사업: 초경 부품, 금형 부품, 의료용 사출 금형, 정밀 사출 금형, 테플론 PFA 사출 성형, PFA 튜브 피팅. 이메일: [email protected],whatsapp:+8613302615729.

Moreover, the hardness and toughness of the material need to strike a perfect balance. Excessive hardness can lead to cracks during processing, similar to brittle glass, while excessive toughness may result in insufficient wear resistance, affecting the service life of the mold components. Simultaneously, the thermal stability and corrosion resistance of the material cannot be overlooked. During the use of mold components, thermal stability ensures their stable performance under high-temperature conditions, and corrosion resistance enables them to withstand the erosion of various chemical substances, thereby maintaining consistent performance. Establishing a long-term and stable cooperative relationship with high-quality suppliers is like adding an extra layer of “insurance” to the raw material supply, ensuring a stable supply and controllable quality of raw materials, which provides a solid guarantee for the processing result.

2. Fine Processing Techniques: The Sharp Edge for Carving Processing Quality

In the processing of tungsten carbide mold components, fine processing techniques are the key to enhancing quality. Firstly, precise drawing design and process planning are of utmost importance. This is like drawing an accurate map that provides clear directions for each processing step, ensuring that every step strictly adheres to the design requirements.

During the processing, precise control over parameters such as cutting depth, feed rate, and cutting speed is crucial, just as a chef controls the heat to ensure the perfect taste of a dish. Over-cutting may cause dimensional deviations in the mold components, while under-cutting may fail to achieve the expected processing accuracy. Adopting advanced processing techniques, such as high-speed cutting and precision grinding, is like injecting a “high-efficiency catalyst” into the processing. High-speed cutting can quickly remove excess material and improve processing efficiency, while precision grinding can achieve extremely high surface accuracy, effectively reducing thermal deformation and residual stress during processing, thereby enhancing the precision and stability of the mold components.

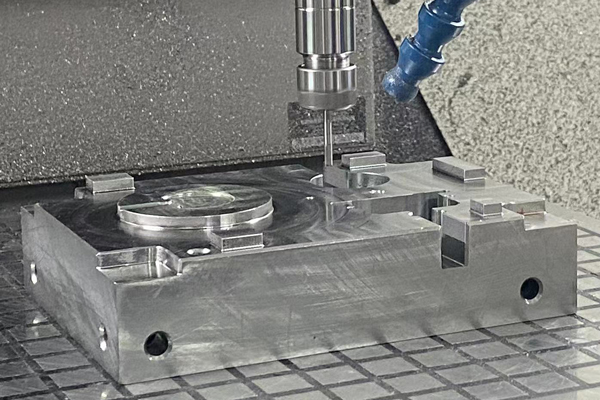

3. Suitable Equipment: The Backing for Ensuring Processing Accuracy

Selecting suitable processing equipment is the solid backing for improving the processing result of tungsten carbide mold components. High-performance CNC machine tools and precision grinding machines, like skilled craftsmen, can provide higher processing accuracy and stability. When choosing equipment, it is necessary to comprehensively consider factors such as processing range, accuracy, stability, and maintenance. The processing range determines whether the equipment can meet the processing requirements of mold components of different sizes and shapes. Accuracy is the core indicator for evaluating equipment performance and directly affects the quality of mold components. Stability ensures that the equipment maintains consistent performance during long-term operation. Good maintenance can extend the service life of the equipment and reduce the failure rate.

Regular maintenance and upkeep of the equipment are like conducting “health check-ups” for it. Timely detection and resolution of potential problems, maintaining the equipment in good condition, can not only improve processing efficiency but also ensure the stability of processing quality.

4. Strict Quality Inspection: The Checkpoint for Controlling Processing Quality

Strict quality control is the key checkpoint for ensuring the processing result of tungsten carbide mold components. During the processing, regular quality inspections are essential. This includes comprehensive checks on dimensional accuracy, shape accuracy, and positional accuracy, similar to a thorough “physical examination” for the mold components, leaving no room for even the slightest deviation.

Using advanced inspection equipment and precise measurement methods is like equipping quality inspection with “sharp eyes” that can promptly detect and correct deviations and errors during processing. Establishing a comprehensive quality management system is like constructing a rigorous “rule system” for quality control. Formulating detailed processing procedures, operation specifications, and inspection standards ensures that every processing link follows established rules and has a basis for reference. At the same time, regular training and assessment of processing personnel can improve their skill levels and quality awareness, acting as a high-quality “guard team” for quality control and ensuring the processing result from the source.

5. Technological Innovation: The Driving Force for Leading Processing Development

With the rapid development of science and technology, new processing techniques and equipment are constantly emerging. To keep the processing result of tungsten carbide mold components at the forefront of the industry, enterprises need to have keen market insight and forward-looking strategic vision. They should continuously monitor industry trends and technological development trends and actively introduce and apply new technologies and equipment.

Technological innovation and equipment upgrading are like injecting a continuous stream of “fresh blood” into the processing, further improving processing accuracy, efficiency, and stability, and meeting the ever-changing market demands. For example, adopting new coating techniques can significantly enhance the wear resistance and service life of cutting tools, while introducing intelligent processing systems can realize the automation and intelligent control of the processing, reducing the impact of human factors on processing quality.

6. Summary

To significantly improve the processing result of tungsten carbide mold components, it is necessary to take coordinated and comprehensive measures in multiple aspects, including material selection, processing techniques, equipment selection, quality control, and technological innovation. By carefully selecting high-quality materials, strictly adhering to fine processing techniques, reasonably selecting suitable equipment, comprehensively implementing strict quality control, and continuously promoting technological innovation, enterprises can significantly enhance the processing result of tungsten carbide mold components, stand out in the fierce market competition, and lay a solid foundation for their sustainable development.