-

-

In – depth Analysis of the Manufacturing Process of Tungsten Carbide Dies

I. Introduction In the grand landscape of modern industrial production, tungsten carbide dies play a pivotal role due to their exceptional hardness, outstanding wear resistance, and excellent corrosion resistance. They […]

More

tungsten carbide

-

-

Preventive Strategies for Fatigue Failure of Tungsten Carbide Dies

I. Introduction Tungsten carbide dies are widely applied in various cold and hot working processes due to their high hardness and excellent wear resistance. However, as the service time extends, […]

More

-

-

Exploration of Strategies for Balancing Strength and Toughness in Tungsten Carbide Dies

In the vast landscape of industrial production, tungsten carbide dies hold a pivotal position due to their exceptional hardness and wear resistance, finding widespread applications across numerous manufacturing sectors. However, […]

More

-

-

Corrosion Prevention Strategies and Practical Techniques for Tungsten Carbide Dies

In the crucial links of industrial production, tungsten carbide dies hold an irreplaceable and significant position due to their extraordinary hardness, excellent wear resistance, and outstanding stability. However, even with […]

More

-

-

Comprehensive Analysis of Safety Precautions in the Use of Tungsten Carbide Dies

In the field of industrial production, especially in the electronics industry, tungsten carbide dies play a pivotal role due to their high hardness, excellent wear resistance, and good thermal stability. […]

More

-

-

Application Characteristics and Prospects of Tungsten Carbide Die in the Electronic Industry

In the era when technology is surging forward with great momentum, the electronic industry is undergoing unprecedented transformation and rapid development. There is an ever – increasing demand for high […]

More

-

-

Analysis of Causes and Solutions for Tungsten Carbide Die Sticking

In the field of metal processing, tungsten carbide dies are indispensable key tools in numerous production processes due to their exceptional hardness and excellent wear resistance, widely applied in various […]

More

-

-

High-Precision Inspection System for Tungsten Carbide Dies

【Introduction】In the fields of precision manufacturing and stamping, tungsten carbide dies have become core process equipment due to their superior hardness and wear resistance. However, even a micron-level deviation in die precision […]

More

-

-

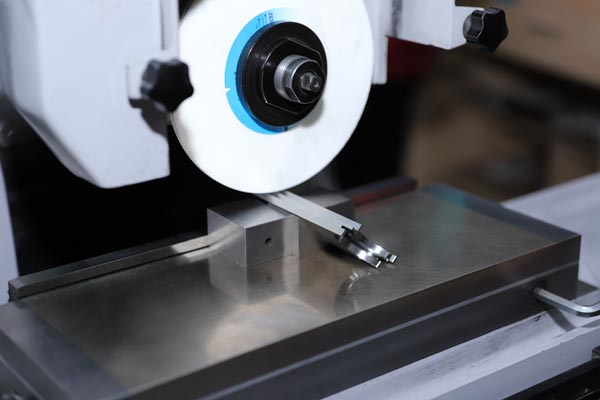

How to Control the Cutting Force of Tungsten Carbide Die?

In the field of die manufacturing, tungsten carbide die is the preferred material for many enterprises due to its high hardness, high strength, and excellent wear resistance. However, the high […]

More

-

-

Exploring the Causes and Prevention Measures of Deformation in Tungsten Carbide Dies

In the grand landscape of industrial production, tungsten carbide dies, with their high strength, high hardness, and excellent wear resistance, occupy a pivotal position and are widely applied in numerous […]

More