Tungsten carbide nozzle

Low-priced China manufacturer buy custom carbide nozzles, fast delivery. SMT carbide nozzles, sandblasting nozzles, boron carbide nozzles, 3D printer nozzles.

- Info

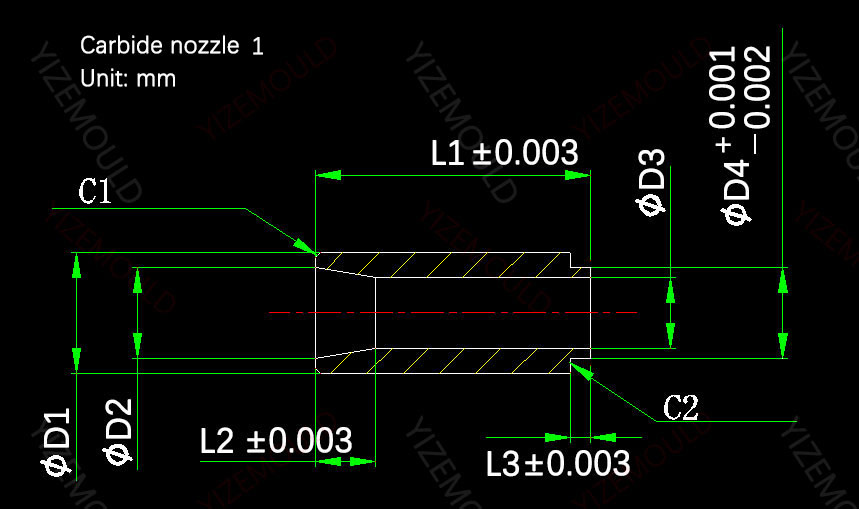

The first Case study for a tungsten carbide nozzle

- The production process of small tungsten carbide nozzles involves the use of a carbide punch grinder and an internal grinding machine. In contrast, the production process for larger tungsten carbide nozzles includes both internal and external grinding.

Tolerance control:

- The tungsten carbide nozzle’s concentricity processing can achieve a tolerance of ±0.001mm

- The vertical parallelism can reach ±0.002mm

- The mirror polishing can reach RA0.01

- The minimum hole processing can reach 0.06mm with a thickness of 0.6mm.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

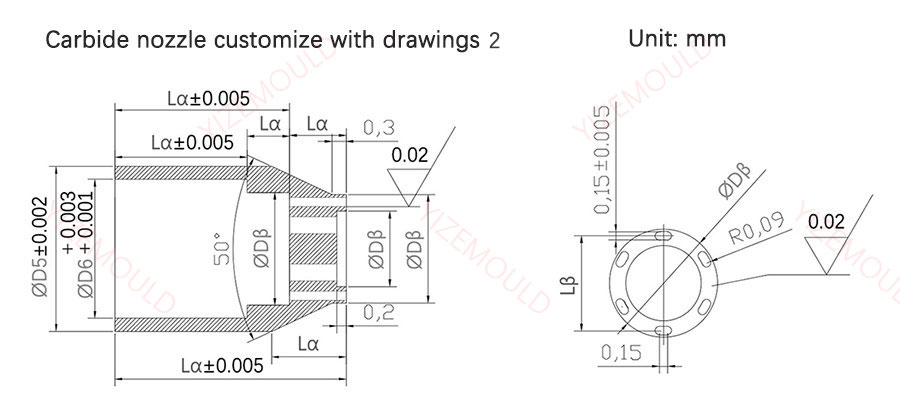

The second Case study for tungsten carbide nozzle

The tungsten carbide nozzle is manufactured using CNC, WEDM, EDM, internal and external grinding, and Carbide surface grinder processes. To ensure the overall quality and performance of the product, it is important to address the following issues:

- Control the D5 location on the external part of the tungsten component to meet the design specifications.

- Ensure the concentricity tolerance of the tungsten carbide inner hole for the D6 location to ensure proper fluid flow.

- Achieve a mirror finish with a tolerance of Ra0.02 for the smaller oval hole in the nozzle head, which can be challenging.

- The QC department is responsible for controlling the quality of every tungsten carbide part, ensuring that each product meets the required specifications.

Additionally, the product needs to be blackened or coated, which requires careful consideration during the manufacturing process. Machining tolerance must be pre-allocated in advance according to the design specifications to avoid any deviations.

The carbide hole slow wire walking process can achieve a tolerance of 0.1mm for special-shaped holes and can polish a 0.1mm diameter hole with a tolerance of Ra0.01. The product drawings are specifically evaluated for higher requirements to ensure that the final product meets the required specifications.

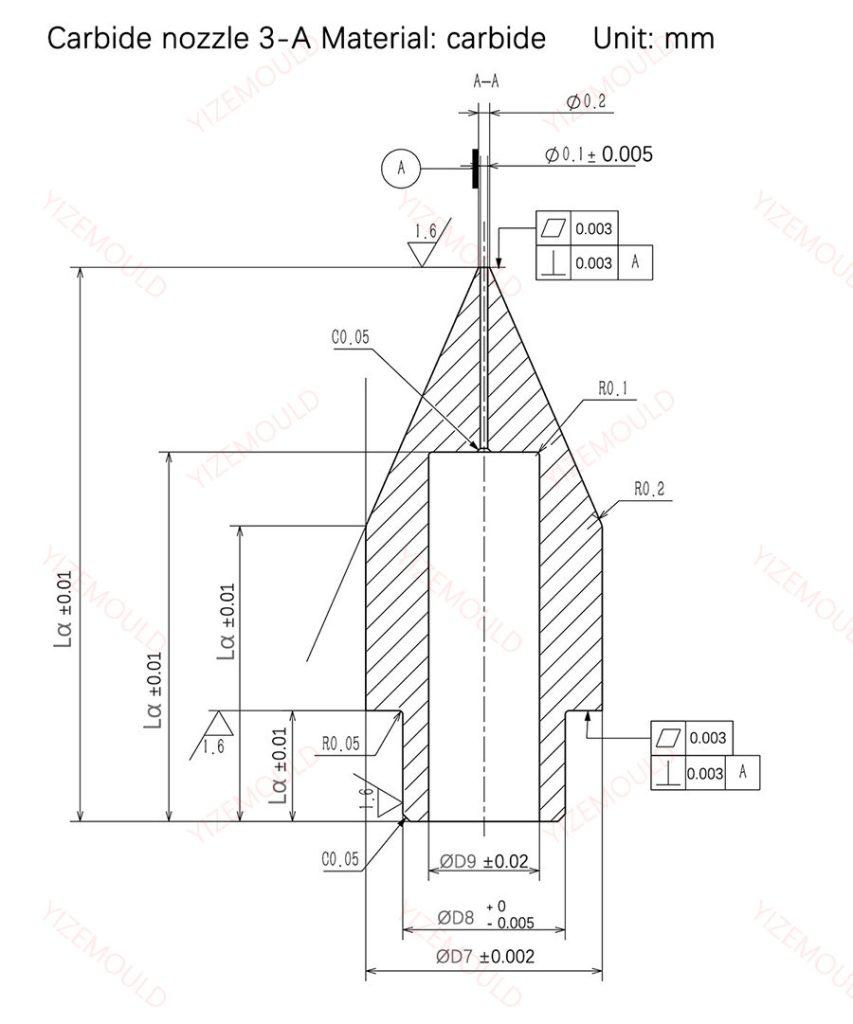

The third Case study for tungsten carbide nozzle

This product is made using a combination of a Carbide punch grinder, Micro EDM, EDM, and WEDM processes. It consists of two parts – a carbide material nozzle part and an HSS material part. Once the two components are processed, the Cold Piercing Process is used to press the tungsten carbide nozzle part onto the main part of the HSS material with impact force.

One of the key challenges we face:

It is achieving the required specifications for the 0.1mm fine hole on the head of the tungsten carbide nozzle (A part). Fortunately, the slow wire walking process used for carbide hole machining can achieve a 0.1mm special-shaped hole, with an effective depth of 0.5mm.

Additionally, the vertical parallelism can reach ±0.002mm, ensuring that the hole meets the necessary standards.

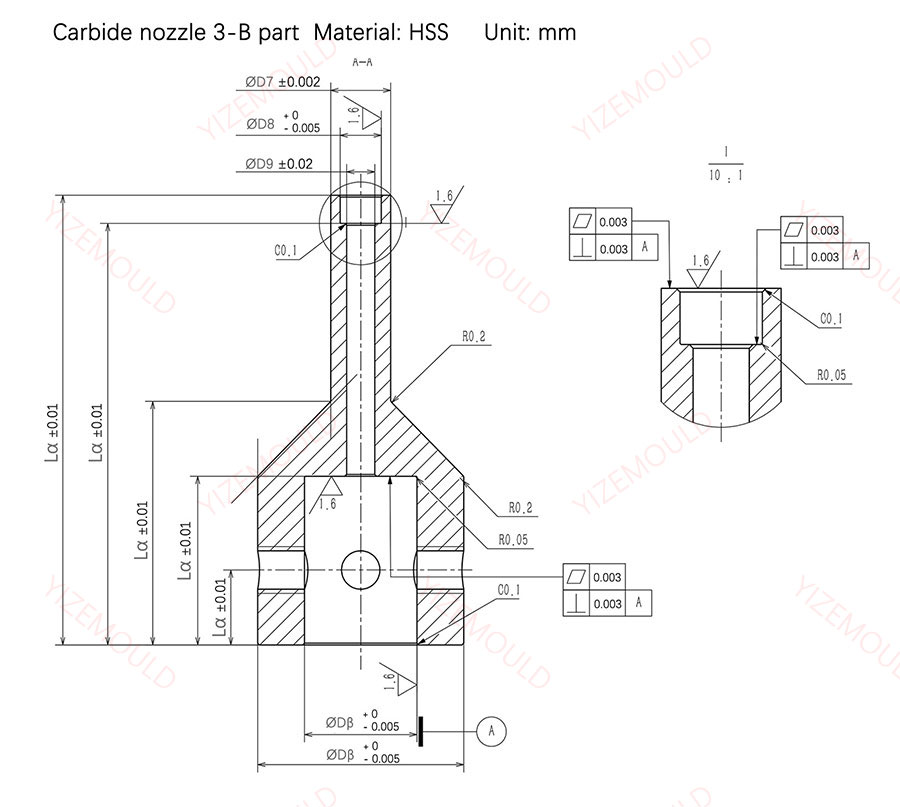

The product consists of a carbide nozzle and HSS material for the below parts.

The manufacturing process includes punch making, EDM, WEDM, and hydraulic press. A suitable material is chosen for the B parts to avoid cracking during Cold Piercing Process.

The problem as blew:

- The product’s structure is complex, and tight tolerance requirements must be met.

- Precise manufacturing techniques are used, which include a variety of different processes.

- Machining tolerances must be pre-allocated to ensure the product meets the required specifications.

- The hardness of the HSS material must be carefully controlled to avoid issues during manufacturing.

Established in 2007, Dongguan Yize Mould is a professional carbide parts factory with a team of 140+ experienced workers specializing in tungsten carbide parts. We are equipped with high-precision equipment to support the manufacturing process, ensuring that our products meet the highest standards of quality.

We specialize in customizing mold parts such as carbide nozzle, carbide sandblasting nozzle, phaetus tungsten carbide nozzle, carbide blast nozzle, and tungsten 3d printer nozzle. according to our customer’s drawings and specifications. Our experienced team utilizes advanced equipment and techniques to ensure precision and accuracy in every product we manufacture.

Related articles: