-

-

What are silicon carbide grinding wheels used for?

I. Introduction to silicon carbide grinding wheels Silicon carbide grinding wheels, made of silicon carbide abrasives and binders, are widely used in the grinding industry due to their high hardness, […]

More

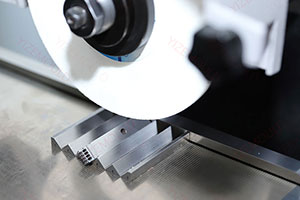

carbide grinders

Various advanced grinding machines, providing carbide machining service in China, tolerance 0.001mm. OD, ID, centerless, profile grinding, and surface grinding on carbide.

-

-

What is carbide grinding?

Carbide grinding typically refers to the processing of carbide using grinding machines. It can also indicate the carbide tools used on the grinding machines, such as carbide grinding heads, carbide […]

More

-

-

How to grind tungsten carbide holes?

Tungsten carbide, with its hardness reaching 85° to 90° HRA and excellent wear resistance, has become a commonly used material in the field of mold processing. However, grinding tungsten carbide […]

More

-

-

How to grinding carbide with surface grinder?

A surface grinder is a precision machining tool widely used in industrial production, especially suitable for grinding materials with high hardness, such as tungsten carbide. This article introduces how to […]

More

-

-

Grinding wheels for carbide

Cheap processing factory. Carbide are widely used in industry. In addition to processing equipment and skilled personnel, grinding wheels are also a major factor. In recent years, the lack of breakthroughs in grinding wheel

More

-

-

EDM carbide

Provide tungsten carbide electrical discharge machining services and customize precision carbide parts for EDM. China company, low-priced and high-quality.

More

-

-

Carbide sleeve

Low-priced China manufacturer buy custom tungsten carbide sleeves, bushings, bearings. Professional precision tungsten carbide components processing supplier.

More

-

-

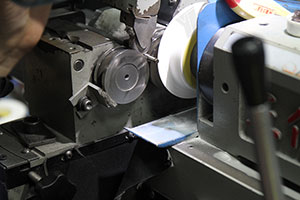

Carbide grinding machining

Low-priced China manufacturer. Custom tungsten carbide precision grinding supplier. Advanced OD, ID, centerless, profile grinding, surface grinding on carbide.

More