How to grinding carbide with surface grinder?

A surface grinder is a precision machining tool widely used in industrial production, especially suitable for grinding materials with high hardness, such as tungsten carbide. This article introduces how to […]

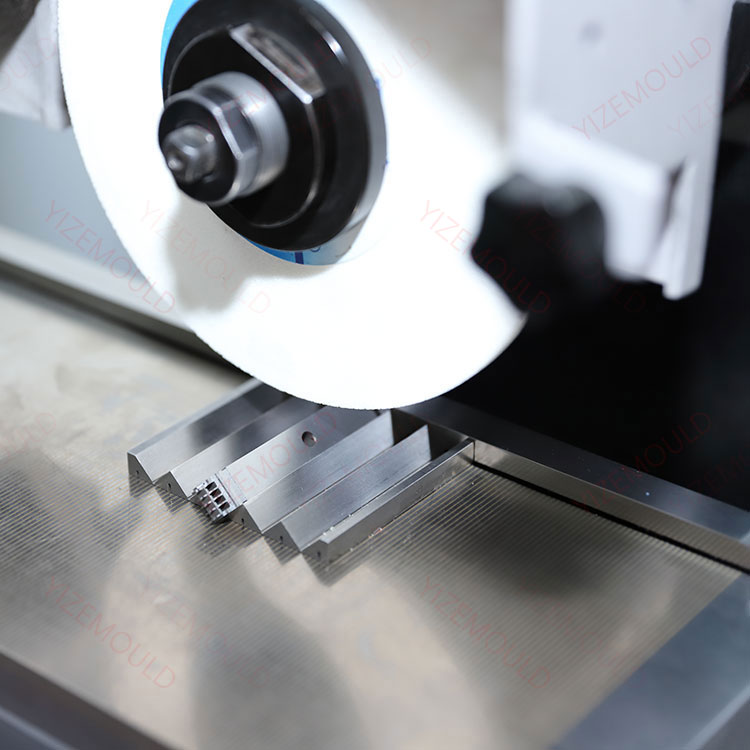

A surface grinder is a precision machining tool widely used in industrial production, especially suitable for grinding materials with high hardness, such as tungsten carbide. This article introduces how to use a surface grinder to grind tungsten carbide, different methods for grinding tungsten carbide, and common grinding techniques.

I. Tungsten carbide grinding methods.

- Using formed grinding wheels Grind the wheel to match the inverse shape of the workpiece’s profile and then use it to grind the tungsten carbide, sharpening it to achieve the desired product shape.

- Part clamping methods Tungsten carbide parts can be clamped on special fixtures under certain conditions, fixed, or constantly repositioned for grinding to achieve the required shape.

- Grinding thin tungsten carbide parts Use an elastic clamping mechanism to position and hold thin workpieces in a free state. Additionally, use a flat-nose pliers in the surface grinder’s accessories to hold the small flat-nose pliers and magnetically attach the tungsten carbide part to the magnetic chuck.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding. email: [email protected],whatsapp:+8618638951317.

II. Surface grinder grinding techniques.

- Conical surface grinding Rotate the upper worktable to an appropriate angle according to the size of the part’s semi-cone angle for grinding, and use gauges or plug gauges to correct the angle.

- Spindle box method grinding Large conical surfaces and short conical surfaces are usually mounted on chucks and ground by turning the spindle box.

- Rotating grinding wheel method Suitable for surface grinders, particularly for grinding surfaces that are low in the middle.

III. Common grinding processes.

- Grinding overlong tungsten carbide parts Alternately grind both ends of the tungsten carbide part, avoiding grinding on the side of the grinding stone, and finally use a fine grinding stone to clean up the edges.

- Grinding small workpieces For precision tungsten carbide parts, clean the edges, especially for hard materials, using finer grinding stones.

- Double-sided grinding Pay attention to leaving a specific process platform on each side to provide support points for polishing and trimming steps.

- Various grinding methods for surface grinders Includes horizontal axis torque table surface grinders, vertical axis rotary table surface grinders, etc., each with its specific application scenarios.

If you have experience in grinding tungsten carbide with a surface grinder, feel free to leave a comment sharing your tips or any suggestions.