Comprehensive Analysis of Common Issues and Root Causes in Tungsten Carbide Compaction Processes

Tungsten carbide, renowned for its exceptional hardness, wear resistance, and thermal stability, serves as a cornerstone material in cutting tools, precision molds, and high-wear components. However, the compaction process—a critical […]

Tungsten carbide, renowned for its exceptional hardness, wear resistance, and thermal stability, serves as a cornerstone material in cutting tools, precision molds, and high-wear components. However, the compaction process—a critical stage in powder metallurgy—often encounters challenges due to material properties, process parameters, and equipment conditions. This article systematically dissects typical defects in tungsten carbide compaction, offering actionable solutions to enhance product quality and process efficiency.

1. Insufficient Compaction Force: The Root Cause of Density Defects

Inadequate compaction force leads to uneven density distribution, voids, or even cracks, severely compromising product performance. Key contributing factors include:

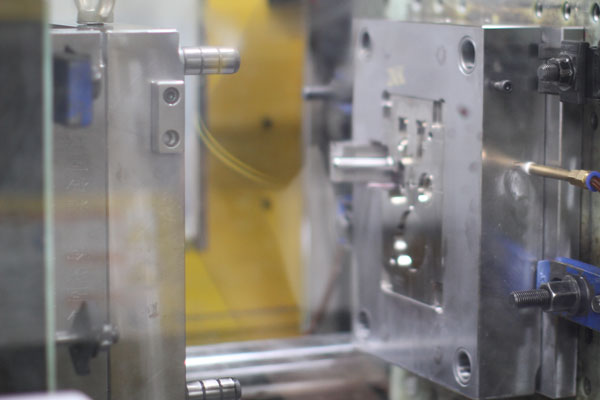

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Mold Design Flaws

- Cavity Geometry Errors: Dimensional deviations exceeding ±0.02mm in cavity depth or diameter increase powder filling resistance by 30%+.

- Guidance System Malfunctions: Clearances >0.05mm between guide columns and bushings cause misalignment, reducing effective compaction force to 60–70% of settings.

- Machine Parameter Mismatches

- Pressure Curve Deviations: Pressure peaks 15% below settings decrease relative density by 5–8%.

- Speed-Pressure Discoordination: Compaction speeds >50mm/s shorten particle rearrangement time, creating localized density voids.

- Raw Material Anomalies

- Particle Size Irregularities: D90/D10 ratios >5 induce stress concentration points, while fine particles impair filling uniformity.

- Excessive Moisture Content: Raw materials with >0.5% moisture generate 0.2–0.5MPa internal pressure during compaction, disrupting force fields.

Solutions:

- Optimize mold cavity geometry via finite element analysis (FEA).

- Implement real-time pressure-displacement monitoring systems.

- Apply three-stage powder sieving (200/325/400 mesh) and vacuum drying (≤0.1% moisture).

2. Product Cracking: Consequences of Uncontrolled Stress

Cracking stems from internal stress imbalances during compaction, with critical triggers including:

- Dynamic Compaction Failures

- Velocity Shock Effects: Speeds >30mm/s raise local temperatures by 50–80°C via friction, triggering thermal stress cracks.

- Insufficient Dwell Time: Dwell times <15s result in 0.8–1.2% elastic rebound, propagating microcracks.

- Oxidation-Induced Brittleness

- Oxygen Content Thresholds: >0.3wt% oxygen forms brittle Co₃O₄ phases, reducing flexural strength by 20–30%.

- Degassing Process Omissions: Undegassed materials release 0.5–1.2cm³/g gas during compaction, forming microscopic pore networks.

- Thermal Field Distortions

- Overheating Brittleness: Temperatures >160°C soften cobalt binders, weakening particle bonding.

- Low-Temperature Hardening: Temperatures <120°C reduce powder flowability (Hall Flow Rate) by 40%, causing delamination cracks.

Technical Countermeasures:

- Adopt segmented compaction (dual-parameter pressure-speed control).

- Implement hydrogen reduction pretreatment (oxygen ≤ 0.1 wt%).

- Develop coupled temperature-pressure control models with ±5°C stability.

3. Density Gradients: Hidden Risks to Performance Consistency

Uneven density leads to >3HRA hardness fluctuations and 20–30% wear resistance variations. Primary causes include:

- Powder Flow Disruptions

- Size Distribution Imbalances: Coarse particles (>10μm) >30% induce “arching effects,” reducing local density by 15–20%.

- Morphological Anisotropy: High proportions (>20%) of acicular WC particles create directional flow, generating density gradients.

- Mold Degradation

- Cavity Wear: Mold hardness (HRC) <55 results in 0.03–0.05mm/10,000 cycles dimensional expansion.

- Inadequate Elastic Compensation: Absence of 0.5–1.0mm compensation gaps causes 1.2–1.8% post-demolding density rebound.

Optimization Pathways:

- Establish powder flowability testing (repose angle ≤35°, compressibility index ≥2.8).

- Repair worn mold surfaces via laser cladding.

- Develop adaptive dwell pressure control systems (pressure stability ≤±1%).

4. Mold Damage: The Achilles’ Heel of Process Chains

Mold failures disrupt production and escalate costs (repair expenses reach 30–50% of mold value). Typical failure modes include:

- Material Selection Errors

- Hardness Deficits: Mold steels <HRC58 exhibit 0.1–0.2mm wear after 1,000 cycles.

- Toughness Gaps: Materials with <30J/cm² impact toughness are prone to microcrack propagation.

- Structural Stress Concentrations

- Insufficient Fillet Radii: Cavity corners <0.5mm induce stress concentration factors of 3–5x.

- Cooling Channel Design Flaws: Flow rates <0.5m/s cause localized overheating and thermal fatigue cracks.

- Operational Overloads

- Overpressure Shocks: Pressures >80% of mold yield strength reduce fatigue life to 1/3 of normal.

- Thermal Shocks: Temperature fluctuations >80°C/min cut thermal stress cycles by 60%.

Protective Strategies:

- Select hot work tool steels (e.g., H13) with ion nitriding (hardness ≥HRC60).

- Optimize mold fillet radii (R≥2mm) via FEA.

- Implement dual-parameter pressure-temperature monitoring with automatic shutdown protection.

Conclusion: Toward Closed-Loop Process Quality

Defect prevention in tungsten carbide compaction requires holistic integration of material, mold, equipment, and process controls. Deploying online density monitoring, intelligent mold diagnostics, and adaptive parameter algorithms can reduce defect rates from 8% to <2%. The future lies in digital twin technologies, enabling predictive-controlled-optimized smart compaction systems.