Interpretation of Processing Specifications for Tungsten Carbide Drawing Dies

In the grand landscape of industrial production, tungsten carbide drawing dies shine like a brilliant gem. With their high hardness, high strength, and excellent wear resistance, they play an irreplaceable […]

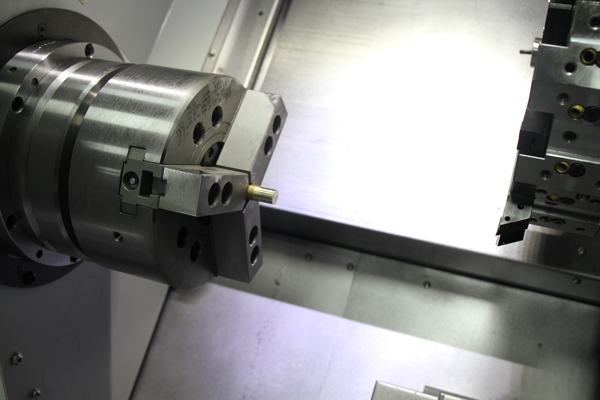

In the grand landscape of industrial production, tungsten carbide drawing dies shine like a brilliant gem. With their high hardness, high strength, and excellent wear resistance, they play an irreplaceable and crucial role in numerous fields. Whether it’s the manufacturing of precision electronic components or the forming of large – scale mechanical parts, tungsten carbide drawing dies provide precise assistance without which the production process would be severely hindered. The processing specifications of these dies are like the cornerstone of building an industrial fortress, directly determining the accuracy and production efficiency of the dies, and further influencing the smoothness of the entire production process and the quality of the final products. Next, let’s delve into the mysteries of the processing specifications of tungsten carbide drawing dies.

1. Die Plate Size and Position of Locking Screws: The Golden Rule for a Solid Foundation

In the processing of tungsten carbide drawing dies, the size of the die plate is a core specification. To endow the die with strong stability and high – efficiency working capabilities, the size of the die plate must be carefully planned and must be larger than the working area. This ingenious design is not arbitrary but is based on a profound consideration of the enormous pressure and intense impact that the die will bear during actual work. Choosing standard die plate sizes for processing is like building a sturdy armor for the die, enabling it to remain as stable as a mountain in the complex and ever – changing industrial environment.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

At the same time, the configuration of the positions of the locking screws on the die plate is also of great importance and cannot be overlooked. The positions of the screws are like the “joints” of the die, which are not only related to the stability of the die but also directly affect its service life and working efficiency. In single – stage dies, configuring the locking screws at the four corners is a clever move, similar to building four solid supports for the die, ensuring that it remains stable and in the correct position during the working process. For long dies and continuous dies, in addition to the four corners, configuring locking screws at the intermediate positions further enhances the overall stability of the die, enabling it to handle various complex drawing tasks with ease.

2. Die Plate Thickness: The Art of Balancing Load – Bearing Capacity and Efficiency

The thickness of the die plate, as one of the key processing specifications of tungsten carbide drawing dies, is like a double – edged sword, playing a delicate balancing role between the load – bearing capacity, wear resistance, and service life of the die. The selection of the die plate thickness is not a simple matter but is closely related to many factors such as the structure of the die, the type of drawing processing, the drawing force, and the drawing accuracy.

A die plate that is too thin is like a fragile dancer. Under long – term working pressure, it is very prone to deformation or even damage, causing the die to malfunction and affecting the production schedule. On the other hand, a die plate that is too thick, although seemingly extremely sturdy, is like a slow – moving giant. It not only increases production costs but also reduces the flexibility and working efficiency of the die. Therefore, when selecting the die plate thickness, it is necessary to comprehensively consider various factors, just like an experienced artist seeking a perfect balance between art and practicality. Generally speaking, theoretical calculations can hardly accurately determine the thickness of the die, and more often, it relies on rich experience and practical application situations. To ensure the performance and cost – effectiveness of the die, the types of die plate thickness used in design should be as unified as possible. At the same time, standardization should be carried out in combination with the die height and clamping height, which not only facilitates procurement and inventory management but also improves production efficiency.

3. Material Selection and Heat Treatment: The Magic for Forging Excellent Die Performance

The selection of materials for tungsten carbide drawing dies is a crucial link in the processing specifications. High – quality tungsten carbide materials are like injecting powerful vitality into the die, which can ensure that the die has excellent hardness and wear resistance, thereby greatly improving its service life. When selecting materials, it is necessary to be as meticulous as a rigorous scientist, carefully considering factors such as the composition, purity, and heat treatment process of the materials. Different material compositions and purities will have a significant impact on the performance of the die, and the heat treatment process is the key to unlocking the excellent performance of the die.

Heat treatment, as a key step to ensure the performance of the die, is like a magical spell. Through heat treatment processes such as annealing and quenching, the hardness and wear resistance of the die can be further enhanced, enabling it to maintain outstanding performance even in harsh working environments. These processes need to be precisely controlled according to the specific uses and working conditions of the die, just like a skilled magician accurately casting spells to ensure that the die can maintain stability and high efficiency during use.

4. Surface Treatment and Accuracy Requirements: The Finishing Touches for Enhancing Die Quality

In addition to the above – mentioned key specifications, the surface treatment of tungsten carbide drawing dies is also an important aspect that cannot be ignored. Through advanced surface treatment techniques such as polishing, it is like putting a smooth coat on the die, which can further improve the surface finish and processing accuracy of the die. This not only helps to reduce the friction and wear between the die and the material, reducing energy consumption but also significantly improves the working efficiency and product quality of the die, making the products produced more exquisite and of higher quality.

At the same time, accuracy requirements are also a key factor in the processing specifications of the die, which can be regarded as the finishing touches for enhancing die quality. A high – precision die, like a highly skilled craftsman, can ensure that the dimensional accuracy and shape accuracy of the products reach the highest level, thereby improving production efficiency and product quality. During the processing, it is necessary to strictly control various process parameters, just like a meticulous quality inspector, to ensure that the accuracy of the die meets the design requirements and lay a solid foundation for producing high – quality products.

5. Conclusion

In conclusion, the processing specifications of tungsten carbide drawing dies are like a colorful and magnificent picture scroll here, but in a more technical context, it can be understood as a complex and comprehensive set of rules), covering multiple aspects such as die plate size and position of locking screws, die plate thickness, material selection and heat treatment, as well as surface treatment and accuracy requirements. These specifications are interrelated and influence each other, jointly forming a solid guarantee for the performance and service life of the die, and directly affecting production efficiency and product quality. Therefore, during the processing, we must strictly abide by these specification requirements, with a rigorous attitude and superb skills, to ensure the accuracy and stability of the die. At the same time, with the continuous progress of science and technology and the rapid development of industry, we have reason to believe that in the future, more innovative technologies and materials will be applied to the manufacturing of tungsten carbide drawing dies, injecting new vitality into the improvement of their performance and service life and pushing industrial production to a more glorious future.