A Comprehensive Analysis of Precision Detection Methods for Tungsten Carbide Dies

In the vast landscape of industrial production, tungsten carbide dies, with their outstanding characteristics of high hardness, high wear resistance, and high heat resistance, occupy a pivotal position. The precision […]

In the vast landscape of industrial production, tungsten carbide dies, with their outstanding characteristics of high hardness, high wear resistance, and high heat resistance, occupy a pivotal position. The precision of dies is akin to the precise rhythm in the symphony of industrial production, directly determining the quality of products and the efficiency of production. Therefore, conducting scientific and accurate precision detection on tungsten carbide dies is a key link in ensuring the smooth progress of industrial production. This article will provide an in-depth and comprehensive introduction to several major precision detection methods for tungsten carbide dies.

Visual Inspection: Intuitively Identifying Surface Defects

Visual inspection, as the most basic and intuitive detection method, is like a keen observer. It uses the naked eye or a magnifying glass to carefully examine the surface of tungsten carbide dies. It can quickly capture surface defects such as cracks, bubbles, and inclusions, and the operation is simple and easy to carry out without complex equipment or cumbersome procedures. However, it also has obvious limitations. Like an observer with limited vision, it can only focus on the surface of the die and is powerless against defects hidden inside the die. Moreover, the accuracy of its detection results largely depends on the experience and skills of the inspector. Different inspectors may reach different conclusions due to subjective differences in judgment.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

When conducting visual inspection, creating a well-lit environment is crucial. Sufficient light, like a bright searchlight, enables inspectors to clearly observe the minute details on the die surface. At the same time, inspectors need to have received professional training, like well-trained soldiers, to accurately identify various surface defects and make objective and reasonable assessments of the overall quality of the die.

Magnetic Particle Inspection: Magnetic Fields Unveiling Ferromagnetic Defects

Magnetic particle inspection is like a mysterious magician who uses the magical power of magnetic fields to reveal the secrets of surface and near-surface defects in dies. It is specially designed for dies made of ferromagnetic materials. During the inspection process, a layer of magnetic powder is first evenly coated on the surface of the die, as if putting a mysterious veil on the die. Then a magnetic field is applied to make the magnetic field lines traverse through the die. When the magnetic field lines encounter defects, the magnetic powder will form unique magnetic traces at the defect sites, like indicators lighting up in the dark, clearly revealing the location and shape of the defects.

The advantages of magnetic particle inspection are significant. It can accurately detect surface and near-surface defects in dies, and the operation is relatively simple with low cost. However, it also has its own “Achilles’ heel.” It is only applicable to dies made of ferromagnetic materials and is powerless against non-ferromagnetic materials.

When conducting magnetic particle inspection, selecting appropriate magnetic powder and magnetic field strength is the key. They are like the magical props in the hands of a magician, directly affecting the accuracy and reliability of the inspection. At the same time, inspectors need to be familiar with the principles and operation skills of magnetic particle inspection, like mastering magic spells, to avoid misjudgments or missed detections and ensure accurate inspection results.

Ultrasonic Inspection: Sound Waves Exploring Internal Hidden Problems

Ultrasonic inspection is like an explorer well-versed in the secrets of sound waves. It uses the unique characteristics of ultrasonic waves propagating in materials to delve deep into the interior of dies and search for hidden defects. When ultrasonic waves propagate in a die, they will encounter defects as if they encounter obstacles, producing reflection and scattering phenomena. By analyzing these phenomena, like decoding a mysterious code, it is possible to determine whether there are defects inside the die and the location and size of the defects.

The advantages of ultrasonic inspection are prominent. It can penetrate deep into the die and detect hidden defects with high precision. However, it is also like a noble gentleman that requires professional equipment and operation techniques to “serve,” with relatively high costs. Moreover, the propagation of ultrasonic waves in materials is affected by various factors such as material density and elastic modulus, like an explorer navigating through complex terrain, and these factors need to be comprehensively considered to accurately interpret ultrasonic signals.

When conducting ultrasonic inspection, selecting appropriate probes and frequencies is the key to success. They are like the essential tools for an explorer, ensuring that ultrasonic waves can effectively propagate in the die and accurately capture defect signals. In addition, inspectors need to have professional knowledge and skills, like experienced explorers, to accurately analyze and interpret ultrasonic signals and obtain accurate and reliable inspection results.

Other Inspection Methods: Diverse Approaches Showcasing Unique Strengths

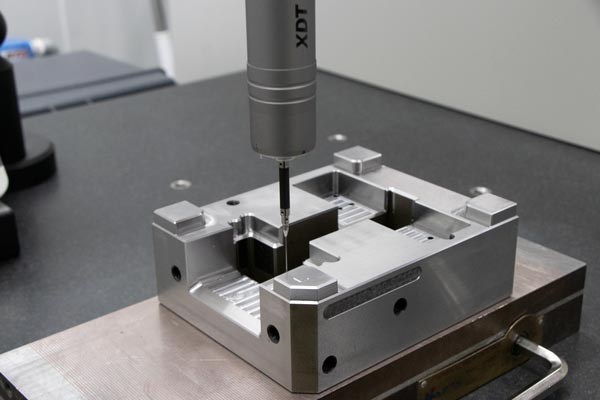

In addition to the above three commonly used inspection methods, there are many other inspection methods that shine like bright stars in the sky of precision detection for tungsten carbide dies. For example, a coordinate measuring machine (CMM) is like a precise sculptor that can accurately measure the dimensions and shapes of dies, providing detailed data support for precision control of dies. X-ray or gamma-ray inspection is like a doctor with X-ray vision that can penetrate the surface of the die and reveal its internal defects and structural abnormalities, leaving no hidden problems unexposed. Infrared thermal imaging technology is like a sensitive temperature感知者 (the English equivalent could be “temperature sensor”) that can detect temperature changes in dies during use and indirectly reflect the quality and performance status of the die through abnormal temperature changes.

These methods each have their own advantages and disadvantages and are suitable for different inspection needs and scenarios. In practical applications, we should act like wise commanders, select appropriate inspection methods or combine multiple methods according to specific situations to form a powerful inspection force and improve the accuracy and reliability of inspection.

Summary and Outlook: Innovation Leading the Future of Inspection

The precision detection of tungsten carbide dies is the core link in ensuring die quality and product performance. This article has detailed several major inspection methods and their advantages and disadvantages, including visual inspection, magnetic particle inspection, and ultrasonic inspection. They are like multiple sharp blades in the field of inspection, each with its unique advantages and applicable scope. With the continuous progress of science and technology and the vigorous development of industrial production, the requirements for die precision are becoming increasingly stringent, like the challenges of climbing higher peaks constantly escalating. Therefore, in the future, it is necessary to continuously explore and innovate more advanced inspection methods and technologies, like developing more powerful weapons and equipment, to meet the needs of industrial production.

At the same time, we should also be clearly aware that any inspection method has certain limitations and error ranges, like there is no absolutely perfect tool. In practical applications, we need to comprehensively consider various factors such as cost, efficiency, and accuracy, like weighing the pros and cons in a complex chess game, and select appropriate inspection methods or combine multiple methods to improve the accuracy and reliability of inspection. In addition, strengthening the professional training of inspectors is also a key factor in improving inspection quality, like providing elite training for soldiers so that they can master various inspection skills proficiently.

Finally, with the rapid development of intelligent manufacturing and automation technology, it is expected to achieve more intelligent and automated die precision inspection systems in the future, like equipping industrial production with an intelligent butler. This will further improve inspection efficiency and quality, bring greater convenience and benefits to industrial production, and push industrial production towards a more glorious future.