Advantages of Tungsten Carbide Die in High-Precision Machining

Introduction In the process of modern industrial development, the field of high-precision machining is like the core engine of precision manufacturing, driving numerous industries towards higher quality and more refined […]

Introduction

In the process of modern industrial development, the field of high-precision machining is like the core engine of precision manufacturing, driving numerous industries towards higher quality and more refined directions. In this crucial field, dies, as the “mother machines” of machining, play a decisive role in controlling machining accuracy, efficiency, and product quality. Tungsten carbide die, with its unique physical and chemical properties, shines like a brilliant star on the stage of high-precision machining, demonstrating unparalleled significant advantages. This article will delve into the unique advantages of tungsten carbide die in high-precision machining and combine practical application cases to help readers gain a more comprehensive and in-depth understanding of its outstanding performance in high-precision machining.

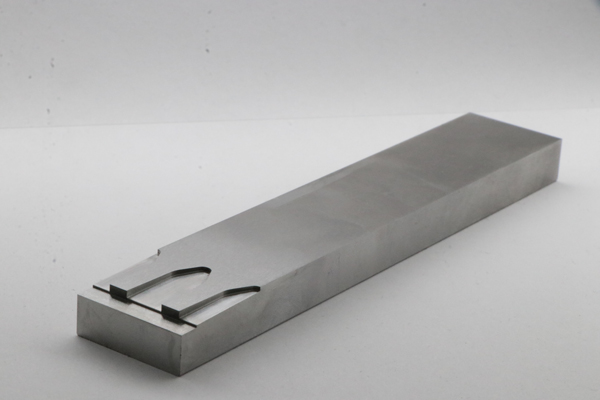

Basic Characteristics of Tungsten Carbide Die

Tungsten carbide, also known as cemented carbide, is a composite material carefully prepared from tungsten carbide (WC) and metal binders (such as cobalt, nickel, etc.). It combines numerous excellent characteristics, including high hardness, high wear resistance, high corrosion resistance, and high thermal stability, which make it occupy a pivotal position in the field of high-precision machining dies.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- High Hardness: The hardness of tungsten carbide far exceeds that of traditional steel. The hardness of commonly used tungsten carbide can reach above HRC60 – 70. Such high hardness enables the tungsten carbide die to remain as stable as a rock in terms of dimensional accuracy and shape accuracy when facing harsh working environments with high pressure and high temperature, laying a solid foundation for high-precision machining.

- High Wear Resistance: The tungsten carbide particles in tungsten carbide are like tiny “diamond drill bits,” possessing extremely high hardness and wear resistance. During the machining process, they can effectively resist the invasion of wear and scratches, greatly extending the service life of the die and thus reducing production costs and saving valuable resources for enterprises.

- High Corrosion Resistance: Tungsten carbide die has excellent chemical stability, as if wearing a solid “protective armor,” which can strongly resist the erosion of chemical corrosives such as acids and alkalis. Even in harsh environments, it can maintain stable performance and ensure the smooth progress of the machining process.

- High Thermal Stability: Tungsten carbide has a very low coefficient of thermal expansion, acting like a “calm guardian” that can maintain stable dimensional accuracy even under high-temperature conditions. This characteristic makes the tungsten carbide die stand out in high-temperature machining and demonstrate unique advantages.

Advantages of Tungsten Carbide Die in High-Precision Machining

Ensuring Machining Accuracy

In the precise world of high-precision machining, the accuracy of the die is the “lifeline” of the product, directly determining the accuracy and quality of the product. With its high hardness and high wear resistance, the tungsten carbide die can act like a precise “craftsman” throughout long-term use, always maintaining stable dimensional accuracy and shape accuracy. Moreover, its good thermal stability is the icing on the cake, ensuring dimensional accuracy even at high temperatures and providing double protection for machining accuracy.

For example, in the field of precision die manufacturing, tungsten carbide die is the first choice for producing high-precision and high-quality plastic dies and die-casting dies. These dies need to work under harsh conditions of high temperature and high pressure, and the tungsten carbide die, with its excellent physical properties, acts like a reliable “guardian,” ensuring the accuracy and stability of the die and thus producing high-quality products.

Improving Machining Efficiency

The wear resistance of tungsten carbide die is remarkable, making it like a “resilient warrior” during the machining process, not prone to wear and greatly reducing the frequency of die replacement and downtime. At the same time, its high hardness endows it with the ability to withstand higher cutting speeds and feed rates, acting like an “accelerator” for machining and significantly improving machining efficiency.

In the aviation and aerospace fields, which have extremely high precision requirements, tungsten carbide die plays a crucial role. It is widely used in the production of high-precision parts. The machining difficulty of these parts is extremely high, requiring high-precision dies to ensure machining accuracy. The tungsten carbide die successfully meets these strict requirements with its high precision and wear resistance, improving machining efficiency and reducing production costs, providing strong support for the development of the aviation and aerospace industries.

Reducing Production Costs

The long service life of the tungsten carbide die is like having a “long-lived partner,” which can reduce the frequency of die replacement and downtime, thereby reducing production costs. In addition, its good chemical stability enables it to resist the erosion of chemical corrosives, reducing the maintenance and repair costs of the die and saving a large amount of funds for enterprises.

Taking the automotive manufacturing field as an example, tungsten carbide die plays an important role in the production of high-precision parts such as engine cylinder blocks and crankshafts. The machining requirements for these parts are extremely high, requiring high-precision dies to ensure machining accuracy. The tungsten carbide die successfully meets these requirements with its high precision and long service life, reducing production costs and improving the economic benefits of enterprises, helping the automotive manufacturing industry stand out in the fierce market competition.

Environmental Protection and Energy Conservation

The good chemical stability of the tungsten carbide die enables it to effectively resist the erosion of chemical corrosives, reducing environmental pollution and acting like an “environmental protector” to contribute to environmental protection. At the same time, its high thermal stability allows it to maintain stable dimensional accuracy at high temperatures, reducing energy waste and achieving the goal of energy conservation.

In today’s world, where environmental protection and energy conservation are increasingly becoming global concerns, the application of tungsten carbide die is of great significance. With the continuous improvement of environmental awareness and the increasing scarcity of energy resources, using tungsten carbide die for high-precision machining can not only improve product quality and production efficiency but also reduce energy consumption and environmental pollution, meeting the requirements of sustainable development and contributing to the construction of a beautiful planet.

Conclusion

In conclusion, the advantages of tungsten carbide die in high-precision machining shine like bright stars in ensuring machining accuracy, improving machining efficiency, reducing production costs, and achieving environmental protection and energy conservation. With its excellent characteristics such as high hardness, high wear resistance, high corrosion resistance, and high thermal stability, the tungsten carbide die has become the “darling” in the field of high-precision machining and plays an irreplaceable important role. Looking ahead, with the continuous development of industrial technology and the changing market demands, the application prospects of tungsten carbide die will be even broader and will surely inject a continuous stream of impetus into the development of the high-precision machining field.