Analysis of Strategies for Improving the Processing Efficiency of Tungsten Carbide Dies

I. Introduction In the diverse landscape of the manufacturing industry, tungsten carbide dies hold a pivotal position due to their outstanding high strength, high wear resistance, and high corrosion resistance […]

I. Introduction

In the diverse landscape of the manufacturing industry, tungsten carbide dies hold a pivotal position due to their outstanding high strength, high wear resistance, and high corrosion resistance across numerous manufacturing sectors. However, the processing of tungsten carbide dies is akin to a highly intricate and challenging “surgical procedure.” How to enhance the processing efficiency in this “procedure” has always been a core issue in the manufacturing field. This article will delve into strategies for improving the processing efficiency of tungsten carbide dies from multiple key dimensions, aiming to provide enterprises with highly practical and actionable reference suggestions to help them gain an edge in the fierce market competition.

II. Optimizing Processing Technology: Precise Regulation for Enhanced Efficiency

(A) Rational Selection of Cutting Parameters

Cutting parameters, encompassing cutting speed, feed rate, and cutting depth, act as the “baton” in the processing operation, directly influencing both processing efficiency and quality. Given the unique physical and chemical properties of tungsten carbide materials and the specific requirements of the dies, it is of utmost importance to select cutting parameters precisely and rationally. Excessive cutting speed can cause the cutting tool to wear out rapidly, similar to an overworked “warrior,” not only affecting processing accuracy but also potentially leading to tool damage and processing interruptions. Conversely, an overly low cutting speed is like a “snail’s pace,” significantly slowing down the processing progress and reducing overall efficiency. The selection of feed rate and cutting depth also requires careful consideration and flexible adjustment based on actual working conditions to achieve optimal processing results.

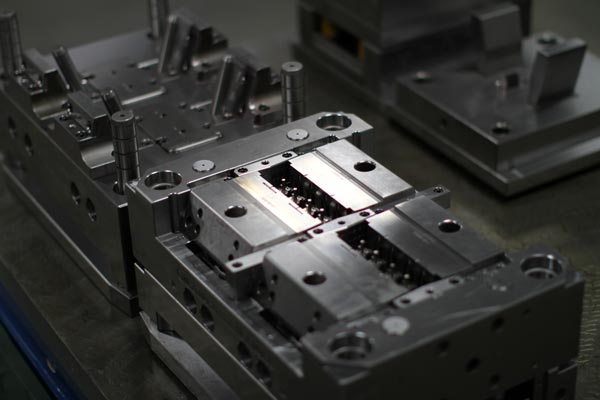

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

(B) Adopting High-Efficiency Processing Technologies

The rapid development of technology has brought about numerous high-efficiency processing technologies for tungsten carbide die processing, such as high-speed cutting technology and hard turning technology. These technologies serve as “accelerators” in the processing field, significantly improving processing efficiency while ensuring processing quality. Take high-speed cutting technology as an example. By substantially increasing the cutting speed and feed rate, it can remove a large amount of material in a short period, akin to “cutting through a Gordian knot,” greatly shortening the processing cycle and enhancing production efficiency.

III. Selecting Appropriate Cutting Tools and Fixtures: Adaptation as the Foundation for Stability

(A) Choosing High-Performance Cutting Tools

Cutting tools, as the “vanguard” of the processing operation, directly determine the level of processing efficiency and quality. When selecting cutting tools, it is essential to focus on key performance indicators such as hardness, wear resistance, and impact resistance. In view of the high hardness and strong toughness of tungsten carbide materials, choosing cutting tools with high strength and high wear resistance can extend the service life of the tools, reduce the time loss caused by frequent tool changes, and thus improve processing efficiency.

(B) Designing Rational Fixtures

Fixtures play the role of a “stabilizer” during the processing operation, and the rationality of their design is directly related to the stability and accuracy of die processing. A well-designed fixture can ensure that the die is firmly fixed during processing, minimizing processing errors caused by vibration or displacement. At the same time, the loading and unloading of the fixture should be convenient and efficient, similar to a “quick-change prop,” reducing auxiliary time and improving production efficiency.

IV. Implementing Refined Management: Standardizing Processes for Cost Reduction and Efficiency Enhancement

(A) Formulating Detailed Processing Plans

Before processing, formulating a detailed processing plan is like drawing a precise “battle map,” covering key aspects such as processing sequence, cutting parameters, and tool selection. This helps ensure that the processing operation proceeds in an orderly manner, avoiding downtime and frequent adjustments caused by inadequate planning, thereby improving production efficiency.

(B) Strengthening Equipment Maintenance and Upkeep

Processing equipment serves as the “cornerstone” of production. Regular maintenance and upkeep of the equipment can ensure that it remains in good operating condition, reducing the probability of failures. Meanwhile, regular inspection and replacement of cutting tools are like equipping “warriors” with high-quality weapons, maintaining the optimal performance of the tools and improving processing efficiency.

V. Introducing Automation and Intelligent Technologies: Empowering with Technology for Innovation and Upgrading

(A) Applying Automation Technologies

Automation technologies are the “secret weapons” for improving the processing efficiency of tungsten carbide dies. For instance, an automatic tool changer system can quickly and accurately change tools, reducing tool-changing time. An automatic measurement and compensation system can monitor processing errors in real-time and make automatic adjustments to ensure processing accuracy. Using robots for material loading and unloading operations can save labor costs and improve production efficiency, enabling 24/7 uninterrupted production.

(B) Utilizing Intelligent Technologies to Optimize the Processing Operation

With the vigorous development of artificial intelligence and big data technologies, intelligent technologies are increasingly being applied in the manufacturing industry. By collecting and analyzing data during the processing operation, cutting parameters can be optimized, tool life can be predicted, and the processing operation can be intelligently controlled. In addition, intelligent technologies can help enterprises achieve visualization and controllability of the production process, enabling managers to grasp production dynamics in real-time, promptly identify problems, and make adjustments, improving the efficiency and accuracy of production management.

VI. Strengthening Employee Training and Management: People as the Core for Unleashing Vitality

(A) Improving Employee Skill Levels

Employees are the core strength of an enterprise’s development. Regular skill training for employees enables them to master the processing technologies and operation methods of tungsten carbide dies proficiently, similar to providing professional training for “warriors.” This can improve employees’ skill levels, reduce operation errors and scrap rates, and thus enhance production efficiency.

(B) Establishing Incentive and Assessment Mechanisms

Establishing reasonable incentive and assessment mechanisms can stimulate employees’ work enthusiasm and creativity. For example, setting up performance bonuses, promotion opportunities, and other incentive measures encourages employees to strive to improve processing efficiency and quality. At the same time, regular assessment and evaluation of employees’ work performance help identify problems in a timely manner and make improvements, creating a positive work atmosphere and a competitive mechanism.

VII. Conclusion and Outlook

Improving the processing efficiency of tungsten carbide dies is a systematic and complex project that requires comprehensive optimization and improvement from multiple aspects such as processing technology, cutting tools and fixtures, management methods, technology application, and employee quality. By implementing the above strategies, enterprises can significantly enhance the processing efficiency and quality of tungsten carbide dies and strengthen their market competitiveness.

Looking ahead, with the continuous progress of technology and the rapid development of industry, the field of tungsten carbide die processing will face more opportunities and challenges. Enterprises should continuously pay attention to the research and application of new technologies and new processes and actively adapt to the ever-changing market demands and customer requirements. At the same time, strengthening exchanges and cooperation with international advanced enterprises, introducing advanced management concepts and technological means, and continuously improving their innovation capabilities and overall strength are crucial. Through continuous innovation and self-improvement, enterprises will contribute important forces to the sustainable development and progress of the tungsten carbide die manufacturing industry and write a more glorious chapter.