Analysis of Tungsten Carbide Die Installation

In the context of the booming modern manufacturing industry, tungsten carbide dies, with their excellent properties such as high hardness and high wear resistance, have become an indispensable key tool […]

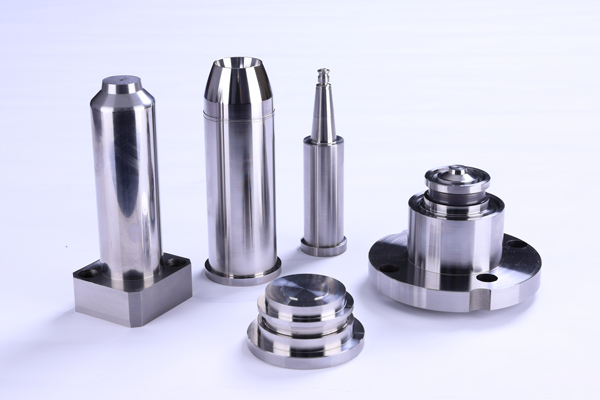

In the context of the booming modern manufacturing industry, tungsten carbide dies, with their excellent properties such as high hardness and high wear resistance, have become an indispensable key tool in numerous production processes. They are like the “precision gears” of the manufacturing sector, and the quality of their installation directly determines the performance and processing efficiency of the dies. Correct installation steps can not only ensure the stable and precise operation of the dies but also significantly extend their service life and improve overall production quality. Next, this article will provide a comprehensive and systematic introduction to the installation steps of tungsten carbide dies.

Before Installation: Careful Preparation, Laying a Solid Foundation

Thoroughly Inspect the Die

Before installation, it is crucial to conduct a comprehensive “physical examination” of the tungsten carbide die. Carefully check whether the die’s dimensions and shape comply with the design standards, inspect the surface for any scratches, pits, or other quality issues, and pay special attention to the presence of potential defects such as cracks and burrs. Only by ensuring that the die is in perfect condition can reliable guarantees be provided for subsequent installation and use.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Fully Prepare the Tools

Based on the structural characteristics and installation requirements of the die, carefully prepare the necessary tools. Lifting equipment is used for the safe handling of the die, wrenches and screwdrivers are for fastening components, and micrometers are for accurately measuring the die’s dimensions. Ensure that all tools are complete and in good working condition to avoid affecting the installation progress and quality due to tool problems.

Completely Clean the Work Area

Before installation, thoroughly clean the work area to remove debris and dust. A clean and interference-free work environment can effectively prevent installation errors and safety accidents caused by the entry of foreign objects or collisions during the installation process, creating favorable conditions for a smooth installation.

During Installation: Precise Operations, Proceeding Step by Step

Die Positioning and Fixing

- Precise Positioning: Place the die steadily on the installation table and determine its exact installation position and orientation according to the die’s structure and installation requirements. Use professional positioning devices such as locating pins and locating blocks to ensure accurate alignment between the die and the installation table, laying a solid foundation for subsequent installation.

- Gently Lift and Slowly Place: Use lifting equipment to slowly and gently lift the die and then gradually lower it onto the installation table. During this process, operators need to be fully focused to avoid collisions or friction between the die and the installation table, preventing damage to the die’s surface.

- Securely Fix: Install fixing devices such as bolts and nuts on the bottom or side of the die and use wrenches and other tools to tighten them. Pay attention to controlling the tightening force to prevent the die from loosening due to insufficient tightening or damage to the die or the installation table due to excessive tightening.

Die Adjustment and Calibration

- Initial Adjustment: After installation, make initial adjustments to the die according to the processing requirements. Use micrometers and other precise measuring tools to accurately adjust parameters such as the opening and closing degree and position of the die to ensure that all indicators meet the processing needs.

- Professional Calibration: Use specialized calibration tools or equipment to comprehensively calibrate the precision of the die. During the calibration process, ensure the accuracy and stability of the calibration tools to obtain reliable calibration results and provide guarantees for the precise operation of the die.

- Re-inspection and Confirmation: After calibration, conduct a detailed re-inspection of the die. Confirm that the die’s precision and stability fully comply with the processing requirements, making full preparations for subsequent processing and production.

Connection between the Die and the Equipment

- Rational Connection: Select appropriate connection methods such as bolt connection or pin connection according to the equipment requirements and the die’s structure to firmly connect the die with the production equipment. Ensure that the connection parts are tight and reliable to prevent loosening or detachment during the processing.

- Inspect Connection Components: During the connection process, carefully check the integrity and reliability of the connection components. If any damage or defects are found in the components, replace or repair them in a timely manner to ensure the safety and stability of the connection.

- Overall Inspection: After connection, conduct an overall inspection of the die and the equipment. Check whether the connection parts are tight and free of gaps to avoid problems such as vibration and noise during processing caused by poor connection.

Trial Run and Adjustment

- Trial Run Inspection: Before formal use, conduct a trial run of the die. Observe the die’s operating status and processing effect to check whether its stability and precision meet the processing requirements.

- Timely Adjustment and Optimization: If any problems are found or the processing effect is not ideal during the trial run, stop the machine immediately for inspection. Make targeted adjustments to the die’s structure and parameters according to the cause of the problem to ensure the normal operation of the die.

- Second Trial Run Confirmation: After adjustment, conduct a second trial run. Carefully observe the die’s operating situation and processing effect to confirm that the adjustment results meet expectations, providing reliable guarantees for formal production.

After Installation: Meticulous Maintenance, Continuous Guarantees

Regular Inspection and Maintenance

After installation, establish a regular inspection system. Regularly check whether the fixing devices and connection components of the die are loose and whether the surface quality has changed. By promptly identifying and dealing with potential problems, ensure that the die is always in good operating condition.

Scientific Maintenance to Extend Service Life

Formulate a scientific and reasonable maintenance plan according to the die’s usage frequency and processing requirements. Regularly clean, lubricate, and tighten the die to reduce die wear, extend its service life, and lower production costs.

Standardized Operation to Ensure Safety

During the use of the die, strictly comply with operation specifications and safety requirements. Strengthen the training and management of operators to improve their skill levels and safety awareness, preventing die damage or safety accidents caused by improper operation.

The installation of a tungsten carbide die is a rigorous, meticulous, and interconnected process that must be carried out strictly in accordance with operating procedures and requirements. By making good preparations before installation, conducting precise operations during installation, and implementing effective maintenance and management after installation, the stability and precision of the die can be effectively guaranteed, improving processing efficiency and product quality. At the same time, paying attention to the training and management of operators is also the key to fully leveraging the die’s performance and enhancing the production efficiency of enterprises.

Related Posts

- Comprehensive Analysis of Techniques for Improving the Processing Efficiency of Tungsten Carbide Dies

- How Tungsten Carbide Die Realizes Harmonious Coexistence of Environmental Protection and High Efficiency

- Customized Tungsten Carbide Die: A Precise Process for Outstanding Quality

- Tungsten Carbide Die Maintenance and Repair