Carbide parts hole polishing with Ra0.015

Cheap processing factory. Carbide, as a material used in mold or mechanical parts, has been widely applied due to its wear resistance and high-temperature performance. However, in many cases,

Carbide, as a material used in mold or mechanical parts, has been widely applied due to its wear resistance and high-temperature performance. However, in many cases, there is a requirement for a mirror-like surface finish or smoothness for the parts or holes used. In such cases, it is necessary to polish the carbide. Our company can achieve a polishing precision of Ra0.015 for carbide holes.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Carbide is one of the hardest materials, with a hardness ranging from 85HRA to 95HRA. During the machining process, burrs are inevitably formed. The process of removing these burrs is also referred to as polishing. For parts with low smoothness requirements, oilstones are used for grinding, while sandpaper polishing is used for higher smoothness requirements. For carbide parts with a smoothness requirement of Ra0.015, diamond paste is used for polishing.

Polishing the surface of tungsten steel parts is generally easier to handle and convenient for inspection. Hole polishing requires polishing technicians with rich experience. Care should be taken during the polishing process to avoid exceeding the tolerance requirements specified in the drawings. The machining personnel should regularly inspect the parts to better control the quality.

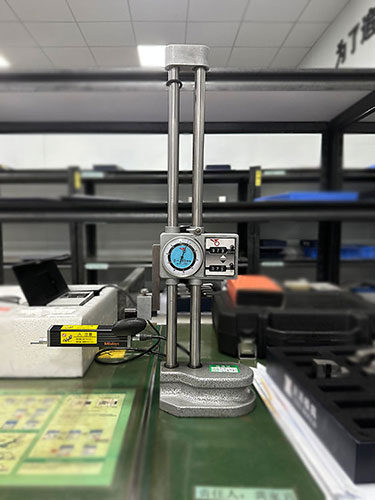

For the smoothness of carbide parts, we use smoothness testing instruments for inspection. Yize Mold Company provides full-process precision machining for carbide parts, with 16 years of part machining experience. We continuously update our equipment and improve our machining techniques. Please feel free to contact us.