Cleaning and Maintenance of Tungsten Carbide Dies: Professional Methods for Efficient Production

In the field of industrial production, tungsten carbide dies, with their excellent high hardness and wear resistance, have become indispensable key tools in numerous manufacturing processes. However, as the frequency […]

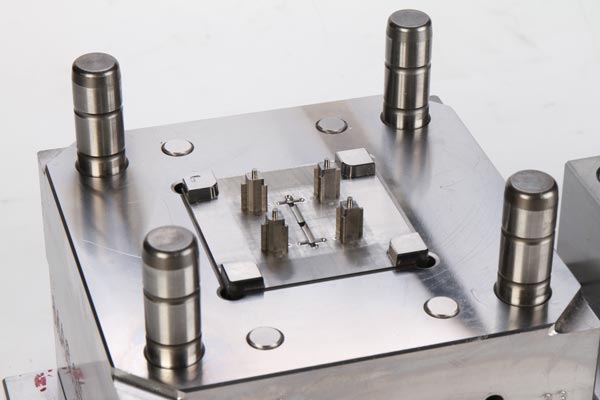

In the field of industrial production, tungsten carbide dies, with their excellent high hardness and wear resistance, have become indispensable key tools in numerous manufacturing processes. However, as the frequency of use increases, the dies are inevitably subject to contamination and wear. In this context, mastering scientific and correct cleaning and maintenance methods is of great significance for extending the service life of the dies, ensuring the stability of die precision, and improving overall production efficiency. This article will provide an in-depth analysis of the cleaning and maintenance essentials of tungsten carbide dies, offering professional and practical guidance to relevant practitioners.

I. Detailed Introduction to Cleaning Methods for Tungsten Carbide Dies

Ordinary Cleaning: The Basic Option for Daily Maintenance

During daily use, the surface of tungsten carbide dies is prone to attaching oil stains, dust, and other impurities. These contaminants not only affect the cleanliness of the die’s appearance but may also have a negative impact on the die’s performance and service life. Therefore, regular ordinary cleaning is highly necessary.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

For general contaminants, mild soapy water is an ideal cleaning agent. When performing the cleaning operation, fully immerse the die in warm water, add an appropriate amount of soap, and wait for the soap to dissolve completely. Then, use a soft cloth or sponge to gently wipe the surface of the die. It is crucial to avoid using rough cloths or tools to prevent scratching the die surface, which could affect its precision and quality. After cleaning, rinse the die thoroughly with a large amount of clean water to ensure no soap residue remains, and finally dry it with a clean, dry cloth.

Cleaning with Professional Cleaning Agents: A Powerful Solution for Stubborn Stains

When the stains on the die surface are relatively stubborn or a more thorough cleaning effect is required, professional cleaning agents become the preferred choice. These cleaning agents usually have stronger detergency and can effectively remove oil stains, fingerprints, and other hard-to-clean impurities from the die surface.

When using professional cleaning agents, be sure to follow the product instructions strictly. Generally, immerse the die in the cleaning agent for a certain period of time, with the immersion time determined according to the specific instructions of the cleaning agent. After immersion, rinse the die with clean water. Since different cleaning agents are suitable for different types of stains and materials, it is essential to fully consider the actual situation of the die when selecting a cleaning agent to ensure the selection of the most appropriate product.

Polishing Treatment: A Key Step to Restore the Die Surface’s Luster

For dies that have been used for a long time and have developed deep stains or oxidation, polishing treatment is an extremely effective deep-cleaning method. It can not only thoroughly remove stains and oxides from the die surface but also restore the surface’s luster and improve its appearance quality.

Polishing treatment requires the use of professional polishing agents and polishing tools. Before polishing, conduct a comprehensive cleaning of the die to remove most of the surface stains and prepare for the subsequent polishing process. Then, follow the instructions of the polishing agent for operation, strictly controlling the polishing time and force. Excessive polishing may cause damage to the die surface, affecting its precision and service life, so it should be carried out with caution.

II. Comprehensive Explanation of Maintenance Techniques for Tungsten Carbide Dies

Rust Prevention Treatment: Resisting the Corrosion of Humid Environments

Tungsten carbide dies are highly susceptible to rusting in humid environments, making rust prevention treatment a top priority in maintenance work. After cleaning, the die should be promptly dried of moisture and coated with anti-rust oil or anti-rust grease to form a protective film, preventing the die surface from coming into contact with air and moisture and thus rusting.

Anti-rust oil is suitable for dies stored for a short period, providing effective rust protection for a certain time. Anti-rust grease, on the other hand, is more suitable for dies stored for a long time, offering a more lasting protective effect. When applying the anti-rust agent, ensure that it evenly covers the die surface, forming a complete and dense protective film to avoid omissions or uneven application.

For dies that will not be used for a long time, it is recommended to adopt vacuum sealing or oil-coating rust prevention methods for long-term storage. Vacuum sealing can effectively isolate air and moisture, providing all-round protection for the die. Oil-coating rust prevention involves applying a thick layer of anti-rust grease on the die surface to prevent rusting and corrosion.

Avoiding Collisions and Scratches: Protecting the “Hard” Surface of the Die

Although tungsten carbide dies have high hardness, they still need to be protected from collisions or friction with other hard objects. During storage and use, handle the dies with care to prevent collisions between dies or contact with other hard objects, which could cause surface scratches or damage.

When handling and transporting the dies, be sure to take appropriate protective measures. For example, use dedicated die packaging boxes or foam pads to fix and cushion the dies, ensuring that they are not subject to external impacts during transportation and guaranteeing their safe delivery.

Regular Inspection and Maintenance: Timely Identification and Resolution of Problems

To maintain the good condition and performance of tungsten carbide dies, regular inspection and maintenance work are indispensable. The inspection mainly includes checking the wear condition of the die surface and whether there are any cracks, deformations, or other abnormalities.

Once problems are identified, take corresponding measures promptly for treatment. For minor wear, repair can be carried out; for severely damaged or irreparable parts, timely replacement should be made to ensure the normal use of the die. At the same time, regular maintenance of the die, such as applying anti-rust agents and tightening loose components, helps extend the die’s service life and improve production efficiency.

Correct Use and Storage: Creating a Favorable Usage Environment

When using tungsten carbide dies, it is essential to strictly follow the operating procedures to avoid overloading or违规操作 (which can be translated as “non-compliant operation”) to prevent die damage or performance degradation. Correct usage methods can fully leverage the performance advantages of the die and improve production quality and efficiency.

When storing the dies, choose an appropriate environment and method. High temperature, humidity, and other unfavorable factors can cause damage to the dies and affect their service life. Therefore, it is recommended to store the dies in a dry, well-ventilated place without direct sunlight, providing a stable and suitable storage environment for the dies and maintaining their good condition.

III. Conclusion and Prospects

Tungsten carbide dies, as important tools in industrial production, have their cleaning and maintenance work directly related to the smooth progress of production and the effective guarantee of product quality. Through the detailed introduction in this article, we have learned about various effective cleaning methods and practical maintenance techniques. In actual operation, appropriate cleaning methods and maintenance measures should be selected according to the actual situation and usage requirements of the dies, and operations should be carried out strictly in accordance with the operating procedures.

At the same time, regular inspection and maintenance are key links to ensure the stable performance of the dies. By promptly identifying and dealing with problems, the service life of the dies can be effectively extended, production efficiency can be improved, and production costs can be reduced. Only by attaching great importance to the cleaning and maintenance work of tungsten carbide dies can we fully leverage their advantages and create greater benefits and value for industrial production. In the future, with the continuous development of industrial technology, we look forward to the application of more advanced cleaning and maintenance technologies in the field of tungsten carbide dies, driving industrial production to a higher level.

Related Posts

- Analysis of Key Points in Cooling Channel Design for Tungsten Carbide Dies

- Usage Considerations of Tungsten Carbide Die in High-Intensity Working Environments

- Analysis of Strategies for Improving the Processing Efficiency of Tungsten Carbide Dies

- Analysis of Common Causes of Fracture in Tungsten Carbide Dies