Comprehensive Analysis of Wear Resistance Testing Methods for Tungsten Carbide Dies

I. Introduction: The Core Proposition of Performance Evaluation for Tungsten Carbide Dies As the “teeth” of modern precision machining, tungsten carbide dies, with their high hardness (HRA 88-93), excellent thermal […]

I. Introduction: The Core Proposition of Performance Evaluation for Tungsten Carbide Dies

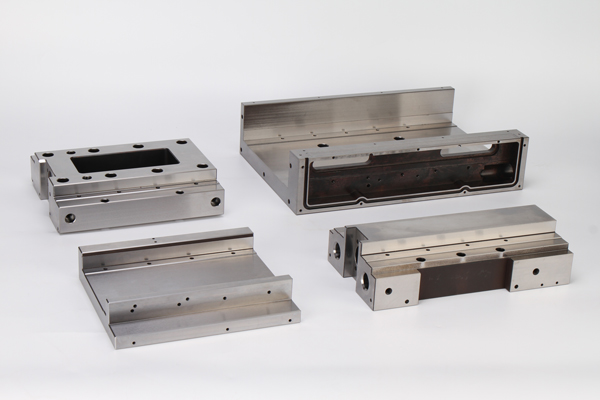

As the “teeth” of modern precision machining, tungsten carbide dies, with their high hardness (HRA 88-93), excellent thermal stability (withstanding temperatures up to 1,000°C), and superior wear resistance (50-100 times that of ordinary steel), have become indispensable tools across automotive manufacturing, aerospace, and electronics industries. However, since 60%-80% of a die’s service life depends on its wear resistance, establishing a scientific and precise testing system has emerged as a critical challenge for enhancing die quality and reducing production costs. This article systematically reviews four mainstream testing methods, offering in-depth analyses of their technical principles, operational essentials, and application scenarios to provide actionable testing solutions for the industry.

II. Industrial Value of Wear Resistance Testing

Wear resistance directly impacts three key performance indicators of dies:

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Service Life: A 10% improvement in wear resistance can extend die lifespan by 30%-50%.

- Machining Accuracy: Wear-induced dimensional deviations account for over 45% of product defects.

- Production Costs: Prolonging die replacement cycles reduces per-unit costs by 20%-35%.

Standardized testing enables precise matching of die materials, heat treatment processes, and operating conditions, avoiding both “over-engineering” and “underperformance” wastes.

III. Technical Analysis of Four Main Testing Methods

1. Friction and Wear Tester Method: Quantitative Evaluation Under Simulated Conditions

- Technical Principle: Utilizes pin-on-disk or ring-on-block configurations to simulate actual friction environments by controlling load (10-500 N), rotational speed (50-2,000 rpm), and temperature (room temperature to 800°C).

- Operational Essentials:

- Friction Pair Selection: Tungsten carbide balls (HRA 92) for high-hardness testing; silicon nitride ceramics (HRA 94) for high-temperature scenarios.

- Wear Measurement: Employ profilometers (0.1 μm precision) or weight-loss methods (0.1 mg precision).

- Advantages: Quantifies core parameters such as wear rate (mm³/N·m) and friction coefficient.

- Limitations: Laboratory conditions may deviate from actual operating conditions by 15%-25%.

2. Rockwell Hardness Testing Method: Rapid Screening Auxiliary Tool

- Technical Principle: Measures indentation depth under a 100 kgf load using a diamond indenter (120° cone angle) or tungsten carbide ball (1/16-inch diameter).

- Operational Essentials:

- Test Point Distribution: Randomly select 5-10 points on the die’s working surface with ≥3 mm spacing.

- Hardness Correlation: HRA values exhibit a positive correlation (coefficient 0.78) with wear resistance.

- Advantages: Completes single-point testing within 30 seconds, suitable for large-scale sampling.

- Limitations: Only reflects surface hardness; unable to evaluate deep-layer wear resistance.

3. Impact Wear Testing Method: Simulation of Extreme Operating Conditions

- Technical Principle: Uses drop-weight impact testers (5-500 J energy) or pneumatic impact devices to simulate impact wear during stamping or forging processes.

- Operational Essentials:

- Impact Parameters: Adjustable frequency (1-20 Hz) and angle (30°-90°).

- Damage Assessment: Employ ultrasonic flaw detection (0.1 mm detection depth) or metallographic analysis (crack propagation observation).

- Advantages: Reproduces fatigue wear processes under service conditions.

- Limitations: High equipment costs (¥500,000-2,000,000 per unit) and long testing cycles (72-168 hours).

4. Wear-Resistant Coating Testing Method: Specialized Evaluation for Surface Modifications

- Technical Principle: Evaluates PVD/CVD coatings (e.g., TiN, CrN, Al₂O₃) through scratch tests (critical load LC > 30 N) or reciprocating friction tests (5-50 mm stroke).

- Operational Essentials:

- Coating Thickness Control: 2-5 μm for PVD coatings; 8-20 μm for CVD coatings.

- Bond Strength Testing: Tensile method (≥50 MPa) or bending method (180° without delamination).

- Advantages: Quantifies interfacial bonding performance between coatings and substrates.

- Limitations: Requires specialized equipment (e.g., nano-scratch testers); high testing costs (¥2,000-5,000 per test).

IV. Strategic Selection of Testing Methods

1. Scenario-Based Matching Principles

| Testing Scenario | Recommended Method | Accuracy Level | Cost Index |

|---|---|---|---|

| Rapid Screening | Rockwell Hardness Testing | ★★☆ | ★☆☆ |

| General Wear Evaluation | Friction and Wear Tester | ★★★★ | ★★☆ |

| Extreme Condition Validation | Impact Wear Testing | ★★★★★ | ★★★★ |

| Coating Performance Evaluation | Wear-Resistant Coating Testing | ★★★★ | ★★★★ |

2. Combined Testing Protocol

- Phase 1 (Screening): Rockwell hardness testing to rapidly eliminate samples with insufficient hardness.

- Phase 2 (Detailed Evaluation): Friction and wear tester to obtain wear rate and friction coefficient data.

- Phase 3 (Validation): Impact wear testing for high-load scenarios or wear-resistant coating testing for surface-modified dies.

V. Conclusion: Three Development Trends in Testing Systems

- Intelligization: Integration of machine vision (automated wear area recognition) and AI algorithms (wear prediction models).

- Standardization: Promotion of localized applications of international standards such as ISO 26443.

- Integration: Development of multi-parameter coupled testing platforms (e.g., friction-impact composite testers).

By establishing a “laboratory testing + field validation” dual-loop system, the industry can transition from “empirical judgment” to “quantitative decision-making” in evaluating tungsten carbide die wear resistance, providing robust technical support for high-end equipment manufacturing.