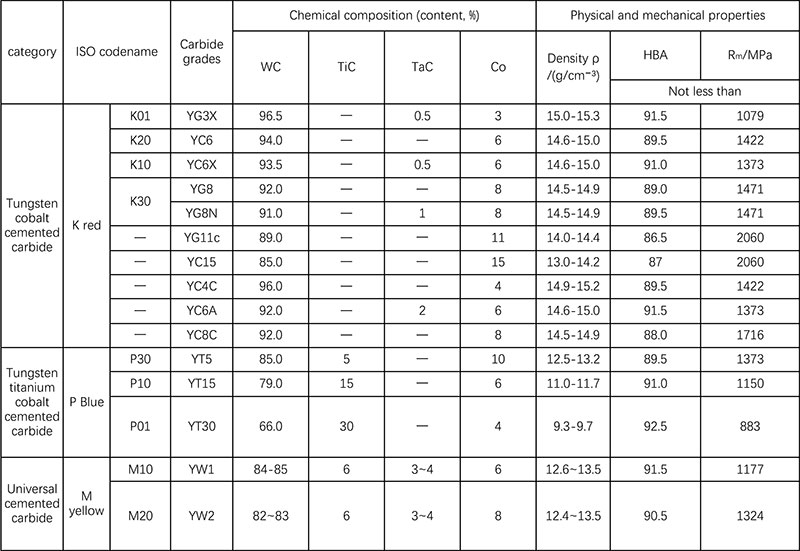

Common grades of china cemented carbide

Cheap processing factory. China-made cemented carbide offers high cost-effectiveness. For applications that do not require high performance of cemented carbide, choosing suitable grades of products is a good choice to save expenses.

China-made cemented carbide offers high cost-effectiveness. For applications that do not require high performance of cemented carbide, choosing suitable grades of products is a good choice to save expenses. Cemented carbide is a powder metallurgy material formed by mixing high-hardness, high-melting-point carbide powder with a binder, followed by pressing and sintering. The hardness of cemented carbide can reach 86-93 HRA at room temperature (equivalent to 69-81 HRC), and its hot hardness can reach 900-1000°C. Therefore, its cutting speed is 4-7 times higher than high-speed steel, and tool life is increased by 5-80 times. Due to the high hardness and brittleness of cemented carbide, it cannot be mechanically processed, so it is often made into shaped inserts and brazed onto tool bodies for use.

Commonly used cemented carbide grades in China can be divided into three categories based on composition and performance characteristics. The grades, chemical composition, and properties are shown in the table below.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Tungsten-cobalt (WC-Co) cemented carbide.

Its main chemical composition is tungsten carbide and cobalt. The grade is represented by the first letters of the pinyin “Ying” and “Cobalt” followed by the letter “YG” and a number. The number represents the percentage of cobalt content. Higher cobalt content results in better strength and toughness of the alloy, while lower cobalt content leads to higher hardness and better heat resistance. For example, YG6 represents a tungsten-cobalt cemented carbide with a cobalt content of 6%, and the rest is tungsten carbide. This type of alloy can also be represented by the code “K” and is marked in red.

Tungsten-cobalt-titanium (WC-Co-Ti) cemented carbide.

Its main components are tungsten carbide, titanium carbide, and cobalt. The grade is represented by the first letters of the pinyin “Ying” and “Titanium” followed by the letter “YT” and a number. The number represents the percentage of titanium carbide content. For example, YT15 represents a tungsten-cobalt-titanium cemented carbide with a titanium carbide content of 15%, and the rest is tungsten carbide and cobalt. This type of alloy can also be represented by the code “P” and is marked in blue.

YT series cemented carbide.

Has higher hardness and wear resistance due to the addition of titanium carbide. At the same time, a thin layer of titanium oxide film is formed on the surface of this type of alloy, which reduces chip adhesion during cutting and provides higher hot hardness. However, the strength and toughness of YT series cemented carbide are lower than that of YG series. Therefore, YG series cemented carbide is suitable for processing brittle materials such as cast iron, while YT series cemented carbide is suitable for processing ductile materials such as steel. Within the same category of cemented carbide, higher cobalt content is suitable for manufacturing roughing tools, while lower cobalt content is suitable for manufacturing finishing tools.

Universal cemented carbide.

It is a tungsten carbide (WC) cemented carbide that replaces the titanium carbide (TiC) in the YT series with tantalum carbide (TaC) or niobium carbide (NbC). Universal cemented carbide combines the advantages of the above two types of alloys and has a wide range of applications. Therefore, it is also called universal cemented carbide. The grade is represented by the first letters of the pinyin “Ying” and “Universal” followed by the letter “YW” and a number. The number has no special meaning and only represents the serial number of the alloy. It can also be represented by the code “M” and is marked in yellow.