How to Evaluate and Extend the Economic Life of Tungsten Carbide Die

Tungsten carbide die plays a pivotal role in the manufacturing industry due to its outstanding hardness, wear resistance, and stability. Given the direct impact of the die’s economic life on […]

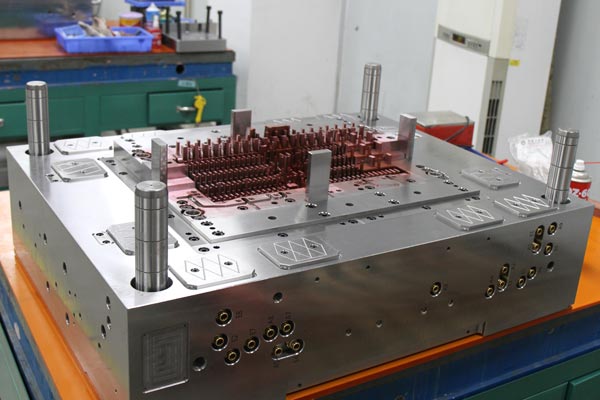

Tungsten carbide die plays a pivotal role in the manufacturing industry due to its outstanding hardness, wear resistance, and stability. Given the direct impact of the die’s economic life on production costs and efficiency, evaluating and extending its economic life has become a core concern in the manufacturing sector. The following will elaborate on evaluation methods and extension strategies in detail.

Evaluation of the Economic Life of Tungsten Carbide Die

Initial Quality Evaluation

The initial quality of a tungsten carbide die is the cornerstone of its economic life. During evaluation, attention should be paid to the material quality, manufacturing process, and precision of the die. High-quality raw materials are the premise for stable die performance. A fine manufacturing process ensures that the die components have accurate dimensions and good fit, and strict quality control can prevent potential defects in the die, laying a solid foundation for its long-term use.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Performance Evaluation

Performance evaluation covers key indicators such as the hardness, wear resistance, and impact resistance of the die. These performance characteristics directly determine the stability and durability of the die during use. With the help of professional testing equipment and methods, such as hardness testers and wear testing machines, the performance level of the die can be accurately measured to determine whether it meets production requirements.

Usage Environment Evaluation

The usage environment of the die has a significant impact on its economic life. During evaluation, it is necessary to comprehensively consider factors such as the working environment temperature, humidity, and corrosiveness, as well as the loads and impacts the die is subjected to. High temperatures, high humidity, or a strongly corrosive environment can accelerate the aging and corrosion of the die material, while excessive loads and frequent impacts will lead to increased wear of the die, shortening its service life.

Maintenance and Upkeep Evaluation

Good maintenance and upkeep are crucial for extending the die’s life. When evaluating the maintenance and upkeep of the die, check whether daily tasks such as cleaning, lubrication, and fastening are carried out properly, and whether plans for regular inspections and replacement of worn parts are effectively implemented. Regular cleaning can prevent impurities from entering the die and affecting its performance, proper lubrication can reduce friction and wear, and timely fastening can avoid die looseness that may cause failures.

Economic Benefit Evaluation

Economic benefit evaluation is an important part of determining the economic life of the die. By comparing the procurement cost, usage cost, maintenance cost, and replacement cost of the die, the overall economic benefits can be calculated. When the maintenance cost of the die exceeds the economic benefits it brings, it means that continuing to use this die is no longer economical, and consideration should be given to replacing it with a new one.

Strategies for Extending the Economic Life of Tungsten Carbide Die

Optimize Design and Material Selection

During the die design stage, emphasis should be placed on the rationality of the structure and the scientificity of material selection. Optimize the die structure to reduce stress concentrations and wear points, and improve the overall strength and wear resistance. At the same time, select high-quality tungsten carbide materials to ensure that the die has excellent physical and chemical properties, enhancing its service life from the source.

Rational Use and Operation

During use, strictly follow the operating procedures and avoid overloading and improper operations. Arrange production plans and process flows reasonably to ensure that the die operates under normal loads. Regularly train operators to improve their operating skills and die protection awareness, reducing die damage caused by improper operations.

Regular Maintenance and Inspection

Establish a comprehensive maintenance and upkeep system, and regularly clean, lubricate, and fasten the die. Replace severely worn parts in a timely manner according to the wear situation to ensure that the die is in good condition. Formulate and implement a regular inspection plan to conduct a comprehensive inspection and repair of the die,及时发现 (promptly detect) and deal with potential problems.

Technological Innovation and Upgrades

Pay attention to technological innovation and upgrade trends in the industry, and promptly introduce new technologies and materials. Adopt advanced surface treatment technologies, such as coating and carburizing, to improve the hardness and wear resistance of the die; apply intelligent monitoring systems to monitor the working status of the die in real time, provide early warnings of potential failures, and deal with them in a timely manner to extend the die’s service life.

Cost Control and Economic Benefit Analysis

When extending the economic life of the die, fully consider cost control and economic benefits. Compare and analyze the costs and benefits of different maintenance plans to select the optimal strategy. Establish an evaluation model for the service life and economic benefits of the die to provide a scientific basis for decision-making, ensuring the maximization of economic benefits while extending the service life.

Evaluating and extending the economic life of tungsten carbide die is an important topic in the manufacturing industry. Through comprehensive evaluation and effective strategies, the service life of the die can be extended, improving production efficiency and economic benefits. With the progress of science and technology and the development of the manufacturing industry, we should continue to pay attention to innovation trends and explore new methods and strategies to contribute to the sustainable development of the manufacturing industry.

Related Posts

- Secrets to Prolonging the Service Life of Tungsten Carbide Dies

- Tungsten Carbide Die: A “Potential Star” in the Environmental Protection Field

- Comprehensive Analysis of Key Points in Cooling Channel Design for Tungsten Carbide Dies

- Analysis and Countermeasures of Stress Concentration Problem in Tungsten Carbide Die