How to Prevent Vibration Problems of Tungsten Carbide Dies During Processing

I. Introduction Tungsten carbide dies play a pivotal role in industries such as metal processing and plastic molding due to their high hardness, excellent wear resistance, and superior mechanical properties. […]

I. Introduction

Tungsten carbide dies play a pivotal role in industries such as metal processing and plastic molding due to their high hardness, excellent wear resistance, and superior mechanical properties. However, during the die processing, vibration problems often emerge as a critical factor that restricts processing efficiency and affects product quality. Vibration not only accelerates die wear and reduces precision but may also trigger equipment failures and even pose a threat to operator safety. Therefore, effectively preventing vibration problems in tungsten carbide dies during processing has become an urgent issue. This article will explore strategies and methods for preventing vibration problems of tungsten carbide dies from the aspects of die design, processing equipment, processing technology, and operation management.

II. Die Design Optimization: Laying the Foundation for Vibration Prevention

Die design serves as the fundamental step in preventing vibration problems. When designing tungsten carbide dies, it is essential to fully consider their structural characteristics, material properties, and usage requirements, and optimize the die design to reduce vibration sources.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Rational Structural Design

The structural design of the die should be rational, avoiding overly complex structures or unnecessary protruding parts. Overly complex structures not only increase the processing difficulty but also tend to induce vibrations during processing. At the same time, it is crucial to ensure that the die has sufficient rigidity and stability to effectively resist vibrations caused by structural deformation. For example, when designing the supporting structure of the die, strengthening ribs or increasing the wall thickness can be used to enhance the overall rigidity of the die.

Precise Material Selection

Selecting the appropriate tungsten carbide material is a key step in preventing vibrations. The chosen material should possess sufficient strength and toughness to withstand the vibration impacts during processing. In addition, the heat treatment process of the material is also of great importance. Reasonable heat treatment can eliminate internal stresses in the material and improve the overall performance of the die. For instance, tungsten carbide materials that have undergone quenching and tempering treatments can achieve a good balance between hardness and toughness, thus better adapting to the vibration environment during processing.

Strict Precision Control

Precision control of the die is an important guarantee for preventing vibration problems. During the design process, strict control over the dimensional accuracy and surface quality of the die is necessary. Insufficient dimensional accuracy can lead to gaps between the die and equipment or other components during processing, thereby inducing vibrations; poor surface quality can increase friction, which may also trigger vibrations. Therefore, advanced processing technologies and detection equipment should be used to ensure that the die precision meets the design requirements.

III. Processing Equipment Selection and Debugging: Creating a Stable Processing Platform

The performance of processing equipment has a direct impact on preventing vibration problems. Selecting high-performance processing equipment and conducting reasonable debugging and maintenance are crucial for reducing vibration problems.

Appropriate Equipment Selection

Select suitable processing equipment according to specific processing requirements and die characteristics. The power, precision, and stability and other performance indicators of the equipment must meet the processing requirements to ensure a smooth processing process. For example, for tungsten carbide dies with high processing precision requirements, a machining center with a high-precision spindle and positioning system should be selected; for large-scale dies, a gantry machining center with high power and good rigidity should be chosen.

Precise Equipment Debugging

Before the equipment is put into use, precise debugging is essential. The debugging content covers various aspects such as the position, angle, and tightening degree of the equipment. Ensure that the equipment remains stable during operation to avoid vibrations caused by looseness or misalignment of the equipment itself. For example, when debugging the spindle of a machining center, professional detection instruments should be used to accurately measure and adjust the radial runout and axial end play of the spindle to meet the specified precision requirements.

Regular Equipment Maintenance

Regular maintenance and upkeep of processing equipment are important measures to maintain good equipment performance. Timely replacement of worn parts, such as bearings and ball screws, can prevent vibrations caused by part wear. At the same time, regularly inspect and clean the lubrication and cooling systems of the equipment to ensure that the equipment operates under optimal conditions. For example, regularly replace the lubricating oil and coolant of the machine tool and clean the impurities in the oil tank and cooling water tank to ensure good lubrication and cooling effects.

IV. Processing Technology Optimization: Exploring Ways to Reduce Vibration

Optimizing processing technology is an effective approach to reducing vibration problems. By adjusting processing parameters and improving processing methods, the vibration level during processing can be significantly reduced.

Scientific Adjustment of Cutting Parameters

Cutting parameters are important factors affecting processing vibrations. During processing, cutting speed, feed rate, and cutting depth should be reasonably adjusted according to factors such as the hardness of the material and the performance of the processing equipment. Excessive cutting speed or feed rate will increase the cutting force, thereby inducing vibrations; while an overly large cutting depth will subject the tool to excessive loads, which is also prone to causing vibrations. Therefore, through experiments and experience summarization, the optimal combination of cutting parameters should be found to reduce the cutting force and minimize vibrations.

Innovative Improvement of Processing Methods

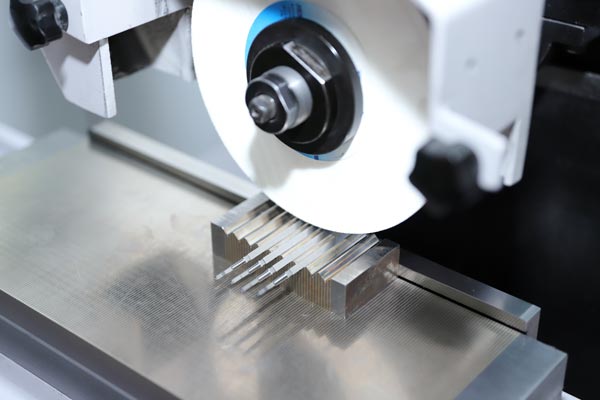

Adopting advanced processing methods can effectively improve processing efficiency and quality while reducing the vibration level. For example, high-speed cutting technology makes the cutting process more stable by increasing the cutting speed, reducing vibrations and cutting heat generation; precision grinding technology can achieve high-precision processing, reducing processing errors and thus vibrations caused by errors. In addition, vibration suppression technologies such as using vibrating tools and vibrating fixtures can also be adopted to actively control vibrations and reduce vibrations during processing.

Rational Use of Cutting Fluid

Cutting fluid plays an important role in cooling, lubricating, and cleaning during processing. Rational use of cutting fluid can reduce the cutting temperature and cutting force, thereby reducing vibrations. When selecting cutting fluid, appropriate types and concentrations should be chosen according to the material properties and processing requirements. For example, for processing tungsten carbide materials with high hardness and toughness, cutting fluids with good extreme-pressure lubrication performance should be selected; for dies with high processing precision requirements, cutting fluids with good cooling performance should be chosen. At the same time, attention should be paid to the supply method and flow rate of the cutting fluid to ensure that the cutting fluid can fully cover the processing area and exert the best effect.

V. Operation Management Standardization: Building a Defense Line against Vibration

Standardized operation management is an important guarantee for preventing vibration problems. By strengthening the training and management of operators and improving operation levels, vibrations caused by human factors can be effectively reduced.

Professional Training for Operators

Conduct systematic training for operators to enable them to have an in-depth understanding of the processing characteristics of tungsten carbide dies and the hazards of vibration problems. The training content should include the operation methods of processing equipment, the key points of mastering processing technology, and safety operation procedures. Through training, improve the skill level and sense of responsibility of operators, enabling them to operate the equipment correctly and carry out processing in strict accordance with technological requirements, thus reducing vibrations caused by improper operation.

Standardized Formulation of Operation Specifications

Formulate detailed operation procedures and standards, clearly specifying the operation methods of processing equipment, the setting ranges of cutting parameters, and the requirements for using cutting fluid. The operation procedures should be operable and targeted, providing clear guidance for operators. At the same time, post the operation procedures at the processing site for operators to refer to and follow at any time.

Regular Implementation of Supervision and Inspection

Establish a sound supervision and inspection mechanism to conduct regular or irregular supervision and inspection of the operation behaviors of operators. The inspection content includes whether operators operate in accordance with the operation procedures, whether the equipment operates normally, and whether the processing quality meets the requirements. Promptly deal with and correct problems found, and seriously criticize and educate violation operation behaviors to prevent vibration problems.

VI. Conclusion

Preventing vibration problems of tungsten carbide dies during processing is a systematic and complex task that requires a comprehensive approach from multiple aspects such as die design, processing equipment, processing technology, and operation management. By optimizing die design, selecting high-performance processing equipment and conducting precise debugging, optimizing processing technology, and standardizing operation management, the vibration level during processing can be effectively reduced, improving processing efficiency and product quality. At the same time, these measures can also extend the service life of dies, reduce production costs, and improve the economic benefits of enterprises. Therefore, when customizing and using tungsten carbide dies, enterprises and individuals should attach great importance to the prevention of vibration problems and implement various preventive measures to ensure the smooth progress of the processing process and contribute to the development and progress of the industry.