Innovative Design of Tungsten Carbide Die

Introduction In the context of the rapid advancement of industrial technology, the die industry, as a key pillar of the manufacturing sector, plays a decisive role in product quality and […]

Introduction

In the context of the rapid advancement of industrial technology, the die industry, as a key pillar of the manufacturing sector, plays a decisive role in product quality and production efficiency through its technological innovation and capabilities. Tungsten carbide die, with its excellent properties such as high hardness, high wear resistance, and high thermal stability, holds a significant position in the die field. However, with the increasingly fierce market competition and the rising demands of consumers for product quality, traditional design methods for tungsten carbide die are no longer able to meet the requirements of modern manufacturing. Therefore, innovative design of tungsten carbide die has become the key to promoting the development of the die industry.

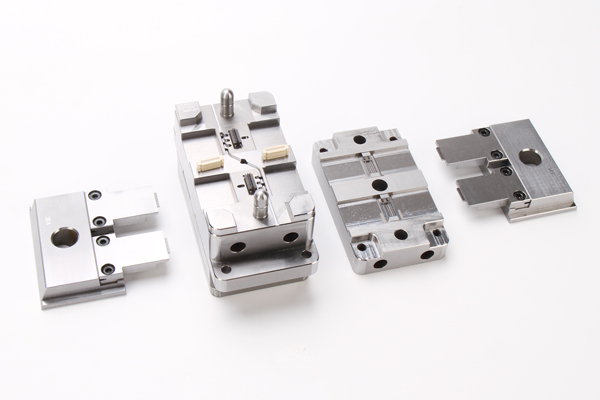

Analysis of the Characteristics and Applications of Tungsten Carbide Die

Tungsten carbide, also known as hard alloy, is a composite material formed by sintering tungsten carbide (WC) particles and metal binders (such as cobalt, nickel, etc.) at high temperatures. Its unique microstructure endows tungsten carbide with extremely high hardness and excellent wear resistance, enabling it to withstand significant pressure and friction, and thus it is widely used in die manufacturing.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Tungsten carbide die is mainly used for manufacturing high-precision and high-standard plastic products, rubber products, and metal die-castings. In the automotive industry, it can be used to produce key components such as engine parts and body structural parts, ensuring the reliability and safety of automobiles. In the electronics sector, it can precisely manufacture molds for various electronic components, meeting the development trend of miniaturization and precision in electronic products. In the home appliance industry, it provides high-quality mold solutions for the outer shells and internal parts of refrigerators, washing machines, and other home appliances. In the aviation field, relying on its outstanding performance, it assists in the manufacturing of aviation component molds, safeguarding the safety and stability of aircraft.

Explanation of the Necessity of Innovative Design of Tungsten Carbide Die

From the Perspective of Improving Product Quality

Innovative design can deeply optimize the die structure, enhancing its precision and stability from detailed aspects. Through precise structural design, it reduces deformation and errors during the die’s operation, thereby ensuring that the produced products have a high degree of consistent quality and meeting the market’s strict requirements for high-quality products.

In Terms of Reducing Production Costs

Guided by the concept of innovative design, the manufacturing process of the die can be comprehensively optimized. This includes rational planning of material usage to reduce material consumption and optimizing the processing flow to minimize processing steps and time, thus effectively lowering processing costs. At the same time, it improves production efficiency and shortens the production cycle, further reducing the unit production cost.

From the Angle of Meeting Market Demands

As consumer demands become increasingly diverse and personalized, traditional die design can no longer meet the ever-changing market requirements. Innovative design can provide a wide range of customized mold solutions. According to the specific needs of different customers, it can quickly design molds that meet the requirements, thereby gaining an advantage in the fierce market competition.

Regarding Enhancing Enterprise Competitiveness

Innovative design is an important part of an enterprise’s technological innovation system. Through continuous innovative design of tungsten carbide die, enterprises can continuously improve their core competitiveness, form technological differentiation advantages, attract more customers, and enhance their话语权 (right to speak) and competitiveness in the market.

Exploration of the Ideas and Methods of Innovative Design of Tungsten Carbide Die

Modular Design Strategy

Modular design involves decomposing the die into multiple independent modules, each with specific functions and structures. By flexibly combining and replacing these modules, customized and serialized production of the die can be quickly achieved. This design approach not only significantly improves the flexibility and adaptability of the die but also effectively reduces its manufacturing and maintenance costs. For example, when production requirements change, only some modules need to be replaced instead of redesigning the entire die, greatly shortening the production preparation time.

Simulation Optimization Design Method

By using advanced simulation software, a comprehensive simulation analysis of the die’s stress, deformation, and wear during operation can be carried out. Through the simulation results, the weak links and potential problems in the die design can be accurately identified, and targeted optimization and improvement can be made. Simulation optimization design greatly improves the accuracy and reliability of die design, reduces the number of die trials, lowers die trial costs, and shortens the product time-to-market.

Intelligent Design Path

Make full use of cutting-edge technologies such as artificial intelligence and big data to achieve intelligent and automated die design. By collecting and analyzing a large amount of die design data, a knowledge base and model library for die design can be constructed, providing intelligent auxiliary decision-making and support for die design. Intelligent design can significantly improve the efficiency and quality of die design, reduce design errors caused by human factors, shorten the design cycle, and lower design costs.

Green and Environmentally Friendly Design Concept

During the die design process, fully consider environmental protection factors, select environmentally friendly materials, and adopt green manufacturing processes to reduce pollution and waste emissions from the source during die manufacturing. At the same time, by optimizing the die structure and extending its service life, the frequency of die replacement can be reduced, and the amount of waste generated can be decreased, achieving green and sustainable development of die manufacturing and meeting the strict requirements of today’s society for environmental protection.

Presentation of Practical Cases of Innovative Design of Tungsten Carbide Die

Take a certain automotive parts manufacturer as an example. When producing automotive engine parts, the enterprise actively adopted an innovatively designed tungsten carbide die. This die used the modular design concept, decomposing the die into multiple independent modules, each with specific functions and structures. By flexibly combining and replacing the modules, the die could quickly adapt to the production requirements of different models of engine parts, greatly improving production flexibility and efficiency.

At the same time, the die also integrated simulation optimization design and intelligent design technologies. Through simulation analysis, the weak links in the die design were accurately identified and targeted optimization and improvement were made, effectively enhancing the reliability and stability of the die. With the help of intelligent design methods, the design efficiency and quality were improved, and the design cycle and cost were reduced.

In practical applications, this innovatively designed tungsten carbide die achieved remarkable results. It not only significantly improved product quality and production efficiency but also effectively reduced production costs and the number of die trials, bringing considerable economic and social benefits to the enterprise and fully proving the feasibility and effectiveness of innovative design of tungsten carbide die.

Conclusion and Prospect

Innovative design of tungsten carbide die is the core driving force for the development of the die industry. Through the application of a series of innovative ideas and methods such as modular design, simulation optimization design, intelligent design, and green and environmentally friendly design, the performance and quality of tungsten carbide die can be significantly improved, meeting the market’s urgent demands for high precision, high efficiency, and environmental protection and energy conservation.

Looking ahead, with the continuous progress of science and technology and the continuous changes in the market, the innovative design of tungsten carbide die will continue to develop in depth. New design concepts, technologies, and materials will continue to emerge, providing broader space and stronger support for the innovative design of tungsten carbide die. Innovative design of tungsten carbide die will continue to provide solid support for the transformation and upgrading and sustainable development of the manufacturing industry, helping the manufacturing industry move towards a higher development stage.