The Market Prospect of Tungsten Carbide Processing Industry

In the grand landscape of the manufacturing industry, tungsten carbide shines like a brilliant star. With its excellent properties such as high strength, high hardness, wear resistance, heat resistance, and […]

In the grand landscape of the manufacturing industry, tungsten carbide shines like a brilliant star. With its excellent properties such as high strength, high hardness, wear resistance, heat resistance, and corrosion resistance, it plays an irreplaceable role in numerous fields. The tungsten carbide processing industry, as a crucial branch of the manufacturing sector, is closely linked to the overall development trend of manufacturing. This article will conduct an in-depth analysis of the market prospect of the tungsten carbide processing industry from multiple dimensions, including market demand, technological progress, policy environment, competitive landscape, and future development trends.

Market Demand: Continuously Rising with Immense Potential

Against the backdrop of global economic recovery and the vigorous development of the manufacturing industry, the tungsten carbide processing industry has ushered in an unprecedented golden era of development. The manufacturing sector’s increasingly stringent requirements for product precision, efficiency, and reliability have directly driven the soaring demand for tungsten carbide products. In the automotive manufacturing field, high-precision tungsten carbide cutting tools can ensure the precise machining of components, enhancing the overall performance of vehicles. In the aerospace industry, tungsten carbide molds, with their outstanding wear resistance and heat resistance, provide reliable guarantees for the forming of complex components. The mold manufacturing industry also shows a strong preference for tungsten carbide products, as their high precision and long service life are key to improving production efficiency.

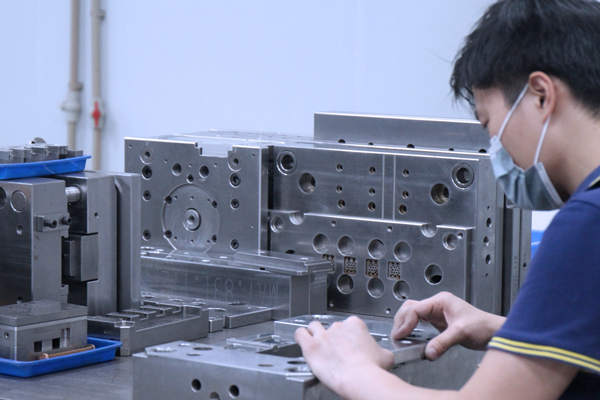

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

At the same time, the continuous emergence of new materials and technologies has opened up new application areas for the tungsten carbide processing industry. The rise of the new energy sector has led to increasing applications of tungsten carbide in battery manufacturing and solar energy equipment. The growing demand for high-efficiency filtration materials in the environmental protection field has also created new market space for tungsten carbide products. Therefore, from the perspective of market demand, the future of the tungsten carbide processing industry is extremely bright, with vast market potential.

Technological Progress: Innovation-Driven, Leading Transformation

Technological progress is the core driving force for the development of the tungsten carbide processing industry. As the manufacturing sector’s requirements for the performance of tungsten carbide products continue to rise, tungsten carbide processing technologies are also constantly innovating and breaking through. The application of high-precision and high-efficiency processing equipment and advanced processes has achieved a qualitative leap in the processing precision and efficiency of tungsten carbide products. For example, advanced CNC machining centers can realize the precision machining of complex-shaped tungsten carbide products, significantly shortening the production cycle and improving product quality.

The introduction of new materials and technologies has also brought new development opportunities to the tungsten carbide processing industry. Laser processing technology, with its characteristics of high precision and non-contact processing, demonstrates huge advantages in the micro-machining of tungsten carbide products. The application of nano-processing technology has significantly improved the surface properties of tungsten carbide products, further enhancing their wear resistance and corrosion resistance. These advanced technologies not only make the manufacturing process of tungsten carbide products more environmentally friendly, efficient, and precise but also offer more innovation possibilities for the industry.

Policy Environment: Favorable Policies Abound, Providing Strong Support

The policy environment plays an important supporting and guiding role in the development of the tungsten carbide processing industry. In recent years, governments around the world have successively introduced a series of policy measures to encourage the development of the manufacturing industry, providing broad development space for the tungsten carbide processing industry. The Chinese government’s “Made in China 2025” strategy regards the manufacturing industry as a pillar of the national economy and has increased support for technological innovation and industrial upgrading in the manufacturing sector, offering strong policy impetus for the development of the tungsten carbide processing industry.

At the same time, the growing global emphasis on and regulation of environmental protection and energy conservation have also prompted the tungsten carbide processing industry to move towards a green and sustainable development path. Governments around the world have formulated strict environmental protection standards and incentive policies to guide enterprises to adopt environmentally friendly materials and processes and reduce the emission of waste and pollutants. This provides strong guarantees for the sustainable development of the tungsten carbide processing industry and also creates new development opportunities for enterprises.

Competitive Landscape: Fierce Competition, Survival of the Fittest

With the continuous growth of market demand and rapid technological progress, competition in the tungsten carbide processing industry is becoming increasingly fierce. Domestic and foreign enterprises are纷纷 increasing their investments to improve product quality and technological levels in order to compete for market share. On the one hand, large enterprises, with their strong technological strength, complete production systems, and extensive sales networks, dominate the market. On the other hand, small and medium-sized enterprises seek breakthroughs and development through differentiated competition strategies, focusing on specific fields or niche markets.

In addition, the global economic recovery and the rapid development of the manufacturing industry have attracted many new competitors to enter the market. These new entrants bring new technologies and concepts, further intensifying market competition. Therefore, tungsten carbide processing enterprises need to continuously improve their core competitiveness, strengthen technological innovation and brand building, optimize production management and cost control to cope with the increasingly fierce market competition.

Future Trends: Diversified Development with a Promising Future

High-End and Intelligent Development

As the manufacturing sector’s requirements for the performance of tungsten carbide products continue to increase, the tungsten carbide processing industry will move towards high-end and intelligent development. High-end products will place greater emphasis on improving quality, precision, and reliability to meet the needs of high-end manufacturing for precision components. Intelligent production will widely apply automation, digitalization, and intelligent technologies to achieve real-time monitoring and optimization of the production process, improving production efficiency and product quality stability.

Green and Environmentally Friendly Transformation

Against the backdrop of increasing global environmental awareness, the tungsten carbide processing industry will accelerate its transformation towards green and environmentally friendly development. Enterprises will actively adopt environmentally friendly materials and processes, strengthen the recycling of waste and the treatment of pollutants, and reduce the environmental impact during the production process. At the same time, they will develop tungsten carbide products with environmental protection properties to meet the market demand for green products.

Diversified and Customized Expansion

The diversification and personalization of market demand will drive the tungsten carbide processing industry to develop towards diversification and customization. Enterprises need to continuously expand new application areas and product categories and develop tungsten carbide products suitable for different industries. At the same time, they should strengthen their customized production and service capabilities, providing personalized solutions according to customers’ specific needs to improve customer satisfaction and market competitiveness.

Summary and Suggestions

In conclusion, the tungsten carbide processing industry has a broad market prospect, but it also faces fierce market competition and constantly changing market demands. Tungsten carbide processing enterprises should actively respond to challenges and seize development opportunities. On the one hand, they should increase investment in technological innovation, improve product quality and technological levels, strengthen brand building, and enhance their core competitiveness. On the other hand, they should closely monitor changes in the policy environment and market trends, timely adjust their development strategies and business models, and actively expand new application areas and market space.

In addition, enterprises should also strengthen their environmental awareness, promote green production and sustainable development, and strengthen talent cultivation and introduction to build high-quality technical and management teams. Only through continuous innovation and progress can tungsten carbide processing enterprises stand invincible in the fierce market competition and achieve sustainable and healthy development of the industry.