Troubleshooting Methods for Common Faults of Tungsten Carbide Dies

I. Introduction Tungsten carbide dies possess characteristics such as high hardness, high strength, and wear resistance, playing a crucial role in the forming and processing of materials like plastics and […]

I. Introduction

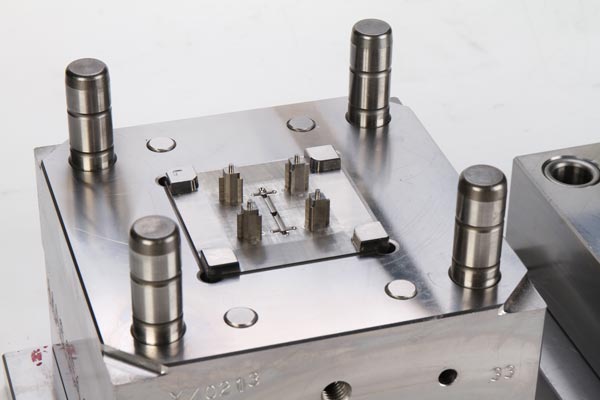

Tungsten carbide dies possess characteristics such as high hardness, high strength, and wear resistance, playing a crucial role in the forming and processing of materials like plastics and metals. However, due to various factors during use, tungsten carbide dies may encounter various faults, which in turn affect production efficiency and product quality. This article will analyze the common faults of tungsten carbide dies and propose corresponding troubleshooting methods to help users quickly resolve issues and ensure smooth production.

II. Common Faults and Cause Analysis of Tungsten Carbide Dies

Die Wear

After long-term use, tungsten carbide dies will experience surface wear due to continuous friction and collision with the forming materials. When the wear is severe, the dimensional accuracy and surface quality of the die will be affected, leading to product defects.

Cause analysis:

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Improper selection of die material, with insufficient hardness or toughness.

- The forming material has excessively high hardness or contains impurities, increasing wear.

- Improper use of the die, such as poor lubrication and insufficient cooling.

Die Deformation

During the use of the die, deformation may occur due to factors such as high temperature and high pressure. A deformed die cannot guarantee the dimensional accuracy and shape of the product, seriously affecting product quality.

Cause analysis:

- Unreasonable die design, such as uneven wall thickness and improper structure.

- Improper control of the forming temperature, with the temperature being too high or too low.

- Insufficient preheating of the die, resulting in uneven heating.

Die Cracking

Tungsten carbide dies may sometimes crack during use. A cracked die cannot be used continuously and needs to be replaced or repaired.

Cause analysis:

- There are internal defects in the die material, such as pores and inclusions.

- Excessive impact force or vibration is applied to the die during the forming process.

- Improper cooling method of the die, leading to stress concentration.

Material Adhesion on the Die

During the forming process, the forming material may adhere to the surface of the die, making it difficult for the product to be demolded. Material adhesion not only affects production efficiency but may also damage the surface of the die.

Cause analysis:

- Improper selection of the forming material, which is incompatible with the die material.

- Improper control of the forming temperature, with the temperature being too high and causing excessive melting of the material.

- Poor lubrication on the surface of the die, leading to material adhesion.

III. Troubleshooting Methods for Common Faults of Tungsten Carbide Dies

Troubleshooting Methods for Die Wear

Select appropriate tungsten carbide materials to ensure that the die has sufficient hardness and toughness. Choose suitable forming materials and avoid using materials with excessively high hardness or containing impurities. Strengthen the lubrication and cooling of the die to reduce the wear rate. Regularly inspect the wear condition of the die and promptly replace severely worn parts.

Troubleshooting Methods for Die Deformation

Optimize the die design to ensure a reasonable die structure and uniform wall thickness. Strictly control the forming temperature to avoid temperatures that are too high or too low. Strengthen the preheating of the die to ensure uniform heating. For deformed dies, heat treatment methods can be used for correction.

Troubleshooting Methods for Die Cracking

Select high-quality tungsten carbide materials to avoid using materials with internal defects. Optimize the forming process to reduce the impact force and vibration applied to the die. Reasonably design the die cooling system to avoid stress concentration. For cracked dies, welding repair or replacement of damaged parts can be carried out.

Troubleshooting Methods for Material Adhesion on the Die

Select forming materials that are compatible with the die material. Strictly control the forming temperature to avoid excessive melting of the material due to high temperatures. Strengthen the lubrication treatment on the surface of the die to reduce material adhesion. For adhered materials, mechanical or chemical cleaning methods can be used for treatment.

IV. Preventive Measures and Daily Maintenance

To reduce the incidence of faults in tungsten carbide dies and extend their service life, in addition to the above troubleshooting methods, the following preventive and daily maintenance measures should also be taken:

Preventive Measures

Fully consider factors such as material selection, structural design, and forming process during the die design stage to ensure that the die has sufficient strength and stability. Select high-quality tungsten carbide materials and forming materials to avoid faults caused by low-quality materials. Strictly control the forming process parameters, such as temperature, pressure, and speed, to ensure a stable and reliable forming process.

Daily Maintenance

Regularly clean and inspect the die to ensure that its surface is clean and free of impurities. Regularly check the lubrication and cooling systems of the die to ensure good lubrication and cooling effects. Regularly maintain and repair the die, such as replacing worn parts and repairing damaged parts. Establish a die usage file to record the usage and maintenance conditions of the die, providing a basis for troubleshooting and preventive maintenance.

V. Conclusion

Tungsten carbide dies may encounter various faults during use, affecting production efficiency and product quality. By understanding the causes of common faults and adopting corresponding troubleshooting methods, fault issues can be quickly resolved and production can be guaranteed to proceed smoothly. At the same time, strengthening preventive measures and daily maintenance can reduce the incidence of faults and extend the service life of the die. In practical applications, users should select appropriate troubleshooting and maintenance methods according to specific circumstances to ensure that tungsten carbide dies can exert their maximum efficiency in production.

Related Posts

- Application Characteristics of Tungsten Carbide Die in the Plastic Products Industry

- How Tungsten Carbide Dies Cope with Extreme Working Environments

- A Comprehensive Overview of Nickel Carbide Die Parts Machining

- How to Comprehensively Evaluate the Quality of Tungsten Carbide Dies from Different Manufacturers