Tungsten Carbide Die: An Excellent Choice for High-Strength Working Environments

In the era of rapid modern industrial development, dies play an increasingly crucial role in various manufacturing fields. Especially in high-strength working environments, the performance of dies directly determines the […]

In the era of rapid modern industrial development, dies play an increasingly crucial role in various manufacturing fields. Especially in high-strength working environments, the performance of dies directly determines the level of production efficiency and product quality. Among numerous die materials, tungsten carbide die stands out with its unique physical and chemical properties, becoming an ideal choice for many industries in high-strength working environments.

I. The Unique Basic Characteristics of Tungsten Carbide Die

Tungsten carbide, also known as hard alloy, is a sintered composite material made mainly of tungsten carbide through powder metallurgy processes, with a small amount of other metal carbides and bonding metals added. This material possesses a series of remarkable characteristics, such as high hardness, high strength, wear resistance, heat resistance, and corrosion resistance. These characteristics collectively enable tungsten carbide die to maintain excellent performance in high-strength working environments.

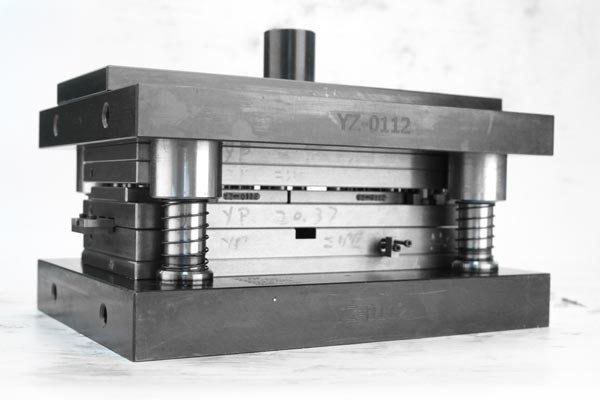

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

High Hardness: A Solid Defense Against Scratching

High hardness is one of the key advantages of tungsten carbide as a die material. In high-strength working environments, dies inevitably come into contact with the processed materials. The high hardness allows the die to effectively resist the indentation and scratching by the processed materials. This not only ensures that the precision of the die cavity remains at a high level but also guarantees its surface finish. As a result, the service life of the die is significantly extended, and the frequency of maintenance and replacement is greatly reduced, thereby effectively improving production efficiency.

High Strength and Wear Resistance: A Reliable Guarantee Against External Forces

In high-strength working scenarios, dies need to withstand enormous pressure and friction. The high strength of tungsten carbide enables it to easily resist these external forces, effectively preventing the die from deforming or being damaged. At the same time, its excellent wear resistance can minimize the wear of the die during use, ensuring that the precision and stability of the die are not affected, providing a solid guarantee for the smooth progress of production.

Heat Resistance: A Stable Guardian in High-Temperature Environments

Many traditional die materials will soften or deform in high-temperature working environments, leading to die failure. However, tungsten carbide has outstanding heat resistance. Even in high-temperature environments, it can maintain the stability of its hardness and rigidity and is not prone to softening or deformation. This characteristic makes it an ideal die material for high-temperature working environments, offering a reliable solution for high-temperature operations.

II. Diverse Application Examples of Tungsten Carbide Die in High-Strength Working Environments

Stamping Die: A Stable Pioneer under High-Speed and High-Pressure Conditions

In the stamping process, dies need to withstand the intense impact of high speed and high pressure. Tungsten carbide stamping dies, relying on their high strength and high wear resistance, can maintain a stable state for a long time under such extreme working conditions. This not only greatly improves the quality of stamped parts but also significantly reduces the maintenance and replacement costs of the dies, bringing higher benefits to stamping production.

Injection Mold: A Quality Defender in Harsh Environments

In the plastic injection molding industry, dies face multiple challenges from high temperature, high pressure, and corrosive plastic raw materials. The heat resistance and corrosion resistance of tungsten carbide injection molds enable them to cope with these harsh environments with ease, ensuring that the precision and quality of injection-molded products meet high standards, providing strong support for the high-quality production of plastic products.

Forging Die: A Precision Adherent under Extreme Conditions

During the forging process, dies need to withstand extremely high temperatures and pressures. Tungsten carbide forging dies, with their high hardness and high strength, can withstand these extreme conditions while always maintaining the precision and stability of the dies. This not only improves the quality of forged products but also enhances production efficiency, injecting strong impetus into the development of the forging industry.

III. Careful Maintenance and Upkeep of Tungsten Carbide Die

Although tungsten carbide die has excellent performance, proper maintenance and upkeep are still indispensable in high-strength working environments. Firstly, regularly cleaning the surface of the die to thoroughly remove attached dirt and residues is an important step in maintaining die performance. Secondly, regularly checking the wear condition of the die and promptly repairing or replacing damaged parts when found can extend the service life of the die. In addition, reasonably controlling the temperature and humidity in the working environment to prevent the die from being subjected to unnecessary thermal stress and corrosion is also a key measure for die maintenance.

IV. Conclusion

In conclusion, tungsten carbide die demonstrates unparalleled excellent performance in high-strength working environments. Its characteristics of high hardness, high strength, wear resistance, heat resistance, and corrosion resistance make it the first choice of die material for many industries. Through scientific and reasonable maintenance and upkeep, tungsten carbide die can maintain stable performance in high-strength working environments for a long time, thereby improving production efficiency, reducing production costs, and creating more considerable economic value for enterprises. With the continuous progress of science and technology and the sustained and rapid development of industry, the application fields of tungsten carbide die will inevitably further expand, and its performance in high-strength working environments will also gain wider recognition and application, contributing greater strength to the development of modern industry.